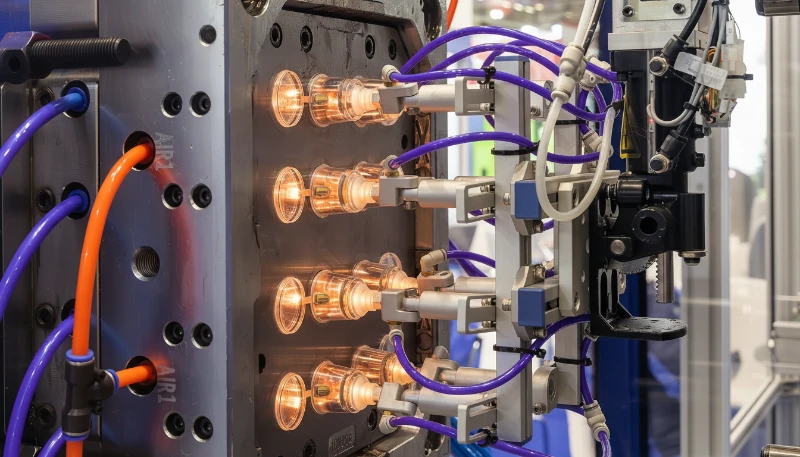

– Automated injection molding enables 24/7 production with consistent cycle times, eliminating human variability and dramatically increasing throughput

– Robotic part removal and in-line inspection systems reduce labor costs while simultaneously improving quality by catching defects before they accumulate

– Automation enables “lights-out” manufacturing—unattended overnight and weekend production that maximizes machine utilization without proportional labor increases

– Data-driven process monitoring in automated cells provides real-time quality data that supports continuous improvement and regulatory documentation requirements

What Does Automated Injection Molding Actually Mean in Practice?

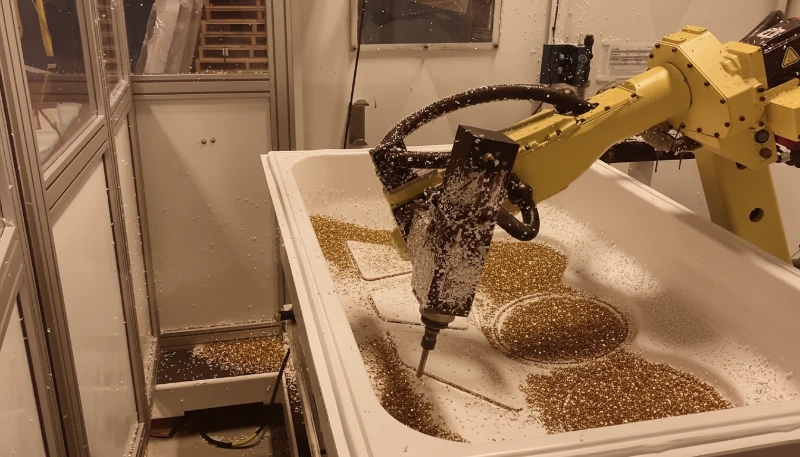

Automated injection molding integrates the core injection process with robotic systems, conveyors, vision systems, and data acquisition tools to minimize human intervention in the production cycle. In our factory, “automated” doesn’t mean a single robot—it means a coordinated cell where the injection machine, a six-axis or Cartesian robot for part removal, a conveyor, an inline vision inspection system, and a packaging station all communicate and operate as a unified system. The injection machine triggers the robot on ejection, the robot places parts on the inspection conveyor, the vision system makes accept/reject decisions, and conforming parts flow directly into packaging—all without a human touching a part between molding and boxing.

The level of automation can be scaled to match production requirements. Entry-level automation might be a simple Cartesian pick-and-place robot that removes parts from the mold and drops them onto a conveyor. More sophisticated cells incorporate vision guidance for part orientation, servo-driven end-of-arm tooling that handles complex part geometries, and MES (manufacturing execution system)1 connectivity that logs every cycle’s process parameters for traceability. We’ve implemented both ends of this spectrum for customers across medical devices, consumer electronics, and automotive.

How Does Automation Improve Production Output and Machine Utilization?

The most immediate benefit of automation is consistent, uninterrupted production. Human operators fatigue, take breaks, and vary their actions from cycle to cycle. Robots don’t. In our automated cells, we’ve measured cycle-to-cycle consistency improvements of 15–25% versus manually-tended machines, because robotic part removal occurs at exactly the same point in the ejection phase every cycle—no hesitation, no variation, no dropped parts. This consistency directly translates to better part quality: cooling is predictable, warpage is minimized, and dimensional variation between parts narrows.

