Introduction:

Injection molding is a highly efficient manufacturing process used for mass production of high-quality plastic parts in large volumes. Thanks to advances in technology, injection molding automation has become more common across various industries – and injection molding is no exception. Here we explore its many advantages as a revolutionizer of this industry.

Automation has made significant strides toward increasing production capabilities and overall efficiency over the years, and injection molding processes which previously relied heavily on manual labor is being transformed by automated systems and advanced technologies.

In this article, the purpose is to explore the advantages of automating the injection molding process. We will focus on how automation increases efficiency, ensures consistent quality, reduces costs and provides cost savings opportunities while simultaneously increasing flexibility and workplace safety in injection molding sector.

II. What is Automation in Injection Moulding?

Automation plays a pivotal role in revolutionizing the injection molding process by leveraging the integration of robotic systems and advanced technologies. In this section, we will define automation in the context of injection molding, explain how robotic centralized control system and advanced technologies are incorporated, and highlight the specific tasks that can be automated.

Automated injection molding refers to the utilization of robotics, computer controls, and other advanced technologies to streamline and optimize the manufacturing process. It involves the implementation of robotic systems that perform various tasks, replacing or assisting human operators.

Robotic systems are equipped with sophisticated sensors, actuators, and programming capabilities that enable precise and efficient execution of tasks. They can be seamlessly integrated into the injection molding workflow to handle a range of responsibilities, from material handling and mold setup to part ejection and quality control.

Tasks that can be automated in the injection molding process include:

1.Material Handling:Automated processes can efficiently handle raw materials, such as plastic pellets, by automatically loading them into the injection molding machine. This eliminates the need for manual feeding and ensures consistent material supply.

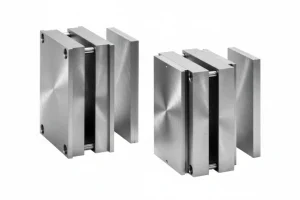

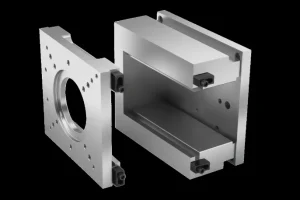

2.Mold Setup:Robotic systems can facilitate the setup of molds by precisely positioning and aligning them within the injection molding machine. They can handle heavy molds and ensure accurate placement, reducing setup time and enhancing efficiency.

3.Part Ejection:Automated systems can swiftly remove finished parts from the mold and transfer them to subsequent stages of the production line. This eliminates the need for manual intervention and reduces the risk of damage to the parts.

4.Quality Control:Robotic inspection systems can be integrated to inspect and ensure the quality of produced parts. These systems use cameras, sensors, and machine learning algorithms to identify defects, measure dimensions, and verify adherence to specifications.

5.Packaging:

Automated packaging systems can efficiently package the finished parts, ensuring proper labeling, sorting, and stacking. This improves productivity and consistency in the packaging process.

By automating these tasks, manufacturers can achieve higher levels of precision, consistency, and speed in the injection molding process. Automation technology eliminates the limitations associated with human intervention, such as human error, fatigue, and variability, resulting in enhanced overall efficiency and productivity.

III. Advantages of Automation in Plastic Injection Molding

Automation in plastic injection molding brings forth numerous advantages, ranging from enhanced efficiency and consistent quality to cost savings and increased flexibility. Let’s delve into each of these advantages in detail:

A. Enhanced Efficiency:

Automation tools eliminate the need for manual labor and significantly reduce human errors, leading to enhanced efficiency in injection molding projects. Some key benefits include:

- Elimination of manual handling and repetitive tasks, allowing operators to focus on higher-value activities.

- Streamlined processes from material handling to packaging, resulting in faster production cycles and reduced downtime.

- Increased output and improved overall productivity, enabling manufacturers to meet customer demands more efficiently.

B. Consistent Quality:

Automation plays a vital role in ensuring consistent quality throughout the injection molding process. The advantages include:

- Precision and accuracy achieved through automated injection molding equipment systems, which follow programmed instructions precisely.

- Parts consistently meet required specifications, reducing variations and defects.

- Improved customer satisfaction due to the production of high-quality parts.

- Reduced waste and rejections, leading to cost savings.

C. Cost Savings: Implementing automation in plastic injection molding brings several cost-saving opportunities:

- Reduction in labor costs by minimizing the reliance on manual labor.

