Injection molding materials are key to producing high-quality parts with desired properties. Commonly used materials include thermoplastics, thermosets, and elastomers, each offering unique benefits depending on the application.

The most commonly used injection molding materials are thermoplastics like ABS, polypropylene, and polycarbonate, thermosets such as epoxy, and elastomers like silicone. They provide various benefits in automotive, medical, and consumer goods manufacturing, including durability, flexibility, and heat resistance.

Choosing the right material is crucial for achieving product performance and cost-effectiveness. Dive deeper into each material’s properties to determine the best fit for your specific manufacturing needs.

Thermoplastics are the most commonly used injection molding materials.True

Thermoplastics like ABS, polypropylene, and polystyrene are popular due to their excellent flow properties, ease of molding, and recyclability.

Thermoplastics are always stronger than thermosets.False

Thermoplastics are flexible and can be molded multiple times, while thermosets, once cured, offer superior strength and heat resistance for specific applications.

What is Acrylic (PMMA)?

Acrylic (PMMA) is a versatile thermoplastic with excellent transparency, weather resistance, and impact strength. It’s widely used in various industries, including automotive, signage, and medical applications.

Acrylic (PMMA) is a clear, durable plastic known for its optical clarity and weather resistance. It’s used in products like windows, displays, and lighting covers. Its key benefits include high transparency and UV resistance, making it ideal for outdoor and decorative applications.

Definition

Acrylic, also known as PMMA, is a thermoplastic1 plastic materials with good mechanical strength, light weight, and a clear, transparent appearance. Although it has no ductility, it has good resistance to chipping.

It is an important plastic polymer material that was developed earlier. It has good transparency, chemical stability and weather resistance, easy dyeing, easy processing, and beautiful appearance.

It is widely used in the construction industry. Organic glass products can generally be divided into cast plates, extruded plates, and molded materials.

It has crystal-like transparency, light transmittance of over 92%, soft light, clear vision, and acrylic colored with dyes has a good color development effect. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

Acrylic sheet is easy to process and can be processed by thermoforming or machining. Transparent acrylic sheet has a light transmittance similar to glass, but the density is only half of glass.

Plus, it’s not as fragile as glass, and even if it does break, it won’t shatter into sharp pieces like glass. Acrylic sheet is almost as tough as aluminum, with good stability and resistance to all sorts of chemicals.

Acrylic sheet has good printability and sprayability. Using the right printing and spraying processes can give acrylic products a great surface decoration effect. Flame resistance: It doesn’t self-ignite but it’s a flammable product and doesn’t have self-extinguishing properties.

Typical Application Range

PMMA has the advantages of being light, cheap, and easy to shape. It can be shaped by casting, injection molding, machining, thermoforming, and other methods. Injection molding, in particular, can be used to make a lot of things, with a simple process and low cost. So it is used more and more widely. It is used in instrument parts, car lights, optical lenses, transparent pipes, and so on.

Acrylic is stronger than glass.False

While acrylic is more impact-resistant than glass, it is not stronger in terms of tensile strength, as it is more prone to scratching.

Acrylic is UV resistant.True

Acrylic has inherent UV resistance, which prevents it from yellowing or degrading under sunlight exposure, making it ideal for outdoor applications.

What is Acrylonitrile-Butadiene-Styrene (ABS)?

Acrylonitrile-Butadiene-Styrene (ABS) is a popular thermoplastic polymer known for its toughness, impact resistance, and ease of molding. It’s widely used in automotive, consumer electronics, and household products.

ABS is a durable, versatile plastic combining acrylonitrile for chemical resistance, butadiene for impact strength, and styrene for ease of processing. It’s commonly used in toys, automotive parts, and appliances due to its strength and formability.

Definition

ABS plastic is a terpolymer of three monomers: acrylonitrile (A), butadiene (B), and styrene (S). It is light ivory, opaque, non-toxic, and odorless. The raw materials are easily available, the comprehensive performance is good, the price is cheap, and the application is wide, so ABS is one of the most widely used engineering plastics , low melting point .

The Characteristics of ABS Plastic Are as Follows

It has high mechanical strength, strong impact resistance, and good creep resistance; it has the characteristics of hardness, toughness, rigidity, etc.; the surface of ABS plastic parts can be electroplated; ABS can be blended with other plastics and rubbers to improve its performance, such as (ABS + PC). It has good strength and toughness, impact resistance, and chemical resistance to acids, alkalis, and oils.

