Injection moulds are essential tools in manufacturing, shaping molten plastic into desired forms for mass production, ensuring precision and efficiency.

Injection moulds create consistent and precise plastic parts by injecting molten plastic into a mold cavity. They are used in industries like automotive, electronics, and medical devices. The key benefits include high repeatability, fast production, and complex design capabilities.

Understanding the fundamental role of injection moulds is crucial for optimizing production efficiency. Explore how different types of moulds can impact your manufacturing process and part quality.

Injection moulds ensure high precision in mass production.True

Injection moulds are designed for high accuracy, creating parts that meet strict specifications, enhancing consistency in large-scale production.

Injection moulds are only used for plastic parts.False

While plastic is the most common material, injection moulds can also be used for metals, ceramics, and other materials, expanding their versatility across industries.

What is the Definition of Injection Molds?

Injection molds are tools used in the injection molding process to shape molten materials into specific forms. They play a critical role in manufacturing plastic parts across various industries.

Injection molds are precision tools used in injection molding to shape molten plastic into desired parts. They consist of two main halves, and are essential for producing consistent, high-quality parts in large volumes.

Injection molding is a tool for making plastic products. It’s also a tool that gives plastic products a complete structure and precise size. Injection molding is a processing method used in mass production of certain parts with complex shapes.

Specifically, it refers to the high-pressure injection of heated and melted plastic into the mold cavity by the injection molding machine, and after cooling and solidification, a molded product is obtained.

Injection molds are essential for mass production of plastic parts.True

Injection molds allow manufacturers to produce large volumes of consistent, high-quality plastic parts efficiently.

Injection molds are always made of metal.False

While metal is commonly used for injection molds, certain applications may require molds made from other materials like silicone or aluminum, depending on cost and part complexity.

What is the Working Principle of Injection Molds?

Injection molds are a vital part of the manufacturing process, shaping plastic into desired forms by injecting molten material into a mold cavity.

Injection molds work by injecting molten plastic into a mold cavity, where it cools and solidifies. The process allows for precise, high-volume production of plastic parts across industries like automotive, consumer goods, and medical devices.

Injection molding is a process of heating thermoplastics and making the things you want by injecting them into a mold. Here’s how it works: You put the thermoplastic pellets into the heating barrel through the screw of the injection molding machine1

The thermoplastic pellets get heated and melted in the heating barrel. When the plastic is all melted and gets to a certain injection pressure2 , it gets pushed into the mold you made in the injection molding machine through the injection head. Then it cools down and turns into the shape you want in the mold.

The injection mold works by using the mold’s cavity and heating system to heat the plastic, and then injecting it into the mold’s cavity at a certain pressure to form the desired molded product. The mold is the most important part of this process. The mold’s structure and manufacturing quality directly affect the quality and precision of the injection molded product.

Injection molds are essential for high-volume production.True

Injection molds allow for rapid and consistent production of complex plastic parts, making them indispensable for industries requiring high-volume manufacturing.

Injection molds are only used for plastic parts.False

While injection molds are commonly used for plastic, they can also be used with materials like metals and rubber, depending on the type of mold and process.

