Introduction: When we talk about best practices for plastic injection molded parts, there are some things you just can’t avoid. At the top of that list is usually the injection draft angle. Every injection molding design is designed for manufacturability. So, you have to think about every step of the process.

Even if your part is molded correctly in the mold, you can run into problems when you try to get it out of the mold. This can cause defects in your part that you don’t want. Draft angles will help you avoid a lot of these problems. In this article, we’re going to give you a complete guide to designing draft angles for the structural design of plastic parts.

What is the Meaning of Draft Angle?

The draft angle, as the name suggests, is the angle designed for the mold. To be precise, it is the draft angle of the mold surface parallel to the mold ejection direction, also known as the draft angle.

Who Designs the Draft Angle?

Since the draft angle is ultimately reflected on the mold, there will be a dispute among designers of the draft angle, that is, whether the draft angle should be designed by the structural engineer or the mold engineer. There are currently two mainstream practices for this: the structural engineer needs to perfect the draft of all surfaces during the part design stage (except for individual structures that cannot be determined and need to be evaluated by the mold engineer).

The structural engineer is only responsible for drafting the appearance surface and key assembly surface, and other insignificant surfaces are left to the mold design stage for the mold engineer to draft based on experience.

Types of Draft Angles

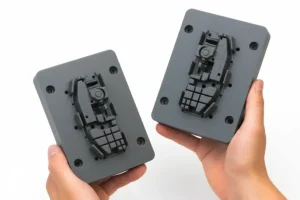

The draft angle is divided into the front mold surface draft angle and the rear mold surface draft angle. They are mainly distinguished by the parting surface. The parting surface divides the mold core into the front mold and the rear mold.

The draft angle that needs to be designed on the surface parallel to the ejection direction of the front mold is called the front mold surface draft angle, and vice versa, it is called the rear mold surface draft angle. In addition, if the mold has side core pulling (bevel top and slider), it is called the bevel top surface draft angle and the slider surface draft angle, and its draft direction is based on the direction of slider movement.

The draft direction is usually based on the parting surface for drafting, making sure that the larger end after drafting is close to the parting surface, otherwise it can’t be demolded smoothly.

Why do We Need to Design a Draft Angle?

The draft angle is a design feature. In theory, if it is not required for modeling, the product structure does not need to design a draft angle. However, due to the limitations of the molding process, such as injection molding, the plastic product needs to be taken out of the mold after molding and cooling. If the draft angle is not designed, the plastic part will be difficult to remove from the mold.

Recall that you must have encountered a situation where it is difficult to separate the stacked plastic stools. That is already a stool with a designed slope, not to mention that the plastic parts without a draft angle need to be taken out of the mold.

Why is It Difficult to Take the Plastic Parts Out of the Mold Without a Draft Angle?

In injection molding, the molten resin flows into the closed mold and fills the cavity formed between the front mold and the back mold. Since thermoplastics shrink when cooling, the plastic tends to shrink toward the mold core. The shrunk plastic parts will be tightly adsorbed on the mold core. In addition, some plastics may be pulled away from the mold cavity wall (microscopic level), but most of them are still in contact with the cavity wall.

When the mold opens, the plastic part will experience a friction resistance (static friction) in the opposite direction of the plastic part leaving the mold, whether the outer surface of the plastic part contacts the cavity wall or the inner surface of the plastic part contacts the core. From the friction formula: f=μ×Fn, it can be seen that the magnitude of the friction force is related to the roughness (μ) and shrinkage stress (Fn) of the contact surface; the shrinkage stress (Fn) is related to the draft angle.

After designing the draft angle, f=μ×Fn×cosα, the friction force f in the direction of ejection decreases as the draft angle α increases. In general, the draft angle is not very large. Obviously, the draft angle is limited to reduce the static friction.

The main function of the draft angle is that once the plastic part is separated from the mold, it will separate and no longer form contact with the mold, and the friction will be eliminated; without the design of the draft angle, the plastic part will turn into sliding friction after being separated from the mold.

At the same time, for the high-gloss appearance surface, the front mold cavity may also form a vacuum, and the vacuum suction will make it difficult for the plastic part to be completely separated from the front mold. The worst result is that the front mold is stuck and the structure of the rear mold of the plastic part is pulled and deformed.