It has good strength and toughness, impact resistance, and chemical resistance to acids, alkalis, and oils. It is completely opaque and can be injection molded into a variety of colors. Most importantly, it is very cheap compared to other plastic injection molding materials in this list.

But it doesn’t work well in direct sunlight or humid environments. So, avoid those applications.

Typical Application Range

ABS is perfect for industrial applications like car parts and high-strength sports gear, cars, TVs, fridges, washing machines, air conditioners, and other electrical stuff.

ABS is impact-resistant and durable.True

ABS offers high impact resistance and toughness, making it ideal for products requiring strength and durability, such as automotive parts and consumer electronics.

ABS is suitable for all types of injection molding.False

ABS may not be suitable for every injection molding process, as its flow properties require specific molding techniques for optimal results.

What is Nylon Polyamide (PA)?

Nylon (PA) is a versatile synthetic polymer used in various applications due to its durability, strength, and resistance to wear and chemicals.

Nylon Polyamide (PA) is a strong, durable thermoplastic used in textiles, automotive parts, and electrical components. It offers excellent wear resistance, low friction, and high-temperature stability, making it ideal for demanding environments.

Definition

Nylon is a great material. It’s tough, heat resistant, and has good friction and wear properties. It’s a natural material and it’s also made synthetically. The synthetic kind is great for injection molding. It also has vibration damping properties, so it’s good for making noise dampeners.

The Characteristics of Nylon are As Follows

Nylon has high crystallinity, which means it has high mechanical strength and good toughness. It also has high tensile and compressive strength. It has outstanding fatigue resistance, wear resistance, corrosion resistance, heat resistance, and non-toxicity. It also has excellent electrical properties. However, it has poor light resistance, it absorbs water easily, and it is not acid-resistant.

Typical Application Range

Because it’s strong and stiff, people use it to make things that hold stuff up. Because it’s slippery, people use it to make things that slide.Nylon things include gears, bearings, guitar strings, raincoats, and ropes.

Nylon Polyamide is ideal for automotive parts.True

Nylon PA’s durability, high temperature resistance, and wear resistance make it perfect for automotive components like gears, bearings, and under-the-hood parts.

Nylon PA is not suitable for high-impact applications.False

Nylon PA can withstand moderate impact, but when combined with other materials, it can be used in high-impact environments.

What is Polycarbonate ( PC) ?

Polycarbonate (PC) is a versatile, durable plastic known for its transparency and impact resistance. It’s widely used in industries like automotive, electronics, and medical devices due to its strength and optical clarity.

Polycarbonate (PC) is a strong, transparent plastic known for high impact resistance, optical clarity, and thermal stability. It’s used in eyewear lenses, automotive parts, and medical devices due to its toughness and transparency.

Definition

PC plastic is a hard material, commonly known as bulletproof glass. It is non-toxic, tasteless, odorless, and transparent. It is flammable, but it can self-extinguish after being removed from the fire.

Polycarbonate Characteristics

It’s super tough and hard. It has the best impact strength of all thermoplastic materials; excellent creep resistance, good dimensional stability, high molding precision; good heat resistance (120 degrees);

The downsides are low fatigue strength, high internal stress, easy to crack; the wear resistance of plastic parts is poor. PC has excellent toughness, anti-fragmentation and impact resistance. It has a transparent appearance. In addition, it has the ideal quality of maintaining its mechanical properties and appearance over a wide temperature range. Therefore, it works well in high temperature environments.

Typical Application Range

PC is super clear, usually clearer than glass. That’s why it’s a popular material for making helmet visors, machine guards, and goggles. But PC is bad for you, especially your baby-making parts. So you can’t use it for stuff like food and drink.

Other uses include Stuff like computer parts, plugs, and all that. Also, things like kitchen gadgets, like food processors and mini fridges. And then there’s car stuff, like headlights and dashboards.

Polycarbonate is more durable than glass.True

Polycarbonate is significantly more impact-resistant than glass, making it ideal for applications where strength and safety are crucial.

Polycarbonate is the same as acrylic in all aspects.False

Polycarbonate is more durable and impact-resistant than acrylic, but acrylic offers better clarity and is more scratch-resistant.

What is Polyoxymethylene (POM) ?

Polyoxymethylene (POM), also known as acetal, is a high-performance engineering plastic widely used in precision parts for industries like automotive, electronics, and medical devices due to its excellent mechanical properties.

Polyoxymethylene (POM) is a strong, durable thermoplastic with high stiffness, low friction, and resistance to wear and chemicals. It is commonly used in gears, bearings, and other precision components due to its excellent dimensional stability.

