Precision, quality, and efficiency are of utmost importance in the realm of medical device and manufacturing processes. The ability to produce reliable and precise medical devices is crucial for the well-being of patients and the advancement of healthcare. In recent years, injection molding has emerged as a game-changer in this field, revolutionizing the production process for medical devices. This article aims to explore the benefits of injection molding and shed light on its significant contributions to the healthcare industry.

Medical device manufacturing requires a meticulous approach, as even the slightest deviation in design or production can have serious implications for patient safety. Injection molding, with its precision and versatility, has become a preferred method for creating various components and devices used in the medical field. By injecting molten material into specialized molds, this technique allows for the production of intricate and complex parts with consistent quality and performance.

The benefits of injection molded devices are manifold. Not only does it offer cost-effective solutions for manufacturers, but it also enables design flexibility, enhanced product quality, faster production cycles, and scalability. These advantages play a pivotal role in meeting the increasing demand for innovative injection molded medical devices while ensuring their safety and effectiveness.

In the following sections, we will delve into the specific benefits and advantages that injection molding brings to the table not all medical devices have. From cost savings to design flexibility and improved product quality, injection molding has proven its worth in the medical device manufacturing industry. By understanding these benefits, we can appreciate the vital role that injection molding plays in creating life-changing medical devices.

II. Cost-effectiveness of Injection Molding process

Injection molding offers significant cost advantages, making it an attractive choice for medical device manufacturers. Let’s explore the key factors that contribute to the cost-effectiveness of injection molding:

High-volume production and reduced per-unit costs:

Injection molding enables high-volume production of medical devices. The process allows for the creation of multiple parts simultaneously, resulting in economies of scale. By producing a large number of devices in a single production run, manufacturers can significantly reduce per-unit costs. This is particularly beneficial for medical devices that are in high demand, such as syringes or catheters.

Automation and repeatability for enhanced cost-effectiveness:

Injection molding is an automated manufacturing process that utilizes advanced machinery and technology. Once the initial setup is completed, the process can be replicated consistently with minimal human intervention. The automation and repeatability inherent in injection molding lead to reduced labor costs, as fewer workers are required for operation and monitoring. This not only enhances cost-effectiveness but also ensures consistent quality and reduces the risk of human error.

Attractiveness for medical device manufacturers:

The cost-effectiveness of injection molding makes it an attractive option for medical device manufacturers, particularly those aiming for high-volume production. The ability to produce large quantities of medical devices at a lower cost per unit provides a competitive edge in the market. It allows manufacturers to meet demand efficiently, keep prices competitive, and improve overall profitability. Moreover, cost savings achieved through injection molding can be reinvested in research and development efforts to drive innovation in the medical device industry.

By capitalizing on high-volume production capabilities, leveraging automation, and achieving cost savings, injection molding offers a compelling cost-effective solution for manufacturing medical devices. Its ability to streamline production processes and reduce per-unit costs contributes to the affordability and accessibility of medical devices, ultimately benefiting healthcare providers and patients alike.

III. Design Flexibility in Injection Molding process

Injection molding offers remarkable design flexibility, allowing for the creation of intricate and complex designs that meet the specific requirements of medical devices. Let’s explore the key aspects of design flexibility in injection molding:

Ability to create intricate and complex designs:

Injection molding excels in producing intricate and highly detailed designs for medical devices. The process involves injecting molten material into specialized molds with precision and accuracy. This enables the creation of complex geometries, intricate features, and fine details that may be challenging to achieve with other manufacturing methods. Injection molding unlocks the potential for innovative designs that cater to the diverse needs of the medical industry.

Thin walls, textures, and dimensional accuracy:

Injection molding enables the production of medical devices with thin walls while maintaining structural integrity. Thin-walled parts are particularly desirable for devices such as catheters or surgical instruments, where flexibility and maneuverability are crucial. Furthermore, plastic injection molding allows for the incorporation of various textures, which can improve grip or facilitate ease of use for medical professionals.