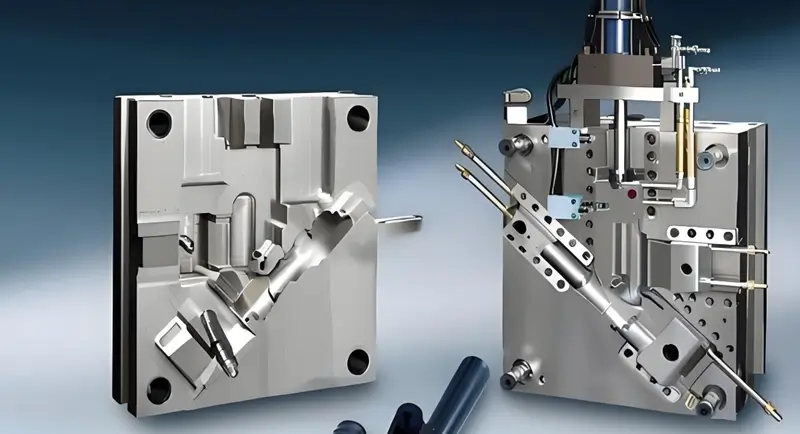

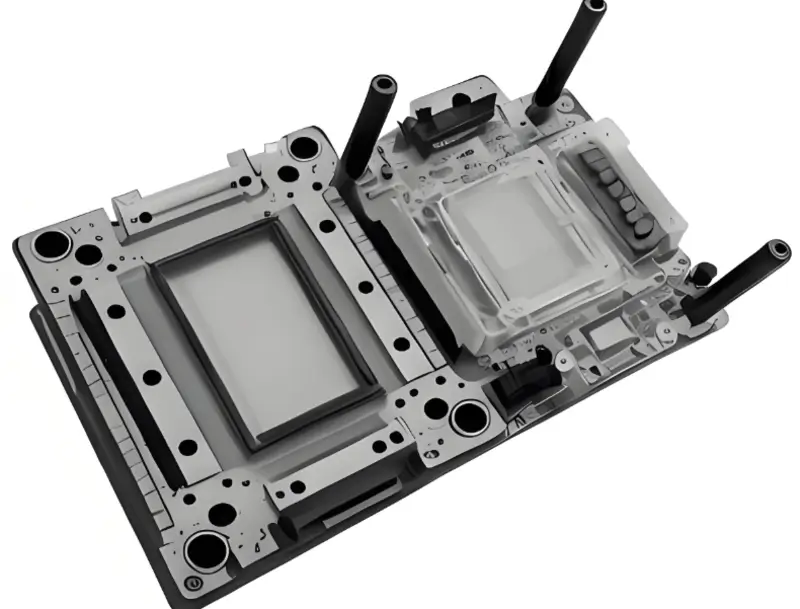

What is the Structure of Injection Molds?

Injection molds consist of several key components, including the cavity, core, runner system, and ejection system, all designed to efficiently shape plastic into desired parts.

The structure of injection molds includes the cavity, core, runners, cooling channels, and ejection system. These parts work together to mold, cool, and eject plastic components quickly and efficiently.

Molding Parts

The parts that give the molding material3 its shape, structure, and size are usually made up of cores (convex molds), concave mold cavities, threaded cores, inserts, etc.

Gating System

It is a channel that guides the molten plastic from the injection machine nozzle to the closed mold cavity. It is usually composed of main channels, branch channels, gates, and cold wells.

Guide Components

To make sure the movable mold and the fixed mold can be aligned accurately when they close, the guide components guide and position them. They’re made up of guide pins and guide sleeves. Some molds also have guide components on the ejector plate to make sure the demolding mechanism moves smoothly and reliably.

Demolding Mechanism

There are many structural forms of the device that realizes the demoulding of plastic parts and casting systems. The most commonly used demoulding mechanisms include ejector pins, ejector tubes, ejector plates, and pneumatic ejectors. They are generally composed of ejector pins, reset rods, slingshots, ejector pin fixing plates, ejector plates (ejector rings), and ejector plate guide pins/guide sleeves.

Mold Temperature Regulation System

To meet the mold temperature requirements of the injection molding process, you need a mold temperature control system with a heating rod to control the mold temperature.

Exhaust System

To allow the gas in the mold cavity to be smoothly discharged, exhaust grooves are often opened on the parting surface of the mold and the corresponding position of the insert sleeve.

Other Structural Parts

Refers to the parts that are designed to meet the requirements of the mold structure (such as: fixed plate, movable/fixed template, support column, support plate and connecting screws, etc.).

Injection molds consist of essential components like cavity and core.True

The cavity and core form the part's shape, while other components ensure smooth molding and ejection.

Injection molds are simple tools with few components.False

Injection molds are complex tools that require multiple components working together to produce high-quality molded parts.

What are the Characteristics of Injection Molds?

Injection molds are crucial tools in the molding process, shaping plastic parts with high precision and repeatability. Their design directly influences production efficiency and part quality.

Injection molds are made from durable materials like steel or aluminum and are designed to create consistent, high-quality plastic parts. They feature cavities that shape the molten plastic and are essential for high-volume manufacturing.

High Production Efficiency

Injection molds utilize mechanical injection molding technology to rapidly and effectively manufacture plastic products of different shapes, with high production efficiency and suitable for high volume production.

High Precision

Because the injection mold uses advanced CNC machining4 technology, the mold structure complexity is low, the machining accuracy is high, and the product size produced is accurate, which is suitable for industries with high requirements for product size accuracy.

Low Structural Complexity

The injection mold has a simple structure, is easy to manufacture and maintain, does not require additional supporting equipment, and can greatly reduce production costs.

Strong Material Plasticity

You can make injection molds with different plastics. They have strong plasticity and can meet the needs of different industries and products.

Long Mold Life

Injection molds are made of high-quality mold steel materials with good wear resistance. They are suitable for mass production and have a long mold life, which can significantly reduce manufacturing costs.

Injection molds are made from steel or aluminum.True

These materials offer durability and high precision, essential for creating complex and high-quality plastic parts in mass production.

All injection molds are suitable for high-volume production.False

While injection molds are designed for mass production, some molds may be better suited for short runs due to their material and design limitations.

What are the Functions of Injection Molds?

Injection molds are essential tools in mass production, shaping materials into specific forms with high precision. They play a crucial role in various industries, from automotive to consumer goods.

