Cold runner systems play a pivotal role in injection molding, offering a cost-effective solution for producing high-quality parts with minimal waste.

Cold runner systems operate by allowing the plastic to cool in the runner channels, which can be removed from the finished part, making them ideal for low-volume production. They are commonly used in applications where part weight and precision are critical. Key advantages include reduced upfront costs and easier maintenance compared to hot runners.

This overview emphasizes the benefits of cold runner systems, but a deeper understanding of their design and operational principles is vital for optimizing your injection molding processes. Continue reading to learn how to effectively integrate cold runner systems into your manufacturing workflow.

Cold runner systems are ideal for high-volume production.False

Cold runners are better suited for low to medium volume production, as they can lead to more waste and longer cycle times compared to hot runners in high-volume scenarios.

Cold runner systems are easier to maintain than hot runners.True

Cold runner systems have fewer components and are generally simpler in design, making maintenance and repairs less complex and more cost-effective.

What is the Cold Runner System in Injection Molding?

Cold runners create a channel for molten plastic that cools before reaching the mold cavity, leading to efficient filling and minimal material waste. They are ideal for small to medium production runs and are commonly used in consumer products and packaging. Key advantages include lower setup costs and simpler maintenance.

Definition of Cold Runner Systems

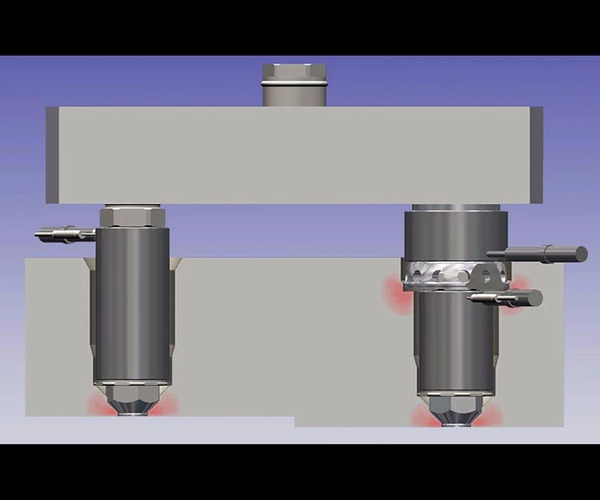

In contrast to hot runner1system, cold runners stay at room temperature and their job is to carry liquid plastic from the machine’s nozzle (where it is first heated to melting point) into a mold cavity where the material cools down again so that it can be ejected as a finished product once the cycle time has elapsed.

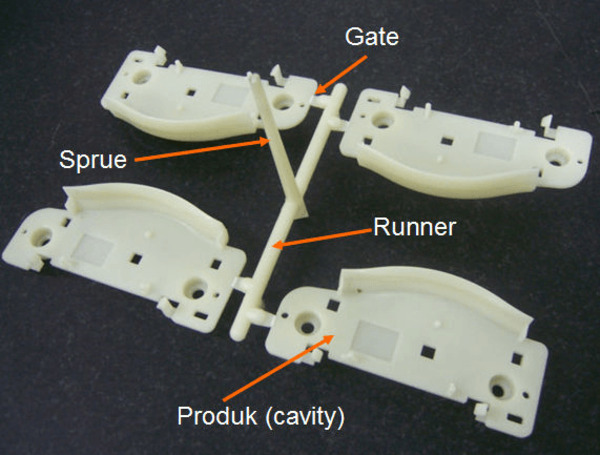

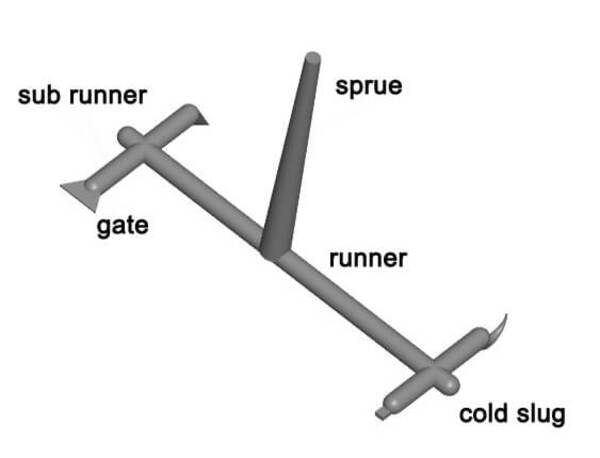

Components of a Cold Runner System

A typical cold runner system consists of the following parts:

Nozzle: Connects the injection molding machine to the mold, guiding molten plastic into the mold.