Definition

POM, also known as acetal, is a hard material and an engineering plastic. It has a crystalline structure with excellent mechanical properties, high elastic modulus, high rigidity and surface hardness, and is known as the rival of metal.

POM is great for things that need to be really precise. It’s stiff and rigid, so it doesn’t change shape much. It’s also slippery and slides well, so it’s good for things that rub together a lot. It also works well when it’s really cold.

The Characteristics of Polyoxymethylene Are As Follows

It has a low coefficient of friction, great wear resistance, and self-lubrication, second only to nylon, but cheaper than nylon. Good solvent resistance, especially organic solvents, but not resistant to strong acids, strong alkalis, and oxidants; good dimensional stability, can be used to manufacture precision parts; large molding shrinkage, poor thermal stability, easy to decompose when heated.

Typical Application Range

POM has a very low friction coefficient and good dimensional stability, and is especially suitable for making gears and bearings. Because it also has high temperature resistance, it is also used for pipeline devices (pipe valves, pump housings), lawn equipment, etc.

It is better to use plastic injection molding for hard automotive parts (like handles and switches). It is also used for kitchen knives, gears, furniture, and ball bearings.

Polyoxymethylene (POM) is highly resistant to wear.True

POM has exceptional wear resistance, making it ideal for use in moving parts like gears and bearings.

Polyoxymethylene (POM) is unsuitable for high-temperature environments.False

While POM performs well at room temperature, it can also handle moderately high temperatures, making it suitable for a range of applications beyond low-temperature uses.

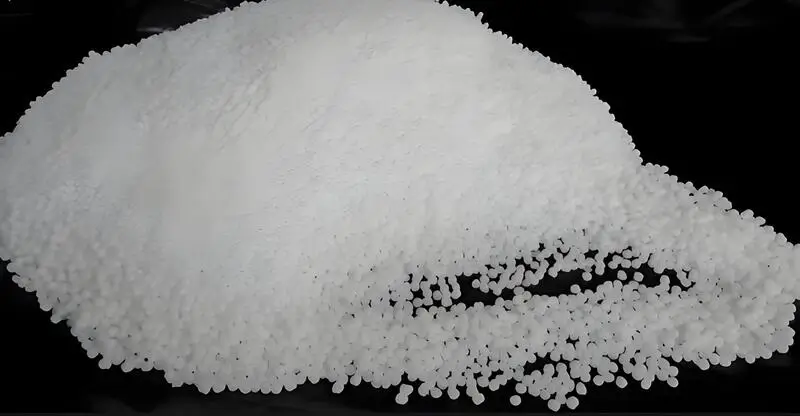

What is Polypropylene (PP)?

Polypropylene (PP) is a versatile plastic used in various applications, known for its durability, chemical resistance, and cost-effectiveness in manufacturing.

Polypropylene (PP) is a thermoplastic polymer used widely in packaging, automotive, and medical products. It is known for its resistance to heat, chemicals, and fatigue, offering versatility and recyclability.

Definition

PP soft glue, also known as Baizhe soft glue, is a colorless, transparent or glossy granular material, and is a crystalline plastic. PP is everywhere around us, especially in our kitchen cabinets in the form of food containers. It is one of the most common plastic injection molding materials approved for use by the FDA , good chemical resistance .

The Characteristics of Polypropylene Are As Follows

Good fluidity and excellent molding performance; excellent heat resistance, can be boiled and sterilized at 100 degrees Celsius; high yield strength; good electrical properties; poor fire safety; poor weather resistance, sensitive to oxygen, and easily aged by ultraviolet rays.

It’s tough, it can take the heat, it can take the chemicals, and it can be recycled over and over again. That makes it easy to work with. But it has a high coefficient of thermal expansion. That means it doesn’t work well at high temperatures. It also makes it hard to control when you’re trying to mold it. After you mold it, it breaks down in ultraviolet (UV) light and it catches on fire.

Typical Application Range

Some of the things it’s used for are food containers, carpets, toys, and household appliances. The automotive industry (they mainly use PP with metal additives: fenders, vents, fans, etc.), appliances (dishwasher door liners, dryer vents, washing machine frames and covers, refrigerator door liners, etc.), everyday consumer goods (lawn and garden equipment like lawn mowers and sprinklers, etc.) , medical devices .

Polypropylene (PP) is highly resistant to chemicals.True

PP resists many chemicals, making it ideal for use in containers, automotive parts, and medical devices.

