Brittleness in injection-molded parts can lead to poor performance and failure. Identifying the root causes is essential to improving part durability and production efficiency.

Brittleness in injection molded parts often stems from issues like improper material selection, incorrect processing conditions, or poor mold design. Solutions include adjusting the molding parameters, using impact-resistant materials, and improving cooling rates.

Addressing brittleness requires a thorough examination of material properties and process control. Learn more about how to optimize molding conditions and material choices to enhance part strength and performance.

Improper cooling causes brittleness in injection molded parts.True

Rapid or uneven cooling can cause internal stresses, leading to part brittleness. Proper cooling rates reduce stress and improve part strength.

Using the same material for all injection molded parts eliminates brittleness.False

Different parts require different materials depending on their function. Not all materials are suitable for every application, and incorrect material selection can lead to brittleness.

How Does the Choice of Materials Affect Brittleness in Injection Molded Products?

The material choice in injection molding significantly influences the brittleness of molded products. Selecting the right material is crucial for achieving the desired durability and flexibility.

Materials like ABS, polycarbonate, and nylon provide stronger, more durable molded products. Brittleness is influenced by factors like temperature, material properties, and processing conditions, affecting product performance.

Improper Material Selection

Different types of plastics differ in their mechanical and physical properties. Some materials are prone to brittleness under high stress or low-temperature conditions.

For instance, some of the common The impact strength of polystyrene (PS)1 and Acrylonitrile-Butadiene-Styrene (ABS)2significantly reduce at low temperatures. To inspire this, superior materials with improved toughness and cold resistance for example polypropylene (PP)3 or polyethylene (PE) can be used.

Material Aging

Plastic materials are damaged over time due to factors such as heat, light, and oxygen. As the material ages, the material gradually becomes more brittle, which is due to the presence of chain structures in the material. Adding antioxidants and UV absorbers can enhance the necessary properties of the plastic material and prolong its aging process.

Excessive Use of Recycled Materials

The mechanical strength of recycled materials is usually lower than that of virgin materials. If the proportion of recycled materials is too high, it will cause the product to become brittle more easily.

In addition, recycled materials may have been degraded a little during the reprocessing step. Controlling the proportion of recycled materials and performing necessary quality checks can minimize the brittleness problems caused by the use of recycled materials.

Choosing the right material reduces brittleness in injection molded products.True

Materials with higher toughness, such as ABS or polycarbonate, improve the flexibility and durability of the molded product, reducing brittleness.

All injection molded products are equally brittle regardless of material choice.False

Different materials behave differently under stress. Some, like polycarbonate, are more impact-resistant and less brittle compared to others like polystyrene.

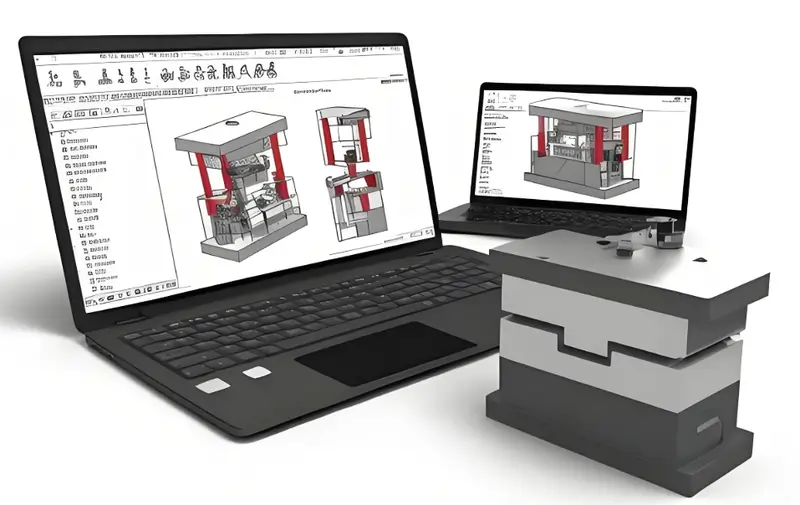

What Effect do Mold Design Factors Have on the Brittleness of Injection Molded Parts?

Mold design factors, such as gate location, cooling rate, and material selection, significantly influence the brittleness of injection-molded parts. Understanding these factors is crucial for producing durable and functional components.