Main Runner: Located in the center of the mold, connecting the nozzle to the sub-runners.

Sub-Runners: Distribute molten plastic to each mold cavity.

Gate: Connects the sub-runners to the mold cavities, controlling the amount of plastic flowing into the cavities.

Working Principle of Cold Runner Systems

The working process of a cold runner system can be divided into several steps:

Plastic Melting: Plastic pellets are heated and melted in the barrel of the injection molding machine.

Plastic Injection: Molten plastic is injected into the main runner through the nozzle.

Plastic Distribution: Molten plastic is distributed to each mold cavity via the sub-runners.

Plastic Molding: Molten plastic enters the mold cavities through the gates, cooling and solidifying into molded parts.

Ejection: The mold opens, and the cooled molded parts are ejected.

What are the Advantages and Disadvantages of the Cold Runner System?

Cold runner systems are cost-effective and simple to maintain, making them ideal for low to medium production runs. They allow for better material control but can lead to increased waste due to solidified plastic. Key advantages include lower upfront costs and ease of design, while disadvantages involve longer cycle times and potential quality inconsistencies in parts.

Advantages

Low Cost: Cold runner systems2come with lower mold design and manufacturing prices compared to their hot runners counterparts. Because there’s no need for added heating elements or temperature control systems which also makes them an economic choice when budgets are tight or you’re working on things like short runs or price-sensitive projects.

Simple Design: The structure of cold runner systems is relatively simple, making the design and debugging process easier. Mold designers can complete designs faster and reduce debugging time during production.

Wide Application Range: Cold runner molds can be used with many different types of plastic, both thermosetting (which cannot be remelted once they have set) and thermoplastics (which can be heated and reshaped multiple times). Cold runner systems are versatile tooled for making an array of moulded components, especially small- to medium-sized parts

Disadvantages

Material Waste: Solidified plastic is left behind in runners when cold runner injection molding is used for each injection cycle. This means there is material waste – something that has to be dealt with (either processed or recycled) at extra cost before products can be completed.

Lower Production Efficiency: Because cold runners take longer to cool down, they can slow overall cycle times. Compared to hot runner systems, cold runner systems have a disadvantage in production cycles.

Noticeable Gate Marks: The gate marks in cold runner systems are more noticeable, which can impact the appearance quality of the molded parts. For products with high aesthetic requirements, cold runner systems may not be the best choice.

What are the Application Areas of Cold Runner Systems?

Cold runner systems are essential for producing parts in industries such as automotive, consumer products, and packaging. They use a solidified runner that minimizes material waste and is simpler to maintain. Key advantages include lower equipment costs and reduced cycle times for smaller production runs.

Automotive Manufacturing

Cold runner mold systems are commonly utilized in the automotive industry to manufacture items such as headlight houses, dashboards and interior parts. These systems meet the complex structural demands for strength in car components while offering cost-effectiveness.

Electronics and Appliances

In the sector of electronics and appliances, cold runner systems shine in making all sorts of housings and connectors: phone cases, computer housings, plugs.These products require high appearance quality and precision, which cold runner systems can provide.

Medical Devices

Medical devices require high purity and precision in materials. Cold runner systems have advantages in producing items like syringes, infusion sets, and test tubes. They ensure high precision and cleanliness of the products.

Consumer Goods

Cold runner systems are commonly found in the manufacturing of things that consumers buy like toys, utensils and items for the home. A large number of these goods are made – which is where cold runner systems really come into their own. By using them manufacturers can keep production costs down while making lots of items quickly.

How to Design and Optimize the Cold Runner System?

Cold runners are crucial for ensuring uniform temperature distribution and reducing material waste during injection molding. They typically involve a channel through which the molten plastic flows before entering the mold cavities. Key benefits include simplified maintenance, lower initial costs, and the ability to produce a wider range of part sizes and shapes.

