Introduction

Injection molding and 3D printing are two manufacturing techniques that have revolutionized the industry in recent years. Both methods have their own advantages and drawbacks, yet both are widely used for producing plastic parts and components. Injection molding has been around for decades now and remains widely employed today, while 3D printing (also referred to as additive manufacturing) is a relatively new technology which has gained popularity due to its capacity for quickly creating complex geometries and producing prototypes themselves.

Two manufacturing methods are vitally important in their capacity for producing parts and components with high accuracy and repeatability. Plastic injection molding, for instance, has the advantage of mass production due to its capacity for quickly producing identical components at low costs – making it ideal for mass production. On the other hand, 3D printing excels at small batch runs, rapid prototyping, as well as parts with intricate shapes and designs.

In this article, we’ll examine the advantages of 3D printing vs. for plastic injection molding and compare their pros and cons. By the end, you’ll have a better grasp on how these two technologies can be combined to produce high-quality plastic parts and components for various applications.

II. Benefits of 3D Printing for Injection Molding

The advantages of 3D printing over injection molding

3D printing offers several advantages over traditional plastic injection molding, such as the speedy production of prototypes and molds without need for costly tooling or machining. Plus, designs can be modified and refined easily with 3D printing – leading to a quicker development cycle overall.

Another advantage of 3D printing is its capacity for producing complex geometries and designs which would otherwise be impossible with plastic or injection molding machines. Furthermore, 3D printing enables parts with intricate internal features or thin walls which would be impossible with traditional injection molding techniques.

Furthermore, 3D printing provides greater design freedom as it does not require the use of a fixed, injection molding machine like injection molding does. This enables the production of customized or personalized parts and components with ease.

Finally, 3D printing is an economical solution for low-volume production runs. Injection molding requires costly tooling and molds that may not be feasible in smaller batches, making 3d printed mold this method ideal.

Overall, 3D printing offers several advantages over injection molding, such as faster prototyping and development, greater design freedom, and the capacity for complex geometries and designs. These advantages make 3D printing an invaluable resource for those seeking high-quality plastic parts with greater efficiency and cost effectiveness.

Explain how 3D printing can improve the injection molding process

3D printing can greatly enhance the injection molding process in several ways. One major benefit is its speedy production of molds and prototypes, enabling designers to iterate more rapidly on designs before investing in costly injection molds. Furthermore, 3D printers enable manufacturers to easily create molds of various shapes and sizes so they can test out a design prior to investing in more costly tools.

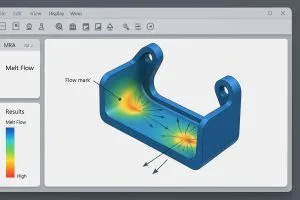

Another advantage of 3D printing for injection molding is its precision and accuracy in producing complex parts. 3D printing makes it possible to produce parts with uniform wall thickness, which ensures consistent quality across injection molded products. Furthermore, 3D printing can be utilized to produce runner systems and other essential components needed in the injection molding process – eliminating additional machining or tooling requirements.

3D printing can also be employed to manufacture aluminum molds, with lower thermal conductivity, leading to faster cooling times during injection molding. This helps reduce cycle times and enhance manufacturing efficiency.

Furthermore, 3D printing can be employed to produce 3D printed injection molds at an economical cost that are ideal for small batch production or prototyping. While they may not be as durable as metal molds, 3D printed injection molds provide manufacturers with a quick way to create functional parts with tight tolerances and precise dimensions.

Overall, 3D printing can enhance the injection molding process by providing faster and more efficient injection mold part production, higher precision in part production, as well as making molds with lower thermal conductivity for faster cooling times. These advantages make 3D printing an invaluable addition to the injection molding process and a key tool for manufacturers looking to produce high-quality plastic parts and components.

III. Benefits of 3D Printing

3D printing offers several advantages that can be utilized in injection molding. Here are five of them:

Design Flexibility – 3D printing offers greater design freedom because it does not require the use of a fixed mold, enabling customization or personalized parts and components with ease. This benefit can even be extended into injection molding by using 3D printing to quickly produce prototypes and molds that can be modified and refined before investing in costly, injection mold and molds.

Faster Prototyping – 3D printing allows for the rapid production of prototypes, which can be used to assess a design’s functionality and feasibility before investing in costly injection molds. This helps reduce development time and costs, improving the efficiency of the additive manufacturing process overall.

Reduced Costs – 3D printing can be a cost-effective solution for low volume production runs, as tooling require machining, and molds required for injection molding may not be affordable in smaller batches. Furthermore, 3D printing eliminates the need for additional machining or tooling, further cutting costs.

Production of Complex Geometries – 3D printing allows the production of parts with intricate shapes and designs that would be impossible or impracticable with plastic injection molding. This advantage can be applied to plastic injection molding by using 3D printing to create molds mold parts and prototypes to test out complex designs.

Customization and Personalization – 3D printing allows the production of customized or personalized parts and components, which can be beneficial to manufacturers looking to create unique products tailored towards specific customer requirements. Injection molding also benefits from this advancement when 3D printers produce customized molds for plastic injection molding, enabling personalized parts and components production.