- Continuous operation maximizes production uptime, leading to higher throughput and increased revenue.

- Optimal material usage and minimized errors contribute to reduced material waste and cost savings.

- Efficient production of smaller batches or customized plastic products, reducing the need for dedicated production runs.

D. Increased Flexibility:

Automation enhances the flexibility of the injection molding process, allowing manufacturers to adapt to changing requirements. The benefits include:

- Quick switchovers between molds and part designs, enabling efficient production of different products.

- Shorter setup times, facilitating the production of smaller batches or customized products.

- Real-time monitoring and adjustments ensure optimal performance and minimize deviations.

By embracing automation in plastic injection molding, manufacturers can optimize their operations, achieve higher efficiency, improve product quality, reduce costs, and enhance their competitive edge in the market.

In conclusion, automation brings a multitude of advantages to the injection molding process, revolutionizing production capabilities, and improving overall performance. The integration of advanced technologies and robotic systems allows for enhanced efficiency, consistent quality, cost savings, and increased flexibility. Embracing automation is a strategic step for manufacturers seeking to thrive in the evolving landscape of plastic injection molding.

IV. Can Injection Molding be Automated?

Automation has significantly transformed the injection molding secondary processes, leveraging advancements in robotics, machine learning, and artificial intelligence. In this section, we will address the question of whether injection molding can be automated machines, explore the technological advancements driving automation, and highlight the possibilities of automation in various aspects of the injection molding process.

Injection molding can indeed be automated, and automation brings numerous benefits to the process. Technological advancements have paved the way for automation in the following ways:

- Robotics: Robotic systems have evolved to become highly capable in the injection molding industry. These robots are equipped with precise control systems, sophisticated sensors, and intuitive programming interfaces. They can perform a wide range of tasks, such as material handling, mold setup, part ejection, and packaging.

- Machine Learning and Artificial Intelligence: Automation in injection molding is further enhanced by the integration of machine learning and artificial intelligence (AI). These technologies enable robots to learn and adapt to changing conditions, optimize process parameters, and make real-time adjustments. Machine learning algorithms can analyze vast amounts of data to detect patterns and identify potential issues, leading to improved process control and quality assurance.

Automation possibilities in various aspects of injection molding include:

- Material Handling: Robots can handle and load raw materials into the injection molding machine, ensuring consistent material supply and reducing manual intervention.

- Mold Setup: Robotic systems can accurately position and align molds within the injection molding machine, reducing setup time and enhancing efficiency.

- Part Ejection: Robots can swiftly and precisely remove finished parts from the mold, reducing the risk of damage and improving overall productivity.

- Quality Control: Automation allows for the integration of robotic inspection systems that use cameras, sensors, and AI algorithms to inspect and ensure the quality of produced parts. These systems can identify defects, measure dimensions, and verify adherence to specifications.

- Packaging: Automated packaging systems can efficiently package the finished parts, ensuring proper labeling, sorting, and stacking.

These advancements in automated injection molding technology have transformed injection molding into a highly efficient and precise process, enabling manufacturers to achieve higher levels of productivity, quality, and cost-effectiveness.

In conclusion, injection molding can be successfully automated by leveraging advancements in robotics, machine learning, and artificial intelligence. The integration of automated systems and technologies allows for enhanced control, efficiency, and quality throughout the injection molding process. Manufacturers can benefit from increased productivity, improved product consistency, reduced labor costs, and optimized resource utilization by embracing automation in their injection molding operations.

Conclusion:

Automation in injection molding also offers increased flexibility. Quick switchovers between molds and part designs enable efficient production of different products. Shorter setup times allow for the production of smaller batches or customized products, catering to specific market demands. Real-time monitoring and adjustments ensure optimal performance and minimize process deviations.

Embracing automation in the injection molding industry is of significant importance. It allows manufacturers to optimize their production capabilities, meet customer demands more effectively, and stay competitive in the market. Automation provides a competitive edge by improving efficiency, ensuring consistent quality, and reducing costs. It also enables manufacturers to adapt to changing market needs and produce a wide range of products efficiently.

In conclusion, the impact of automation on the injection molding process cannot be overstated. The benefits of enhanced efficiency, consistent quality, cost savings, and increased flexibility make automation a vital component in staying competitive and thriving in the industry. By embracing automation, experienced professional plastic molder can unlock their full production potential, satisfy customer requirements, and position themselves as industry leaders in the dynamic market landscape.