Injection molds are used to create complex parts by injecting molten material into a mold cavity. They ensure consistent shapes, enhance efficiency, and reduce waste. Molds are critical in industries such as automotive, electronics, and medical manufacturing.

Shape and Size Control

The main job of the injection mold is to inject the shape and size you want into the plastic. The shape and size of the final product are determined by the shape of the mold cavity. The accuracy and stability of the mold directly affect the quality and consistency of the product.

Therefore, when designing and manufacturing injection molds, you need to consider the requirements and process characteristics of the product to ensure the accuracy and consistency of the final product.

Also, the quality of the mold design and manufacturing directly affects the shape and size of the product. Under the same manufacturing conditions, a good mold will produce a more perfect product.

Also, the mold is the thing that decides the shape in the injection molding process. The chosen melt is injected into the mold under certain conditions, and then it cools down and becomes the shape of the final product.

The mold design not only affects the shape of the product, but also directly affects the quality, life, appearance, and processing efficiency of the product. Therefore, the precision and quality of the mold are very important.

As people\’s requirements for product quality and appearance continue to increase, the manufacturing level of injection molds is also constantly improving, which plays a vital role in the appearance and precision of the product. The precision of the mold will directly affect the precision and surface quality of the injection molded product.

Filling and Compaction of the Injection Cavity

The injection mold does more than just control the shape and size of the product. It also controls how the plastic material gets into the mold and how it gets packed in there. When you’re doing injection molding, the plastic material comes into the mold through the nozzle of the injection machine.

It fills up the whole cavity in the mold and puts pressure on it to make sure the plastic material fills up the mold cavity really well and doesn’t leave any holes or defects. So, when you design and build an injection mold, you have to think about how the plastic material flows and fills up the mold so you can make sure the product comes out right every time.

Temperature Control and Cooling

The injection mold also controls and cools the temperature of the plastic during the injection molding process. The plastic has to be heated and cooled during the injection molding process to melt and solidify.

The injection mold controls the temperature of the mold by having built-in cooling water channels and heaters to control the melting and solidifying of the plastic in the mold. Having a good temperature control and cooling design can improve the surface quality of the product, reduce warpage5 and shrinkage6, and improve production efficiency.

Ejection and Demolding

The injection mold is also responsible for ejecting and demolding during the injection molding process. The ejection mechanism is used to eject the injection molded plastic part from the mold cavity for the next injection molding cycle.

The demolding mechanism is used to completely separate the injection molded plastic part from the mold cavity for subsequent processing and assembly. Therefore, the design of the ejection and demolding mechanism of the injection mold needs to consider the shape and characteristics of the part to ensure the integrity and smooth demolding of the part.

Quality Assurance

Injection molds have high stability and accuracy, and the quality of the products produced is stable and reliable.

Injection molds can achieve high-quality production and manufacturing of products, improve product reliability and durability, so that products can better adapt to market demand.

The design of injection molds has been continuously optimized and adjusted in practice, which can enable products to achieve higher precision and quality requirements in the manufacturing process, thereby meeting customers\’ higher quality requirements.

Molds are one of the most important factors affecting product quality. In the injection molding process, the mold is directly related to the size, appearance, and physical properties of the product. If the mold is not good, it will cause problems such as inaccurate product size, defects, and insufficient strength.

Therefore, in the injection molding process, the precision and quality of the mold are usually the focus of enterprise consideration and an important guarantee for enterprises to improve product quality.

The production technology of injection molds can be adjusted according to the needs of customers and the requirements of products, so as to achieve highly personalized and customized production of products, and help customers get a better product and service experience. So as to better ensure the quality of the product.

As customers have higher and higher requirements for appearance, the molds of injection moulding machine are also constantly upgraded and improved to make the product surface smoother, smoother, and bubble-free, thereby increasing the appearance quality and added value of the product. So that the quality of the product can be well guaranteed.

the injection unit, mould cavity, and injection process collectively determine the quality and efficiency of molding operations .

Improve the Production Efficiency of Products

Good molds not only produce good products, but also improve the production efficiency of injection molding. For example, excellent molds can complete the opening, adsorption, and cooling of molds in the shortest time, thereby improving production efficiency.

With the development of science and technology, injection molds are constantly developing towards multi-function, high performance, high efficiency and intelligence.

The emergence of these new injection molds has effectively improved the production efficiency of enterprises, reduced the production costs and management costs of enterprises, and further improved the economic benefits of enterprises.

When you’re making stuff, injection molds can turn raw materials into the things you need really fast. That means they can help you make stuff faster, make more stuff, and change what you’re making faster when you need to.

Reduce Costs

When you’re developing new products or mass producing products, choosing high-quality molds can help you save money over the life of your product. High-quality molds can be used for a long time, which is good for your bottom line.