Runner Shape and Cross-Section

The performance of a cold runner system is directly affected by the shape and cross-section design of the runners. These can be circular, rectangular or trapezoidal. While circular runners allow for easier flow and better cooling making them desirable they are also harder to make. Rectangular and trapezoidal runners, on the other hand, are easier to manufacture but may offer less efficient flow patterns, sometimes meaning there\’s an increase in resistance.

Circular Runners: These runners are ideal for making high-precision and quality molded parts because they don\’t create much resistance or let heat escape. But they cost a lot to make and are tricky to produce, typically used in high-demand production scenarios.

Rectangular Runners: While easy and inexpensive to produce and manufacture, these runners also lose heat more readily and offer higher flow resistance. They work well for most general molded part production, especially where runner processing precision is not critical.

Trapezoidal Runners: These runners offer a balance between circular and rectangular runners, providing good flow performance and manufacturability, making them a suitable choice for medium-requirement molded part production.

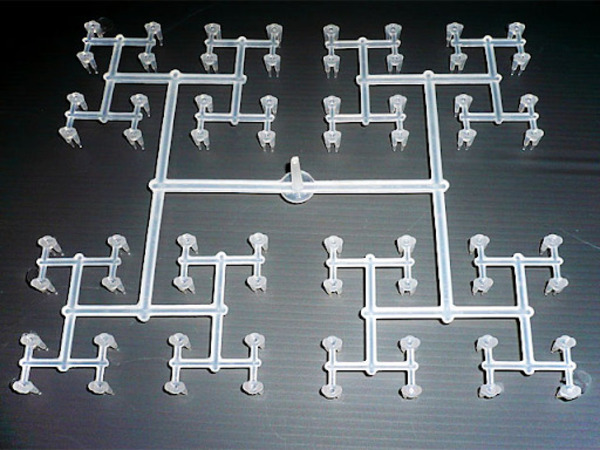

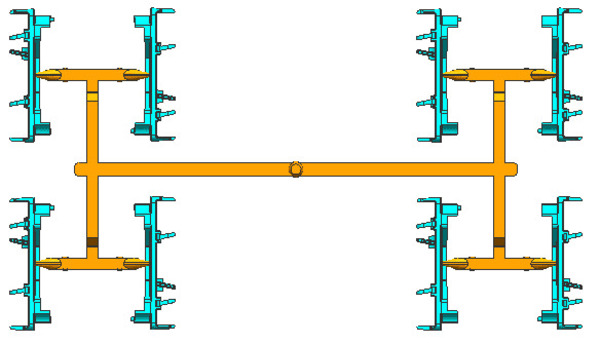

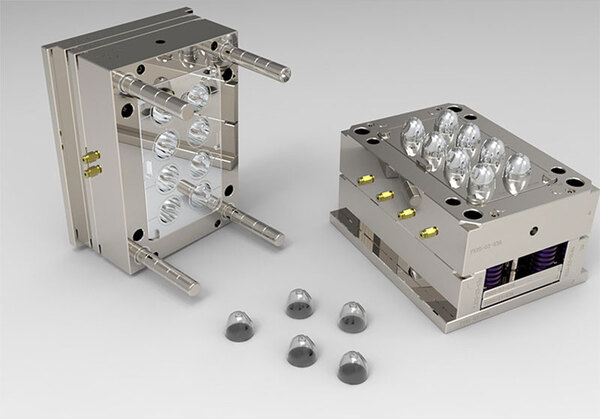

Runner Balance Design

Balanced runner design is crucial for ensuring uniform filling of each mold cavity. Imbalanced runners can cause inconsistent filling times, affecting the quality of the molded parts.

Balanced Runner Layout: By arranging runner lengths and cross-sectional areas reasonably, each mold cavity\’s plastic flow path can be made identical, ensuring uniform filling. This method is suitable for multi-cavity molds3.

Unbalanced Runner Layout: Sometimes, it may not be feasible to have a fully balanced runner system due to how the cavities are positioned and shaped. However, it could be possible to get them at least more nearly balanced by altering their cross-sectional area or shape – or both. To check whether this has worked properly you will need to simulate what happens when the mould fills up (and perhaps also do some experiments).