Machine utilization—the percentage of time a machine is actively cycling versus idle—jumps dramatically with automation. A manually-tended machine running a 30-second cycle might achieve 70–75% utilization when accounting for operator breaks, shift changes, and manual part handling time. An automated cell running the same cycle routinely achieves 90–95% utilization. Over a year of production, this difference compounds to millions of additional parts from the same capital asset. The table below shows the impact of automation on key production metrics:

| Metric | Manual Operation | Automated Cell | Improvement |

|---|---|---|---|

| Machine Utilization | 70–75% | 90–95% | +20–25% |

| Cycle-to-Cycle Consistency | ±5–10% | ±1–2% | 5× improvement |

| Defect Rate | 0.5–2.0% | 0.05–0.2% | 10× improvement |

| Labor per 1,000 Parts | 2–4 hours | 0.2–0.5 hours | 8–10× reduction |

| Shift Coverage | 8–16 hours/day | 24 hours/day | +50–200% |

What Are the Quality Benefits of Automated Inspection in Injection Molding?

Inline automated inspection is where automation delivers its most dramatic quality improvements. A human operator inspecting parts at the end of a production line is limited by fatigue, attention span, and the physical rate at which they can examine parts—typically 100–200 parts per hour for a detailed visual inspection. A machine vision system operating inline can inspect every part at the machine’s cycle rate—potentially 2,000+ parts per hour—checking dozens of dimensions and cosmetic criteria simultaneously. We’ve deployed vision systems that measure critical dimensions to ±0.02 mm accuracy and detect surface defects as small as 0.1 mm across 100% of production output.

Beyond catching defects, automated inspection generates process data. Every part’s measurements feed into SPC (statistical process control)2 charts that trend over time, alerting process engineers before dimensions drift out of specification rather than after a batch of non-conforming parts is produced. This predictive quality capability is impossible to replicate with manual inspection.

“Automated injection molding cells require constant human supervision to function correctly.”False

Modern automated injection molding cells are designed for unattended “lights-out” operation. Integrated fault detection, automatic purge sequences, alarm systems, and remote monitoring via OPC-UA or MQTT connectivity allow cells to run unattended through nights and weekends. Human intervention is required for material changes, tooling maintenance, and exception handling—not for continuous production monitoring.

“Automation ROI in injection molding typically pays back within 12–24 months for high-volume production.”True

Automation investments in injection molding typically recover their cost within 1–2 years through reduced labor costs, higher machine utilization, lower defect rates, and reduced scrap. For operations running three shifts on high-volume consumer products, we’ve seen ROI periods as short as 8–10 months when the full cost of manual labor—including overtime, benefits, and quality costs—is included.

How Does Lights-Out Manufacturing Work in Automated Injection Molding?

Lights-out manufacturing—production that runs fully unattended through nights, weekends, and holidays—is achievable in injection molding when automation is properly implemented. The prerequisites are: reliable tooling (well-maintained, with sufficient cycle life remaining), automatic part removal so parts don’t accumulate in the mold, automatic reject sorting so defective parts don’t contaminate good output, hopper loaders with sufficient resin capacity to run through the unattended period, and alarm systems that halt production and notify on-call staff when out-of-tolerance conditions are detected. In our facility, we regularly run lights-out from 10 PM to 6 AM on our highest-volume consumer goods tools, adding 8 hours of production per night with effectively zero incremental labor cost.

The economic impact of lights-out capability compounds quickly. A machine running 16 hours per day with manual operation (two staffed shifts) versus 23 hours per day with lights-out automation represents a 44% increase in effective production capacity from the same capital investment. Over a year, this difference is the equivalent of adding a new machine without the capital cost—or fulfilling a customer order months earlier than would otherwise be possible.

What Industries Benefit Most from Automated Injection Molding?

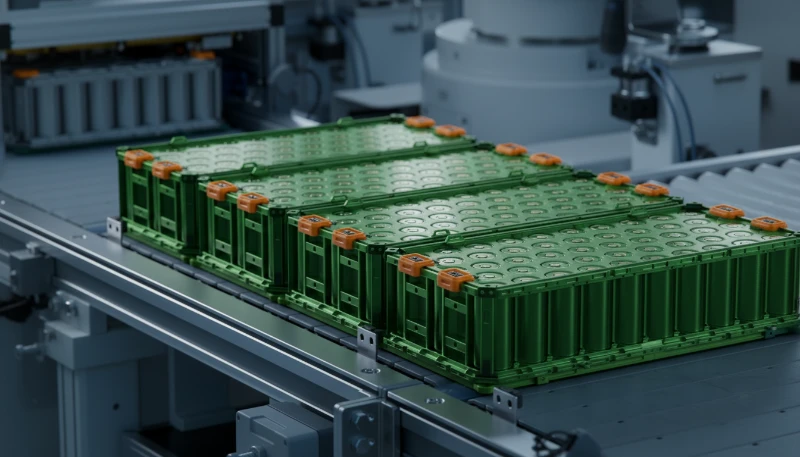

Every high-volume injection molding application benefits from automation, but three industries have driven the most aggressive automation adoption: medical devices, consumer electronics, and automotive. Medical device manufacturing has strict GMP3 requirements that mandate documented traceability and controlled manufacturing conditions. Automated cells with data logging satisfy these requirements far more efficiently than manual production: every part produced is linked to its specific machine, tool, material lot, and process parameters. Consumer electronics manufacturers face the dual pressure of extremely high volumes and cosmetically exacting standards—automation delivers both the throughput and the 100% inspection these applications require. Automotive parts demand zero-defect quality on safety-critical components, and automated vision inspection provides the statistical confidence that manual sampling cannot.