Benefits of Draft Angle

Sometimes, the draft angle can cause a conflict of interest. For injection molding manufacturers, they focus on molding and want a bigger draft angle; for mold processing manufacturers, they find it difficult to machine angles on all cavity and core surfaces.

Originally, simple features only need simple processing equipment and lower processing costs, but after demolding, CNC or even EDM is needed; for product designers, the draft angle may complicate the part design, and the appearance shape will also change because of the draft angle.

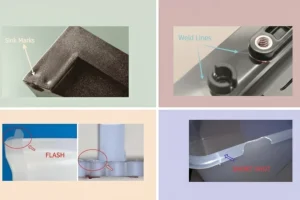

But no matter which side you’re on, it’s important to make sure your molded parts meet the quality standards you need. That’s critical. If you don’t have a draft angle, you’re going to increase the chances of having injection molding problems. That could unnecessarily increase your production costs and your lead time. In addition to the convenience of getting parts out of the mold, here are some other benefits of having a draft angle.

Prevent damage to the part surface from friction during ejection; Ensure uniformity and integrity of other surface textures and finishes; Minimize part deformation from unsmooth ejection; Reduce wear on molded parts and the chance of damaging the mold; Shorten overall cooling time by eliminating or reducing the need for complex ejection settings; Directly and indirectly reduce overall production costs.

Principles of Draft Angle Design

Ensure Ejection Requirements

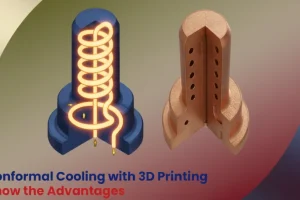

Once the mold is opened, the plastic part needs to stay on the side of the rear mold to help eject the plastic part from the mold. This needs to be done in two steps: First, the outer surface of the plastic part is separated from the front mold cavity wall. In this step, the mold generally doesn’t have any extra things to help separate it, so the friction between the outer surface of the plastic part and the cavity wall is as small as possible.

Then, the inner surface of the plastic part is separated from the core wall of the rear mold. In this step, the mold generally has something extra to help separate it, like an ejector pin, an inclined ejector, or a push plate. The friction between the inner surface of the plastic part and the core should be greater than the friction between the outer surface of the plastic part and the cavity wall to some extent, so the plastic part stays on the rear mold side when the mold is opened.

As we can see from the above, since the plastic has a tendency to shrink towards the mold core (i.e., the shrinkage stress is large), when the roughness and draft angle are constant, the friction between the inner surface of the plastic part and the core will be greater than the friction between the outer surface of the plastic part and the cavity wall.

At the same time, the ejection mechanism of the mold is usually on the rear mold side. Therefore, in general, the core is designed in the rear mold and the cavity is designed in the front mold, that is, the complex side of the plastic part is designed in the rear mold, and the relatively simple side (appearance surface) is designed in the front mold.

But there are exceptions. For example, sometimes the inside of a part is the outside, and you can’t have ejector marks. In that case, you put the core in the front mold and the cavity in the back mold. To keep the front mold from sticking, you need an ejector helper on the front mold, like this.

Some parts look the same from top to bottom and have no obvious appearance surface, such as the part in the figure below. It is impossible to quickly determine the front and rear molds of the parts. For such parts, if there is no requirement, the front and rear molds can be placed anywhere. In order to prevent the front mold from sticking.

when designing the mold, as long as the draft angle of the back mold is as small as possible and the draft angle of the front mold is as large as possible (within the tolerance range of the product size), the part can stay in the movable mold after the mold is opened, so that the ejector auxiliary mechanism can be avoided in the front mold.

For the structure below with adjustment space, the core glue position is changed from half of the original front and rear molds to 1/3 of the front mold and 2/3 of the rear mold, which can reduce the risk of sticking to the front mold.

Design of Draft Angle

There is no unified standard for the range of draft angle, and the theoretical calculation is very difficult, because the mathematical model of friction is difficult to establish, and different injection molding parameters will also affect the final result. Some reference values may be obtained through simulation calculation, but it is time-consuming and labor-intensive.

Generally, mold factories do not have the strength and time to do it. It is more based on experience. As a structural engineer, you need to understand this knowledge so that you can take the draft angle into account for certain key structures in the structural design stage, reduce the number of subsequent feedback modifications by mold engineers, and avoid unnecessary trouble.