Polypropylene (PP) is the most expensive plastic option.False

PP is one of the more affordable plastics, especially compared to materials like polycarbonate or PEEK, offering excellent performance at a lower cost.

What is Polystyrene (PS) ?

Polystyrene (PS) is a versatile and widely used plastic known for its ease of processing, clarity, and low cost. It finds applications in various products, from packaging to consumer goods.

Polystyrene (PS) is a synthetic polymer used in packaging, insulation, and disposable products. It can be rigid or foam, offering excellent transparency and ease of molding. PS is cost-effective but lacks durability compared to other plastics.

Definition

PS, also known as hard glue, is a colorless, transparent, shiny granular substance. PS is one of the few brittle injection molding materials , high melting point .

The Characteristics of Polystyrene Are As Follows

Good optical properties; excellent electrical properties; easy molding and processing; good coloring performance; the biggest disadvantage is brittleness; low heat resistance temperature (maximum use temperature 60~80 degrees Celsius); poor acid resistance.

Typical Application Range

PS is used to make toys, electrical appliances, containers, etc. It also has a special place in the medical device industry because it does not degrade due to gamma radiation, which is the main method of sterilizing medical equipment.

Therefore, equipment such as culture dishes and culture kits are all injection molded with PS.Product packaging, household goods (tableware, trays, etc.), electrical (transparent containers, light diffusers, insulating films, etc.).

Polystyrene is the most durable plastic.False

While polystyrene is cost-effective, it is not as durable or impact-resistant as other plastics like ABS or polycarbonate.

Polystyrene is easy to mold and shape.True

Polystyrene is a low-cost, easy-to-mold plastic that is used in a variety of industries for products like packaging and disposable cutlery.

What is Polyethylene (PE) ?

Polyethylene (PE) is a widely used plastic, known for its durability, flexibility, and resistance to chemicals. It is commonly found in products like plastic bags, containers, and pipes.

Polyethylene (PE) is a versatile, low-cost plastic used in packaging, containers, and household goods. It is valued for its toughness, resistance to moisture, and low friction properties, making it ideal for everyday applications.

Definition

PE is one of the most commonly used plastics in everyday life. It is a white waxy solid, slightly waxy, odorless, tasteless, and non-toxic. Except for the film, other products are opaque because PE has a high degree of crystallinity.

PE is divided into three categories with different densities: high-density polyethylene (HDPE), low-density polyethylene (LDPE0).

The Characteristics of Polyethylene Are As Follows

Resistant to low temperature or cold, corrosion-resistant (not resistant to nitric acid), insoluble in general solvents at room temperature; low water absorption, less than 0.01%, excellent electrical insulation . Yansir has high ductility and impact strength, and low friction. It has a tendency to deform under continuous force, but this can be reduced by adding short fibers. It is not easily penetrated by water, but it allows air to pass through, making it suitable for moisture-proof packaging.

Non-polar surface, hard to bond and print; not UV-resistant and poor weather resistance, will become brittle in the sun; large shrinkage, easy to shrink and deform (shrinkage: 1.5~3.0%).

PE grades are usually ductile, have good impact strength and creep resistance (can withstand mechanical loads for a long time without deformation). They are also resistant to chemical reactions. HDPE is stronger and harder.

Typical Application Range

It can be used to mold things like kettles, bathtubs, and pipes. On the other hand, LDPE is more flexible. It is a great packaging plastic material with top products worth billions of dollars in the packaging industry (shopping bags, foils, films). And it is widely used in the production of plastic bags, plastic films, wire and cable coverings and coatings, etc.

Polyethylene is a strong and flexible material.True

PE is known for its durability and flexibility, making it suitable for a wide range of applications, from packaging to construction.

All polyethylene types are the same.False

Polyethylene comes in various forms, such as HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene), each offering distinct properties suited for different uses.

What is Thermoplastic Elastomer (TPE) ?

Thermoplastic Elastomers (TPE) are a class of polymers combining the properties of rubber and plastic. They are versatile, durable, and commonly used in injection molding for flexible products.

Thermoplastic Elastomers (TPE) are flexible, durable polymers that can be melted and reformed multiple times. TPE is commonly used in automotive, medical, and consumer products due to its flexibility, durability, and recyclability.

Definition

Thermoplastic elastomer, known as TPE or TPR, is short for Thermoplastic rubber. It is a type of elastomer that has the elasticity of rubber at room temperature and can be plasticized and molded at high temperatures.