Mold design factors like gate position and cooling time directly affect the crystallization and internal stress in molded parts, influencing their brittleness. Proper design minimizes defects and improves the part’s toughness and longevity.

Runner and Gate Design

Poor design in the runners and gates creates unequal feed of the melt, and resultant stress crack and brittle nature of the cast. Using balanced runner designs and multiple gates can help to increase the melt flow rate and avoid the increased stress concentration.

Mold Temperature Control

Both too low and too high mold temperatures can create issues with the flow of the melt and the rate of cooling. Those, in turn, will lead to material degradation in the case of high mold temperatures, while low temperatures cause issues such as poor melt flow, incomplete filling of the cavity, and internal stress. To address this problem, a temperature controller can be used to effectively control the mold temperature.

Vent Design

Proper vent designing is essential to guarantee that air will be allowed to discharge from the casting freely and formation of zones of weakness in the product that might cause concentration of stress thereby increasing the brittleness of the product. Correct vent and venting slot placement, together with the control of their geometry, allows avoiding a void near the burning-through wall and creating less stress concentrations.

Optimizing mold design reduces brittleness in injection-molded parts.True

Optimized gate placement and controlled cooling reduce internal stress and improve material flow, minimizing brittleness and enhancing part durability.

Using faster cooling rates always reduces brittleness.False

While cooling rate affects brittleness, excessively fast cooling can lead to uneven stress distribution and internal defects, potentially increasing brittleness in some cases.

How Can Processing Parameters be Adjusted to Reduce Brittleness in Injection Molding?

Adjusting processing parameters in injection molding, such as temperature, pressure, and cooling rate, can significantly reduce brittleness in molded parts, improving their durability and performance.

Reducing brittleness in injection molding involves optimizing parameters like injection speed, mold temperature, and cooling time. Lowering the cooling rate and increasing melt temperature can help achieve stronger, less brittle parts.

Injection Speed

Excessive injection speed4that is beyond the required level may result in high shear stress within the mold creating turbulence on the melt breaks molecular chains and thus increases the brittleness of the part.

However, if the injection speed is low or small, it results in non-uniform or in part filled sections and inside voids and injection molding defect in the product. In relation to the above analysis, one of the most important parameters to control in order to reduce the brittleness of the product is the injection speed of the material in question.

Injection Pressure

Injection pressures that are too high add unwanted stresses, break molecular chains, create areas of internal stress concentrations, and decrease the toughness in the process. Low injection pressure has impacts on non-homogeneous product density so it increases brittleness. Thus, controlling the value of injection pressure through experiments can minimize the brittleness of the product.

Melt Temperature

High melt temperature accelerates thermal degradation of materials, destroys molecular chains and causes brittleness. Low melt temperature affects fluidity, leading to uneven filling and quality problems.

The sensitivity of different materials to melt temperature can be solved by optimizing the melt temperature to a certain range to improve product toughness.

Holding Pressure and Cooling Time

Short holding time of the product will lead to uneven internal density and increased brittleness; too long holding time will cause stress in the final product. If the product is demoulded before it is fully solidified, the final product will be deformed and brittle, and too long cooling time will reduce production efficiency. Determining the optimal holding and cooling time through experiments can reduce the brittleness of the product.

Increasing mold temperature reduces brittleness in injection molding.True

Higher mold temperatures allow the material to flow more evenly, reducing internal stresses and preventing brittleness.

Slower cooling rates always reduce brittleness in injection molding.False

While slower cooling rates can reduce brittleness, it may not be optimal for all materials. Each material has its ideal cooling rate to balance strength and efficiency.

How do Environmental Factors Affect the Brittleness of Injection Molded Materials?

Environmental factors, such as temperature, humidity, and exposure to chemicals, significantly influence the brittleness of injection-molded materials, affecting product durability and performance.

Environmental factors can increase or decrease the brittleness of injection-molded materials. High humidity or extreme temperatures may lead to material degradation, while controlled environments can enhance material toughness and longevity.

Humidity

Some plastic materials are highly hygroscopic, and once the plastic absorbs moisture, its mechanical properties will change. For example, polyamide (also known as nylon5) will become brittle and fragile after absorbing moisture. Therefore, the humidity during production and storage should be controlled, or equipment such as dehumidifiers should be used to reduce this problem.