Determinants of the Draft Angle

Molding Material Characteristics

Hard plastics have a bigger draft angle than soft plastics, and soft plastics can even have undercuts.

Shrinkage Rate

Because the plastic with a big shrinkage rate has a bigger clamping force on the core, the plastic with a big shrinkage rate should have a bigger draft angle than the plastic with a small shrinkage rate.

Friction Coefficient

For some materials with a low friction coefficient, such as PA and POM, the draft angle can be smaller than other ordinary plastics. The bigger the friction coefficient of the product surface, the bigger the draft angle. For example, the sun-textured surface requires a big draft angle.

Wall Thickness

When the wall thickness increases, the force of the plastic wrapping the core is greater, and the draft angle should also be larger.

Geometric Shape

For plastic parts with more complex shapes or more molding holes, a larger draft angle is required, otherwise more ejectors need to be arranged, and the ejector arrangement needs to be symmetrical and uniform to prevent uneven ejection force from causing part warping and deformation.

Transparent Parts

The draft angle of parts with optical requirements should be large.

Specific Range of Draft Angle

The geometric relationship between the draft angle and the draft surface height is as follows: tanθ=X/H;

where θ is the draft angle, H is the draft surface height, and X is the reduced wall thickness (or tilt deviation).

In theory, the larger the draft angle, the easier it is to demold, especially for draft surfaces with higher height (depth) and larger area. This is because the clamping force of this face on the core or cavity is greater, and a larger slope must be designed to facilitate demolding when the ejection force of the injection molding machine remains unchanged.

But, according to the geometric relationship above, when H is constant, the larger θ is, the larger X is.

For the appearance surface, the larger X is, the more the appearance surface changes, even to the point of deviating from the ID intention, and the appearance size deviation will be large. Therefore, if the ID allows, the larger the appearance surface draft, the better. If the ID does not allow,

For high-gloss surface, the draft angle ≥1°, to prevent the risk of scratches, try to take the largest value possible;

For a textured surface, the draft angle should be at least 3° (depending on the type and depth of the texture, typically you need 1 to 1.5° of draft for every 0.001mm of depth, but you should use the draft angle data provided by the texture company as a guide).

When it comes to the bone surface, the bigger the X, the smaller the top width C of the bone, and the harder it is to do injection molding. So, the bone should be designed to be as short as possible, and the draft angle can be bigger. If you can’t avoid it, at least make sure that the value of X is generally ≥0.2, and the top width C is not less than 0.6;

When it comes to the screw column, the inner hole of the screw column is a kind of structural feature with dimensional accuracy requirements. For this kind of structural feature, in order to ensure the tolerance range, the draft angle will be very small or even no draft angle. The mold structure here requires very small roughness or even polishing, and the ejector pin needs to be reasonably designed nearby.

If you have a sleeve ejector, you don’t need to draft the screw hole. If you have a regular ejector, you need to draft the screw hole. The height of the screw hole should not be too high, and the angle should be between 0.5° and 1.0°. The draft should be half of the screw engagement depth L, because this will give you good screw engagement. Don’t make the top of the hole bigger and the bottom of the hole smaller, because then the screw will be loose at the top and tight at the bottom, and you’ll have high stress.

For other internal surfaces, the draft angle is 1° as the median value. The specific value needs to be determined according to the height and roughness of the draft surface. At the same time, pay attention to the change in glue thickness after drafting to avoid molding defects.

Conclusion

I’m not going to talk about draft angles because they look good. I’m going to talk about draft angles because they’re important. They’re important because they make your parts easier to make and they make your parts better. If you don’t put draft angles on your parts, you’re going to have a lot of parts that get rejected.

It can also cause mold damage. It is best to always be aware of the best practices of injection molding. One of them is to incorporate draft angles in injection molding.

At the injection molding industry, we are injection molding experts and are ready to share our expertise with you. Our engineers have a deep understanding of injection molding best practices and incorporate them into our services. Our engineers can fully evaluate your design and provide recommendations. We provide DfM to ensure that you get the best results from your part design.

We offer a wide range of manufacturing services, including injection molding. If you’re not sure if your draft angle is sufficient for your needs, we can have a design discussion. We also offer a general part inspection to make sure your parts are ready for molding. All of these services are offered at a competitive price.