Overall, 3D printing offers several advantages that can be applied toplastic injection molding, such as greater design freedom, faster prototyping times, reduced costs for complex geometries and customization/personalization options. These advantages make 3D printing an invaluable resource for companies seeking high-quality plastic parts with improved efficiency and cost effectiveness.

IV. Advantages of Injection Molding

Though 3D printing offers several advantages over traditional manufacturing and plastic injection molding, plastic injection molding remains a valuable manufacturing method for several reasons. Here are three advantages of plastic injection molding:

High Volume Production

Injection molding is an efficient and cost-effective method for producing large numbers of identical parts in a short amount of time. This makes it ideal for mass-producing plastic parts and components.

Consistent Quality

Injection molding offers superior part quality due to the use of a fixed injection mold design that ensures uniformity throughout each part produced. Furthermore,plastic injection molding can create parts with consistent wall thickness, another essential factor for guaranteeing the consistent quality.

Durable and Longevity Parts

Injection molded parts tend to be more durable and long-lasting than their 3D-printed counterparts due to the use of metal molds that provide greater strength and rigidity.

Injection molding remains a reliable manufacturing method due to its capacity for producing high-quality parts and components with consistent quality and durability. Furthermore, plastic injection molding remains more cost-effective than 3D printing for large-volume production runs; while 3D printing may be suitable for smaller runs or prototyping, plastic injection molding remains the go-to choice when mass-producing plastic parts and components.

V. Strength of 3D Printing Compared to Injection Molding

One common question when comparing 3D printing and injection molding is whether 3D printed parts are as strong as those produced throughplastic injection molding. The answer to this inquiry depends on the specific application and material used.

Injection molded parts tend to be stronger and more durable than 3D printed ones since they are made with solid material under high pressure, creating a tightly packed structure. This results in higher densities and strengths compared to 3D printed parts which require layer-by-layer deposition of material.

However, 3D printing offers its own advantages in terms of strength and durability. For instance, this method can produce parts with enhanced strength due to fully solid infill structures; they’re stronger and more rigid than those produced through traditional injection molding processes.

Additionally, 3D printing enables the production of parts with lower thermal conductivity, leading to faster cooling times during injection molding. This reduces cycle times and boosts manufacturing efficiency.

Comparing 3D printing to injection molding, which can produce parts rapidly and efficiently, 3D printed parts may have lower dimensional accuracy and surface quality. Furthermore, 3D printed components may lack surface texture compared to those created through injection molding.

Overall, injection molding typically produces stronger and more durable parts; 3D printing offers its own advantages in terms of strength and durability, such as enhanced strength and reduced thermal conductivity. Both methods have their own benefits and drawbacks; ultimately, the choice between them comes down to your specific application and production needs.

VI. Comparison of Manufacturing Processes

Injection molding and 3D printing are two distinct manufacturing processes with their advantages and drawbacks. Here we compare the two techniques:

Injection Molding

Injection molding is the process of injecting molten material into a mold under injection molding machine extreme pressure to form metal mold into an object with a solid shape.

Materials:Injection molding is often utilized for plastic materials, but can also be employed on metals and other substances.

Accuracy:Injection molding produces highly accurate parts with low volumes and consistent wall thicknesses.

Cost:Injection molding can be costly due to the need for tooling and molds during production.

Volume:Injection molding is ideal for large-volume production runs due to its high efficiency and low cost per part.

3D Printing

Process:3D printing involves the layer-by-layer deposition of material to produce a three-dimensional object.

Materials:3D printing is typically employed for plastics, but can also be employed with metals, ceramics, and other materials.

Accuracy:3D printing can produce accurate parts, though they may lack dimensional precision and surface quality compared to injection molding.

Cost Effectiveness:3D printing can be cost-effective for small production runs, but may be more expensive than injection molding when producing larger volumes.

Volume:3D printing is ideal for small-volume production runs or prototyping due to its versatility and speedy production of customized parts.

In general, injection molding is ideal for large-volume production runs of identical parts, while 3D printing works better when producing small volumes or prototyping complex geometries and designs. The final decision on which process to use depends on your production needs and requirements such as volume, the complexity of design, material requirements, and cost considerations.

VII. Conclusion

In conclusion, both 3D printing and injection molding have their distinct advantages and drawbacks. 3D printing is a more cost effective alternative more-effective solution for small-volume production runs, prototyping, and creating complex geometries; on the other hand, injection molding works better when mass-producing identical parts in large numbers.

3D printing offers design freedom, rapid prototyping, and lower costs for small-volume production; however, it may have limitations in terms of strength and durability compared to injection molding. On the other hand, injection molding provides consistent quality, longevity, and efficient mass production but comes at a cost due to tooling and mold costs.

When selecting a manufacturing method for different production requirements, factors like volume, the complexity of design, material, and cost must all be taken into consideration. Both 3D printing and injection molding offer advantages and drawbacks; ultimately the choice between them comes down to specific production needs and requirements. By carefully selecting an appropriate manufacturing process, manufacturers can ensure high-quality injection molding services and components at cost-effective rates.