| Industry | Primary Automation Driver | Key Automation Features | Typical ROI Period |

|---|---|---|---|

| Medical Devices | Regulatory traceability, cleanroom requirements | Data logging, cleanroom robots, vision inspection | 18–24 months |

| Consumer Electronics | Volume, cosmetic quality | 100% vision inspection, multi-cavity part handling | 12–18 months |

| Automotive | Zero-defect, PPAP documentation | SPC integration, in-mold labeling, dimensional gauging | 12–24 months |

| Consumer Goods/Packaging | Cost per part, throughput | Lights-out operation, multi-cavity handling | 8–14 months |

“Automation in injection molding only benefits very large operations; small shops cannot justify it.”False

Entry-level automation—a Cartesian robot with basic part removal capability—can be added to a single injection machine for $15,000–$40,000. For a shop running a high-volume consumer product on one machine, this investment often pays back in under a year through reduced operator time and improved machine utilization. Scalable automation is accessible even to small injection molding operations.

“Inline vision inspection systems can inspect 100% of production output at machine cycle rates.”True

Modern machine vision systems with industrial cameras and AI-assisted defect detection can inspect parts in real-time as they exit the mold—at the machine’s full cycle rate. This is fundamentally different from sampling-based manual inspection, which statistically misses a proportion of defects. 100% inspection with automated vision provides a quality assurance capability that manual methods physically cannot replicate.

Frequently Asked Questions About Automated Injection Molding

- Q: What is the typical investment required to automate a single injection molding machine?

- Entry-level Cartesian robot cells for simple part removal start at $15,000–$40,000 including integration. Full automation cells with six-axis robots, vision inspection, conveyors, and MES connectivity typically run $80,000–$250,000 depending on complexity. The appropriate investment level depends on production volume, part value, and quality requirements—we help customers model ROI to size the automation correctly.

- Q: Can automated cells handle complex multi-component assemblies?

- Yes. Automated cells can incorporate insert loading (feeding metal inserts into the mold before injection), in-mold labeling (placing labels or films in the mold), and post-mold assembly (pressing in bearings, applying adhesives, assembling multi-part units). These cells are more complex to engineer but can eliminate entire secondary assembly departments for the right applications.

- Q: How does automation affect tooling and maintenance requirements?

- Automated production places higher demands on tooling reliability because unplanned downtime in a lights-out cell may go undetected longer than in manually-tended production. We design automated-cell tooling with more conservative ejection systems, hardened wear surfaces, and more frequent scheduled maintenance intervals. The additional tooling investment is more than offset by the productivity gains of continuous unattended production.

- Q: Is automation compatible with quick-change tooling for short runs?

- Yes, and this combination is increasingly common. Quick-change mold systems with standardized clamping and connection points allow tool changes in 5–15 minutes rather than 1–2 hours. Combined with automated part handling, this enables flexible production cells that can switch between multiple product SKUs efficiently while maintaining automation benefits across all runs.

- Q: How does automated injection molding support regulatory compliance for medical devices?

- Automated cells with data logging capture every process parameter for every cycle—melt temperature, injection pressure, cavity pressure, cycle time, and machine ID—creating an electronic batch record that satisfies FDA 21 CFR Part 11 and ISO 13485 requirements. Manual production can generate this documentation, but it requires significant additional record-keeping effort. Automation makes compliance documentation an automatic byproduct of production.

Summary

Automated injection molding transforms the process from a labor-intensive, variable production method into a consistent, data-driven, high-efficiency manufacturing system. The benefits span throughput—20–25% higher machine utilization, 24/7 lights-out capability—quality—10× defect rate reduction through inline vision inspection—and economics—8–10× reduction in labor per part. For industries where documentation, traceability, and zero-defect quality are non-negotiable—medical devices, automotive, consumer electronics—automation isn’t optional; it’s a competitive requirement. In our factory, we’ve seen automation investments pay back in 8–24 months depending on volume and complexity, and the ongoing operational benefits continue to compound for the lifetime of the production program. If your injection molding operation is running high volumes on consistent products, automation is almost certainly the highest-ROI capital investment available to you.

-

Manufacturing Execution System (MES): A software platform that tracks and controls manufacturing processes on the factory floor in real time, collecting data from machines and operators to provide traceability, scheduling, and quality management functions. ↩

-

Statistical Process Control (SPC): A quality control methodology that uses statistical methods to monitor and control a manufacturing process, detecting trends and variations before they result in defective output through control charts and process capability indices. ↩

-

Good Manufacturing Practice (GMP): A set of regulations and guidelines issued by regulatory authorities (FDA, EU) ensuring that products are consistently produced and controlled according to quality standards appropriate to their intended use, particularly critical in medical device and pharmaceutical manufacturing. ↩