Temperature

Temperature changes in the use environment will affect the brittleness of plastic products. Low temperatures will make the material brittle, and high temperatures will accelerate the aging and degradation of the material. Selecting materials suitable for specific use environments and taking temperature control measures can overcome the effect of temperature changes making the material brittle.

Chemical Environment

Some chemicals can attack the plastic materials thus resulting into a deterioration of the mechanical properties of the material and general brittleness. For example, acidic and alkaline solutions and organic solvents. Understanding the use environment of the product and selecting materials with chemical resistance can effectively reduce brittleness caused by the chemical environment.

Environmental factors can increase brittleness of injection-molded materials.True

Exposure to high humidity, extreme temperatures, and chemicals can weaken the material, making it more prone to cracking or breaking.

Injection-molded materials are unaffected by environmental factors.False

Environmental conditions play a crucial role in material performance, and failure to account for them can lead to product failures in various applications.

How Do Stress Concentration Factors Affect the Brittleness of Injection Molded Products?

Stress concentration factors play a crucial role in the brittleness of injection molded products, influencing their durability and performance under load.

Stress concentration factors in injection molded products can cause localized stress, leading to cracks and brittleness. These factors depend on material properties, design, and molding conditions. Reducing sharp corners and optimizing design can enhance product strength.

Unreasonable Structural Design

Thin walls and sharp corners in product design can easily cause local stress concentration and increase brittleness. Reasonable rounded corner transition or uniform wall thickness should be adopted to avoid stress regional concentration. Finite element analysis and other computer-aided design software tools can be used to evaluate stress and modify product structure during design.

Stress During Assembly and Use

In assembling and during usage external forces can be a source of concentrated stresses which in turn can lead to the creation of brittle materials especially where dynamic loads are being applied because the stress concentration area is likely to develop cracks. So reducing stress concentration and avoiding brittleness; it is necessary to use proper assembly methods as well as proper buffering measures.

Internal Stress

Due to uneven cooling and improper processing parameters during injection molding, internal stress may form within the product. Internal stress can make the product more prone to brittleness under force. Annealing treatment can effectively eliminate internal stress and improve mechanical properties.

Stress concentration factors lead to increased brittleness in injection molded products.True

Localized stress caused by factors such as sharp corners or improper material distribution can lead to cracks and brittleness in molded parts.

Stress concentration factors always cause brittleness in injection molded products.False

Stress concentration factors increase the risk of brittleness but do not always lead to failure, depending on material strength and design optimization.

What Role Does Inspection And Quality Control Play in Preventing Brittleness in Injection Molded Parts?

Inspection and quality control are crucial in detecting and preventing brittleness in injection molded parts, ensuring durability and reliability across various industries.

Effective inspection and quality control processes identify defects like poor material flow, improper cooling, or stress, all of which can lead to brittleness. By implementing thorough checks, manufacturers can reduce the risk of these issues and improve the overall part strength.

Online Detection

During the injection molding production it is possible to apply online detection technologies such as X-ray and ultrasonic testing which enable the real time improvement of product quality and the detection and correction of potential brittleness sources. Thus, utilisation of online detection technologies enhance the product yield and production efficiency of a business.

Material Analysis

In the case of incoming raw material, testing is carried out strictly so that the quality of tensile strength and the impact strength of the material is up to the production standards. Material analysis can determine if there is any possible weakness in the material before it is processed and during production it does not turn brittle.

Product Testing

Test conditions close to actual use can be created, such as aging and cold resistance tests, to detect product brittleness problems early and make corresponding improvements. Product testing is part of quality assurance to ensure that products are used safely and efficiently for their intended use.

Process Validation

Process validation helps to establish that processes before they are produced are as stable and reliable as is required before they are used in production. Process validation, patterns of small-batch trial production, parameter optimization, etc. , and performance testing can play an important role in controlling the brittleness during production.

Inspection and quality control reduce brittleness in injection molded parts.True

Through careful inspection, defects leading to brittleness, such as air pockets or improper curing, can be identified and corrected before parts are used.

Quality control is always sufficient to prevent brittleness in injection molded parts.False

While quality control significantly reduces brittleness, other factors like material choice and mold design also play a key role in preventing part failure.