The Characteristics of Thermoplastic Are As Follows

Its products not only have the excellent properties of high elasticity, aging resistance, and oil resistance of traditional cross-linked vulcanized rubber, but also have the characteristics of convenient processing and wide processing methods of ordinary plastics.

It can be made by injection molding , extrusion, blow molding and other processing methods, and 100% of the water outlet corners can be directly reused after crushing. It not only simplifies the processing process but also reduces the processing cost.

So, TPE/TPR materials are the latest materials to replace traditional rubber. They are environmentally friendly, non-toxic, comfortable to the touch, and exquisite in appearance, making the products more creative.

It can be processed by general thermoplastic plastic molding machines, such as injection molding, extrusion molding, blow molding, compression molding, transfer molding, etc.You can vulcanize it with a rubber injection molding machine, and the time can be shortened from 20 minutes to less than 1 minute. You can vulcanize it with an extruder, and it extrudes fast and vulcanizes quickly.

TPE is both flexible and recyclable.True

TPE's unique properties allow it to be molded into flexible parts that can also be recycled, offering both durability and environmental benefits.

TPE is always more expensive than traditional rubber.False

While TPE can be more expensive than traditional rubber, it offers advantages in processing and performance that may justify its cost in many applications.

What is Thermoplastic Polyurethane (TPU) ?

Thermoplastic Polyurethane (TPU) is a versatile elastomer known for its flexibility, durability, and resistance to wear. It is used in various applications, from automotive parts to medical devices.

TPU is a highly flexible, durable, and abrasion-resistant material used in industries like automotive, electronics, and medical devices. It offers excellent elasticity, transparency, and chemical resistance, making it ideal for demanding applications.

Definition

TPU, short for thermoplastic polyurethane elastomer (or thermoplastic polyurethane rubber), is a linear polymer of the (AB)n type. A stands for a high molecular weight (1000~6000) polyester or polyether, B stands for a diol with 2~12 straight-chain carbon atoms, and the chemical structure between the AB segments is diisocyanate.

Thermoplastic Polyurethane Properties Are As Follows

Polyurethane thermoplastic elastomers are known for their great wear resistance, great ozone resistance, high hardness, high strength, good elasticity, low temperature resistance, good oil resistance, chemical resistance and environmental resistance, and the hydrolysis stability of polyether esters in humid environments is much better than that of polyesters.

TPU is another rubber-plastic blend2 whose polyurethane component has some really great qualities. It’s very hard and has good compressive strength, wear resistance, and chemical resistance. Plus, these properties don’t change much at extreme temperatures.

Typical Application Range

Thermoplastic polyurethane elastomer, with its excellent performance and wide application, has become one of the important thermoplastic elastomer materials. Its molecules are basically linear, with no or little chemical crosslinking.

The linear polyurethane molecular chains are physically crosslinked by hydrogen bonds. These hydrogen bonds enhance their morphology, giving them many excellent properties, such as high modulus, high strength, excellent wear resistance, chemical resistance, hydrolysis resistance, high and low temperature resistance, and mildew resistance.

These good properties make TPU widely used in many fields such as footwear, cables, clothing, automobiles, medicine and health, pipes, films and sheets.

TPU is flexible and resistant to wear.True

TPU's molecular structure allows it to retain flexibility and resist abrasion, making it ideal for tough environments.

TPU is the most cost-effective material for every application.False

While TPU is highly durable, its cost can vary depending on the application, and sometimes other materials may offer a more cost-effective solution.

Conclusion

In short, there are many types of materials that can be used for injection molding3 , and manufacturers can precisely customize the selection according to the needs of each application.

From the flexibility of PE and the toughness of ABS to the transparency of PC and the elasticity of TPE, each material brings unique characteristics to the process. Understanding these material properties, you can choose the injection molding material that best suits your application.

-

Learn about Thermoplastics : Some of the most common types of thermoplastics are polypropylene, polyethylene, polyvinyl chloride, polystyrene, polyethylene terephthalate and polycarbonate. ↩

-

Learn about Rubber–Plastic Blends: Rubber-plastic blends provide a way of attaining useful properties intermediate between the parents by combining the stiffness of plastics with the resilience of rubbers. ↩

-

Learn about What are the Commonly Used Injection Molding Materials? The most commonly used injection molding materials include thermoplastics like ABS, polypropylene (PP), and polycarbonate (PC), as well as thermosetting plastics such as epoxy and phenolic resins. ↩