Gate Type Selection

The choice of gate type directly impacts the molding quality and appearance of the molded parts. Common gate types include pinpoint gates, fan gates, and tunnel gates.

Pinpoint Gate: This type of gate is best suited for small, intricate molded parts. It creates tiny gate marks that hardly show so its appearance is minimally affected; however flow resistance is greater than with other types and there may be occasional clogging.

Fan Gate: This gate type is great for making big, thin-walled parts4. It has a cross-section that widens gradually, so molten plastic flows better and fills the mould more effectively. But because of the way it works, the gate leaves more obvious marks on the surface which may not look so good.

Tunnel Gate: Also referred to as sub-surface gate, finds utility in automated production lines. It has the advantage of automatic gate cutting and high production efficiency but is more complex and costly to design and process.

Cooling System Optimization

Improving production efficiency and quality of parts relies heavily on designing and optimizing the cooling system. By making sure that the cooling system is well-designed you can greatly reduce cooling time5; decrease any shrinking or deformation of parts.

Water Channel Layout: To facilitate efficient heat transfer, it is recommended that cooling water channels be placed in close proximity to runners and cavities. For uniform cooling – and to prevent localized overheating– the layout must also be both regular and rational.

Temperature Control System: Advanced temperature control systems are designed to accurately regulate both the flow and the temperature of cooling water, thereby guaranteeing that cooling always takes place as intended. By making use of intelligent temperature controllers together with sensors it becomes possible not just to monitor mold temperature live but also to promptly make any necessary adjustments to cooling parameters.

Cooling Time Optimization: The cooling time must be optimized depending on both the plastic material’s qualities and the size of a given part. If cooling takes too long, it will lower overall production efficiency. However, if it doesn’t take long enough, there is a chance that deformation could occur—or shrink unevenly. Experiments and simulations are needed in order to decide what would be an optimal amount for cooling time.

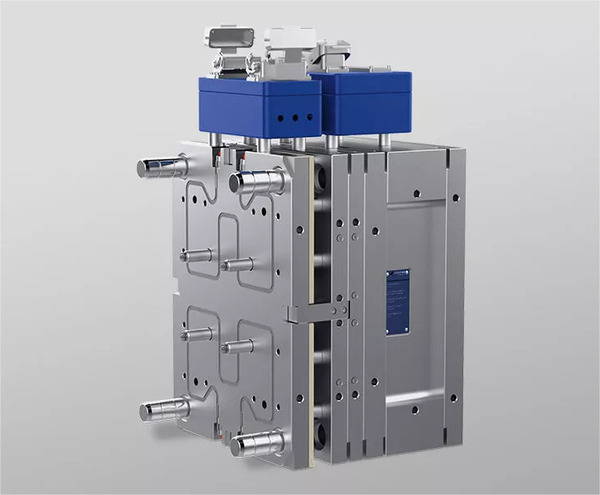

Mold Maintenance and Upkeep

Maintaining and caring for molds is crucial for extending mold life and ensuring production quality. Cold runner system molds can experience wear and aging over long-term use, requiring regular inspection and maintenance.

Cleaning and Lubrication: Basic upkeep includes regular cleaning plus lubrication. Smooth runners and cavities yield better products; achieving this means removing dirt and residual plastic from mold surfaces. Also key: reducing wear by lubricating moving parts.

Inspection and Repair: Wear on mold components, especially runners or cavities, should be assessed often. Catching any damage early is important for keeping production quality high. If necessary, partially replace or refurbish molds.

Storage and Preservation: When storing molds that will not be used for a while, take steps to avoid problems such as rust, moisture or dents. For long-term storage, after cleaning them thoroughly it is wise to apply anti-rust agents before placing the items in dry, well-ventilated areas.

What are the Actual Application Cases of Cold Runner Systems?

Cold runners use a solidified plastic channel to guide material into the mold, leading to reduced complexity and lower costs. They are commonly utilized in packaging, consumer products, and automotive parts. Key benefits include ease of maintenance, lower initial investment, and minimal waste generation.