What are Some Common Solutions to Address Brittleness in Injection-Molded Products?

Brittleness in injection-molded products can be addressed through various techniques like optimizing material selection, adjusting processing conditions, and adding reinforcements to improve durability and toughness.

Common solutions to reduce brittleness include using impact-resistant polymers, modifying mold temperature, adjusting cooling rates, and adding fillers or plasticizers to enhance material flexibility. These methods help improve the product’s resilience and reduce breakage risks.

Optimizing Material Selection

Choose the right plastic type according to the end use and performance requirements. When high toughness is required, you can choose better materials such as polyethylene (PE) and polypropylene (PP). When high temperature resistance or chemical corrosion resistance is required, you can choose polyamide (PA) and polyester (PET) materials.

Improving Mold Design

Design runners and gates to ensure uniform melt flow. Control mold temperature to ensure that the temperature does not reach extreme levels. It is recommended to use multiple gates as a means to reduce stress concentration. Optimize vent design to ensure smooth air discharge and avoid voids and stress concentration.

Adjusting Processing Parameters

Control the injection speed and pressure within a reasonable range to make the melt fill the mold cavity evenly and reduce internal stress. Change the melt temperature according to material properties to prevent material damage. Other process parameters such as holding pressure 6 and cooling time7 should also be set to make the product material density evenly distributed and reduce the impact of residual stress.

Improving Production Environment

Control the humidity and temperature of the production environment, as this will affect the moisture content of the materials. Dehumidification equipment can be used for sensitive items. Take appropriate chemical protection measures to avoid chemical environment from corroding materials.

Reasonable Structural Design

In the design the thin walls and sharp corners should not be provided instead of this gradual transitions and equal thickness of the walls are the best option. The component stress should be equally distributed during assembly and use so that stress concentration is avoided. Make use of the finite element analysis software to determine areas of improvement with regards to the structure of specific products.

Enhancing Detection and Quality Control

Use online detection technology to monitor product quality in real time. Strictly test raw materials to ensure that they meet production requirements. Simulate actual use environment testing to detect brittleness problems as early as possible and make improvements. Conduct extensive process verification of new processes and new materials to determine whether they are stable and reliable.

Using impact-resistant materials reduces brittleness in injection-molded products.True

Materials like PC/ABS blends and polycarbonate offer higher impact resistance, improving the toughness of molded parts.

Slower cooling rates always prevent brittleness in injection-molded parts.False

While slower cooling can reduce internal stresses, overly slow cooling may lead to longer cycle times and potential warping, which does not always prevent brittleness.

Conclusion

The factors that lead to brittleness of the injection molded parts are numerous and they are related to material, mold and process conditions as well as environmental factors. This paper focuses on analyzing these factors and determining corresponding measures of optimisation to decrease brittleness in injection moulded parts and increase quality of products.

As a result, it remains required to focus on details as well as refine and optimize procedures and designs to eliminate the brittleness problems.

Injection molding process is a complex process that requires comprehensive consideration of various factors to produce high-quality products.

By selecting the right material with scientific approach, appropriate design of molds, employ suitable methods of processing and implementing quality control measures, the brittleness-dilemma shall be solved hence enhancing production and customers’ satisfaction. With the development of plastic injection molding technology, more and better plastic products will be supplied to different fields in the future.

-

Learn about Polystyrene : Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. ↩

-

Learn about ABS Injection Molding Processing Guide : ABS plastic is a terpolymer of three monomers, acrylonitrile (A), butadiene (B) and styrene (S). ↩

-

Learn about Polypropylene : Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. ↩

-

Learn about Injection Speed : The injection speed essentially determines the degree of molecular orientation and, thus, affects the adhesion, orientation, and shrinkage . ↩

-

Learn about PA6, PA66, PA12, and PA1010 are four kinds of nylon injection molding process introduction : NylonPolyamide (PA for short) is a plastic composed of polyamide resins. ↩

-

Learn about Holding Pressure in Injection Moulding: What is it and How to Set it? The setting of hold pressure is aimed to prevent resin backflow . ↩

-

Learn about How to Determine Injection Molding Cooling Time : 80%. That is how much of the molding cycle is spent cooling the plastic part. ↩