Dimensional accuracy is paramount in the medical field, where precise fit and compatibility are critical. Injection molding ensures high dimensional accuracy, producing parts that consistently meet tight tolerances. This level of precision enables proper assembly, seamless integration with other components, and optimal functionality of plastic medical devices.

Importance of design flexibility for medical devices:

Design flexibility is of utmost importance in medical device manufacturing. Each device serves a unique purpose and requires specific design considerations to meet its intended function. Injection molding provides the versatility and adaptability needed to accommodate the diverse range of medical devices, including joint replacements, surgical instruments, or housing for medical equipment.

Design flexibility also enables the integration of additional features or components into a single injection-molded part, reducing the need for multi-step assembly processes. This streamlines production improves efficiency, and enhances the overall performance and reliability of medical devices.

By leveraging the design flexibility of plastic injection molding, manufacturers can create highly customized and tailored medical devices that meet the specific needs of healthcare professionals and patients. The ability of injection molded parts to achieve intricate designs, thin walls, textures, and dimensional accuracy empowers innovation in the medical industry, facilitating advancements in healthcare and improving patient outcomes.

IV. Enhanced Product Quality through Injection Molding for medical injection molding

Injection molding molten plastic ensures a high level of product quality, making it a preferred choice for manufacturing medical devices. Let’s explore the key factors that contribute to enhanced product quality in plastic injection molding:

Precise control over temperature, pressure, and material distribution:

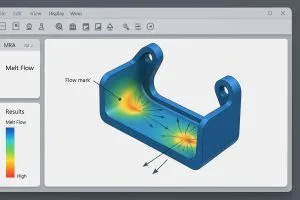

Injection molding provides precise control over various process parameters, including temperature, pressure, and material distribution. The ability to accurately regulate these factors ensures consistent and reliable results. By maintaining optimal conditions throughout the molding process, manufacturers can achieve excellent part quality and minimize variations between individual parts.

Consistent parts with minimal defects:

Injection molding produces consistent parts with minimal defects. The automated nature of the process ensures that each part is identical to the others, meeting stringent quality standards. The use of advanced machinery and technology, coupled with precise control over process parameters, minimizes the risk of defects such as warping, sink marks, or air voids. This level of consistency and minimal defect rate is crucial for medical devices that require a precise fit, performance, and compatibility with other components.

Use of specialized materials for safety and reliability:

Injection molding allows for the use of specialized materials specifically designed for medical applications. Medical-grade polymers, known as medical-grade plastics, offer exceptional chemical properties, biocompatibility, and durability. These materials meet strict regulatory requirements and ensure the safety and reliability of medical devices. The use of medical-grade polymers in injection molding guarantees that the resulting parts are suitable for use in the medical field.

Moreover, the ability to utilize a wide range of materials, including specialized plastics and other compounds, enables manufacturers to select the most appropriate material for each specific medical device. This versatility allows for customization based on the unique mechanical properties and requirements of the device, ensuring optimal performance and patient safety.

By providing precise control over process parameters, minimizing defects, and utilizing specialized materials, injection molding ensures enhanced product quality in the production of medical devices. The stringent quality control measures in place throughout the injection molding process contribute to the reliability, functionality, and safety of medical devices used in various healthcare applications.

Conclusion

Injection molding has revolutionized the production of medical devices, offering numerous benefits that contribute to the advancement of healthcare. Throughout this article, we have explored the various advantages of using injection molding for medical devices. Let’s recap these benefits and highlight the significant role injection molding plays in the healthcare industry.

In conclusion, injection molding has revolutionized the manufacturing of medical devices, offering numerous benefits in terms of cost-effectiveness, design flexibility, enhanced product quality, faster production cycles, scalability, consistency, and sustainability. Its significant role in the healthcare industry ensures the development and production of reliable and innovative medical devices. As medical technology continues to evolve, injection molding will continue to shape the future of healthcare applications, driving advancements that enhance patient care and improve overall well-being.