Injection molding is a commonly used manufacturing process, however there can be some downsides when it comes to product defects such as jetting.

Jetting refers to thin strings of molten material that form on the surface of products due to improper filling in molds.

To prevent this common occurrence and ensure a high quality finished pieces, we’ll take you through our helpful strategies for avoiding jetting during injection molding!

1. What is jetting in injection molding?

Injection molding is a complex process that can be prone to issues, from jetting and radiation to watermarks. Being aware of these potential problems allows for proactive steps toward quality assurance in the manufacturing sequence.

2. What Causes jetting in plastic injection molding?

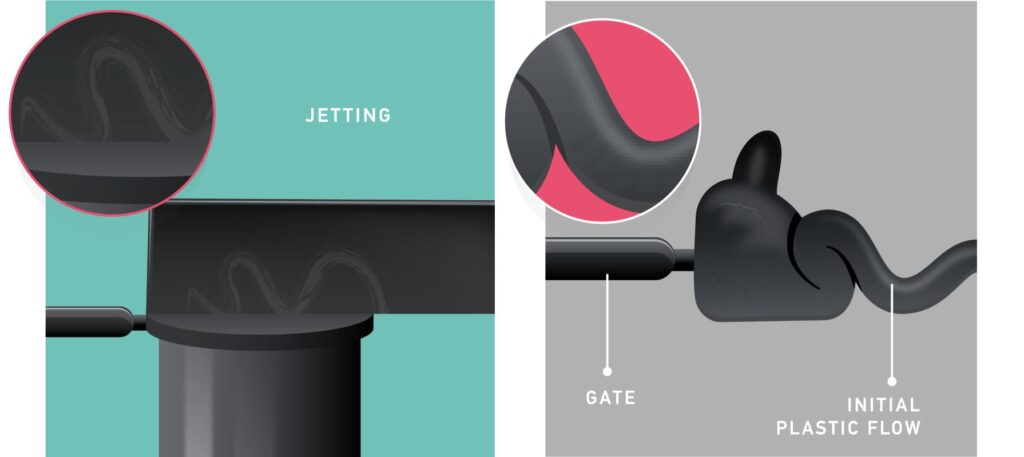

The main reason for this is that the molten polymer passes through the nozzle, runner or gate, and other flow-restricted areas at high injection speed and then enters the open area, without achieving a close fit with the mold wall thickness.

After the plastic flows into the injection mold, it will show a serpentine arrangement to form weld lines.

3. Influence of jetting on injection molded parts

Jetting can wreak havoc on plastic parts, potentially resulting in issues ranging from surface defects to weakened strength. Thus, the importance of avoiding jetting should not be overlooked!

4. How to avoid getting into injection molding?

a. Change the mold design

Usually, the root of the problem of jetting comes from improper gate design, therefore, the problem of jetting can be solved by changing the gate design to guide the contact between the melt and the wall of the injection mold.

Using overlapping gates can improve such problems, As shown in Figure 1. Overlapping gates reduce the flow velocity of the molten plastic, thereby reducing jetting effects.

The use of an ear gate or fan gate, As shown in Figure 2, can allow the melt to move smoothly from the gate to the mold cavity, to reduce the shear stress on the melt when it passes through the gate.

In addition, increasing the gate and runner size and shortening the gate length are also directions to consider.

It is important to properly design the mold to prevent jetting. The design of the mold plays a critical role in the overall quality of the finished product, and a poorly designed injection mold can result in defects such as jetting.

To avoid jetting, the mold should be designed with properly sized and spaced gates and runners, as well as adequate venting to allow air to escape from the mold.

b. Adjust the forming injection process conditions

By adjusting the filling speed curve, we can promote a smoother transition of materials at lower speeds through the gate. This will reduce jetting by increasing injection speed after materials have passed safely through.

c. Another factor that can contribute to jetting is the temperature of the molten material

Maintaining an optimal temperature for the molten material is key in avoiding jetting. Temperature sensors and other regulatory equipment can help monitor and stabilize temperatures to ensure a successful production run with no compromises on quality.

d. The flow rate of the molten material also plays a role in the formation of jetting

Seamless filling is essential for an injection mold to function properly, but this requires the precise control of flow rate.

Too fast and you’ll be faced with jetting; too slow – same result! Flow meters and other specialized equipment provide the necessary accuracy for a consistent flow that allows your material optimal fill time in order to complete its task seamlessly.

e. Another potential cause of jetting is the presence of air bubbles in the molten material

Injection molding requires a careful balance of degassing and proper venting to prevent the dreaded ‘jetting.’

Without it, air bubbles may become trapped in molten material as it is injected into an ill-prepared mould.

Using specialized equipment for degassing materials along with designing effective vents can help ensure a smooth injection process free from pesky jetting!

f. It is important to properly maintain and clean the mold to prevent jetting

To ensure optimal performance, it is essential to maintain the injection mold by regularly removing any debris that might accumulate and disrupt production.

Doing this helps keep the molten material flowing smoothly through channels for successful product formation cycles.

Cleaning agents and tools must be used appropriately in order to guarantee a clean, functioning mold during its lifetime of use.

Conclusion

Manufacturing high-quality products can be greatly improved by ensuring a properly designed injection mold, maintaining the right temperature and flow rate of molten material, removing air bubbles with degassing equipment, and regularly cleaning molds. If these steps are followed correctly it will help reduce the risk of getting defects significantly.