High production efficiency: Injection molds are super productive and fast, so you can make a lot of stuff really quickly.

Injection molding technology has the characteristics of high efficiency production, and can produce high-quality products through simple equipment, which improves production efficiency and reduces costs.

Injection molds can achieve automated production, which can reduce labor costs, improve production efficiency, and minimize production costs.

Because plastic product processing has the characteristics of large batches and short production cycles, the efficiency of injection molds is very important for improving the production efficiency of enterprises and reducing production costs. Therefore, improving the processing efficiency of injection molds can effectively reduce costs.

Mold injection can make things out of different stuff, so you can make things out of more than one thing at a time. That way, you can make things that are more complicated and fancier, and you can make things that are different from each other. And it’s cheaper.

Promote the Transformation and Upgrading of the Manufacturing Industry

Injection molds are an advanced production and technical tool. They can improve production efficiency, promote the transformation and upgrading of the manufacturing industry, achieve modern manufacturing, and promote the development and innovation of the industry.

When making injection molds, you can use a bunch of fancy stuff like better design and robots to use less energy and make more stuff. You can also make less pollution and be green, which helps factories get better.

Injection molding technology is a high-end production technology that can help manufacturing companies achieve industrial upgrading and transformation, expand the industrial chain, improve brand influence, promote the transformation and upgrading of the manufacturing industry, and achieve sustainable development.

Injection molds ensure high precision and consistency in mass production.True

Injection molds allow for the consistent production of complex, high-quality parts, which is essential for large-scale manufacturing.

Injection molds are inexpensive and simple to produce.False

The initial cost of designing and creating injection molds can be high, but they provide long-term savings through efficient mass production and reduced material waste.

What are the Uses of Injection Molds?

Injection molds are essential tools in manufacturing, used to create parts from various materials by injecting them into a mold cavity. These molds are used across many industries, from automotive to consumer goods.

Injection molds are used to create precise, high-quality parts for industries such as automotive, electronics, medical, and consumer products. They offer rapid production, high repeatability, and minimal waste, making them crucial for mass manufacturing.

Daily Mecessities

Injection molds are widely used in the production of everyday items, like plastic cups, plastic chairs, plastic tableware, and so on. These products are loved by consumers because they are lightweight, easy to carry, and inexpensive.

Electrical Products

Injection molds also play an important role in the manufacturing of electrical products like chargers, hair dryers, digital cameras, etc. After injection molding, these products have good durability and insulation properties.

Automotive Parts

Injection molds are also used to make automotive parts, like car handles, dashboards, headlight covers, and so on. These manufacturing plastic parts need to be made with high precision and high complexity, so you need a high-precision injection mold to make them.

Medical Devices

You also need injection molds to make medical devices like infusion sets, syringes, blood collectors, etc. These things have to be super safe and clean, and the standards for how precise and well-made the molds are have to be really high too.

Industrial Machinery and Equipment

Injection molds are also widely used in the production process of industrial machinery and equipment. For example, the production of robot parts, vertical machining center parts, high-speed milling machine parts, etc. These products require high-precision injection molds to produce.

Injection molds are cost-effective for high-volume production.True

Injection molds allow for quick, repetitive manufacturing, reducing per-unit costs as production volume increases.

Injection molds are only used for plastic parts.False

Injection molds can be used for various materials, including metals, ceramics, and even some food products, depending on the process and material requirements.

Conclusion

So, in conclusion, injection molds are important in the plastic injection molding process7. They determine the shape and size of the final product, and they affect the quality and efficiency of the product.

If you design and make the injection molds right, you can make the products more consistent and stable, reduce the cost of making them, make them faster, and make them better. That way, you can make your customers happy and beat your competition.

So, the research and development and application of injection molds are super important and play a huge role in promoting the development and progress of the injection molding industry.

-

Learn about Injection Molding Machine Screw Function : The basic function of either a injection molding or extrusion screw is to simply convey the material to the mold or die in an even mixture of resin …… ↩

-

Learn about How do you calculate injection pressure?Injection pressure is the pressure of the melt acting on the head of the screw during injection molding. ↩

-

Learn about What are the Commonly Used Injection Molding Materials? The most commonly used injection molding materials include thermoplastics like ABS, polypropylene (PP), and polycarbonate (PC) ….. ↩

-

Learn about What Is CNC Machining?Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. ↩

-

Learn about Warpage : Warpage refers to the distortion or deformation of a material . ↩

-

Learn about Injection moulding – how to avoid plastic shrinkage :Plastic shrinkage is an unfortunate consequence of the injection moulding process. ↩

-

Learn about Tips for optimizing the injection molding process :optimizing the whole injection molding production process is paramount for companies seeking to maintain a competitive edge. ↩