Automotive Parts Production

Cold runner systems are commonly found in automotive manufacturing, providing parts such as headlight housings, dashboards and interior components. One major car maker has used them to good effect when producing – for example – headlamp housing units. By designing an efficient runners and cooling system it has increased productivity while also improving quality. Hitherto, cycle times for moulding these items fell by one fifth following installation of the new equipment; simultaneously, there was a 15% drop in defects.

Electronic Product Housing Manufacturing

The need for precision and attractive housings is high when it comes to electronics products. This can be seen with smartphones, one company has managed to use design gates alongside cold runners so that they can perform quality injections moulding which produces their cases very accurately. It took a while but after making some changes production speed went up 25% whilst at the same time there were fewer problems with things looking bad – in fact these decreased 30%.

Medical Device Production

Medical equipment needs to be made with high-grade materials that are pure and exact. For example, one firm makes syringes using a cold runner system; by designing molds carefully and fine-tuning cooling systems they can make sure each one is clean as well as accurate. As a result the percentage of usable items rose above 99% while output also went up by 20%.

Consumer Goods Manufacturing

Cold runner systems are commonly found in the manufacturing of everyday consumer items like toys, utensils and household goods. One firm making plastic toys has used them along with fan gates – with impressive results: by balancing runners and improving cooling they cut both waste and production time; now each toy takes 15% less to make while wastage is down by 10%.

What is the Future Development Trend of Cold Runner System?

Cold runner systems facilitate a simpler and cost-effective injection molding process by cooling the plastic before it enters the mold cavity. They are favored for producing smaller parts and achieving faster cycle times. Key advantages include lower tooling costs and reduced material waste, making them ideal for high-volume production runs.

Intelligent and Automated Systems

As Industry 4. 0 progresses, smart technology is being applied to cold runner systems making them more intelligent and automated. With the addition of sensors and control mechanisms, these systems can now be monitored and adjusted in real time – a move which boosts efficiency as well as quality control during production.

Application of New Materials

Using new materials will continue to advance cold runner systems’ development. The arrival of biodegradable and high-performance plastics offers fresh challenges as well as possibilities. Systems must refine designs and processes on an ongoing basis so they can work with characteristics presented by these materials.

Energy Conservation and Environmental Protection

Energy conservation and environmental protection are important future directions for cold runner system development. By optimizing runner and cooling system designs, energy consumption and material waste can be reduced. Using renewable materials and green manufacturing processes will further enhance the environmental performance of cold runner systems.

Precision Manufacturing

Cold runner systems are becoming increasingly important in precision manufacturing6as the demand for accurate and high-quality products rises. By carefully designing these systems and using cutting-edge manufacturing methods, their ability to produce mouldings with precision – as well as consistent products overall.

Conclusion

Cold runner systems are an essential part of injection molding technology. They have advantages such as low cost, simple design, and wide applicability. However, they also have disadvantages such as material waste and lower production efficiency. By optimizing runner design, cooling system design, and mold material selection, the performance of cold runner systems can be improved to meet the needs of various application scenarios. In the future, with the development of intelligent, automated, new material applications, and energy-saving technologies, cold runner systems will face new opportunities and challenges. This article aims to provide readers with comprehensive knowledge of cold runner systems, supporting practical applications and technological innovations.

In the field of injection molding, the continuous optimization and innovation of cold runner systems will drive the development of the manufacturing industry, constantly meeting the growing market demands and technical requirements. We look forward to the widespread application of cold runner systems in various industries, bringing more convenience and benefits to industrial production.

- Learn about WHAT IS A HOT RUNNER : A hot runner system is a molten plastic conveying unit used within an injection mold. ↩

- Learn about Injection Molding Basics: Cold Runner Systems : cold runners are unheated molds and channels used to inject molten plastic into a mold tool cavity. ↩

- Learn about Single Cavity vs Multi Cavity Mold: What are the Differences :In a multi cavity, the mold has more than one cavity, which produces multiple parts simultaneously. ↩

- Learn about How to machining thin-walled parts : Thin-walled parts usually refer to the wall thickness and axial or radial size ratio greater than 1/10 of the parts . ↩

- Learn about The importance of cooling time in injection molding : Cooling time enables molten plastic to solidify, ensuring dimensional stability and directly impacting part quality. ↩

- Learn about What is Precision Manufacturing : Precision manufacturing is creating extremely accurate and complex components from designs. ↩