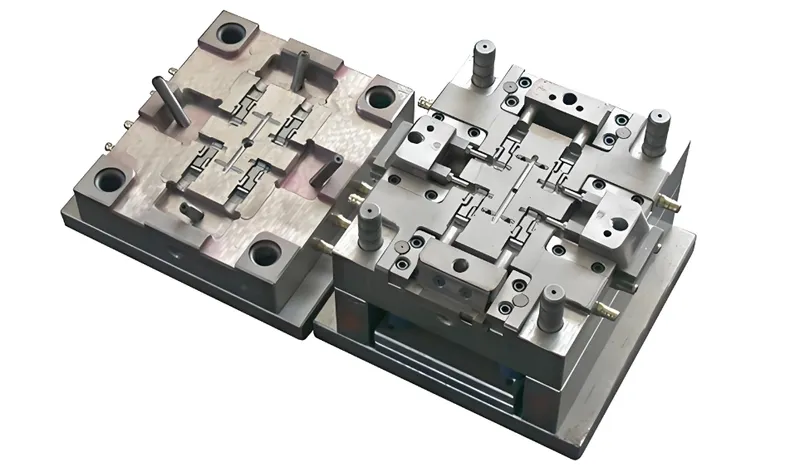

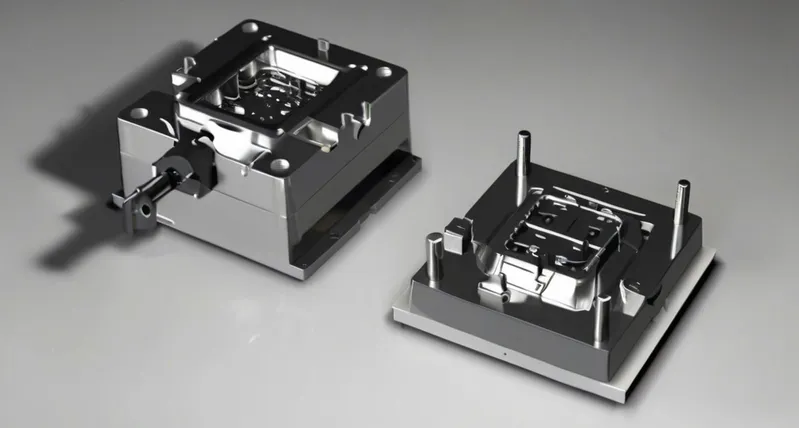

In the competitive world of plastic injection molding, multi-cavity molds are game-changers. These molds enable manufacturers to produce multiple identical parts per cycle, drastically increasing productivity and reducing per-unit costs. Whether you’re making medical components, bottle caps, or electronic housings, mastering multi-cavity mold design is essential for high-volume, precision manufacturing.

The Fundamentals of Multi-Cavity Mold Design

A multi-cavity mold contains several cavities that form identical components simultaneously. The design complexity increases exponentially with each additional cavity since balance, flow, and cooling uniformity become critical.

Key fundamentals include:

- Part geometry: Complex parts may limit cavity count due to flow imbalance risks.

- Machine capability: Clamp force, shot size, and pressure capacity must support all cavities.

- Material flow behavior: Viscosity and shrinkage affect how evenly molten plastic fills each cavity.

Advantages of Multi-Cavity Molds

-

Higher Productivity:

Producing 8 or 16 parts per cycle multiplies throughput without increasing machine count. -

Lower Unit Cost:

Although initial tooling costs are higher, mass production spreads costs efficiently across millions of parts. -

Consistent Quality:

Well-designed molds with balanced runners and cooling systems deliver identical results across all cavities.

Challenges in Designing Multi-Cavity Molds

Despite their benefits, multi-cavity molds introduce several challenges:

- Flow Imbalance: Differences in runner length or cavity resistance can cause uneven filling.

- Thermal Variations: Hot spots lead to warpage and dimensional inconsistencies.

- Maintenance Complexity: More cavities mean more surfaces to clean and inspect.

Overcoming these challenges requires precise simulation, testing, and process control.

Critical Design Considerations

1. Production Volume

High-cavity molds are ideal only for high-volume runs where cycle time and cost efficiency offset the higher tooling expense.

2. Material Selection

Polymers like PP, ABS, and PC behave differently under pressure and temperature. Simulation helps anticipate their flow and cooling characteristics.

3. Mold Base and Machine Tonnage

The machine must deliver sufficient clamping force to prevent flash and handle the cumulative injection pressure across all cavities.

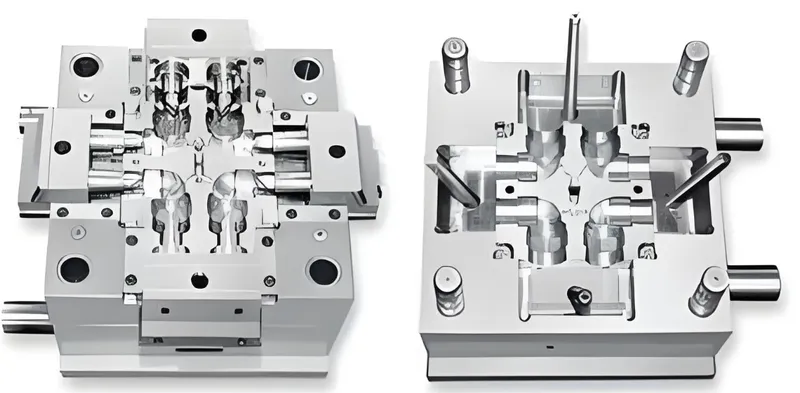

Optimizing Cavity Layout and Flow Balance

A symmetrical layout—such as 4×4 or circular configurations—helps maintain equal flow paths.

Moldflow simulations are invaluable for:

- Predicting pressure drops

- Visualizing filling patterns

- Optimizing runner geometry and gate locations

Designers often prefer balanced runner trees, where every cavity experiences the same resistance and path length.

Runner and Gate Design Optimization

The runner system distributes molten plastic from the sprue to each cavity.

- Hot runners maintain melt temperature and reduce waste.

- Cold runners are simpler but can increase cycle time.

- Gate types (edge, submarine, pinpoint) influence part aesthetics and stress distribution.

Proper runner balancing ensures that all cavities fill simultaneously and consistently.

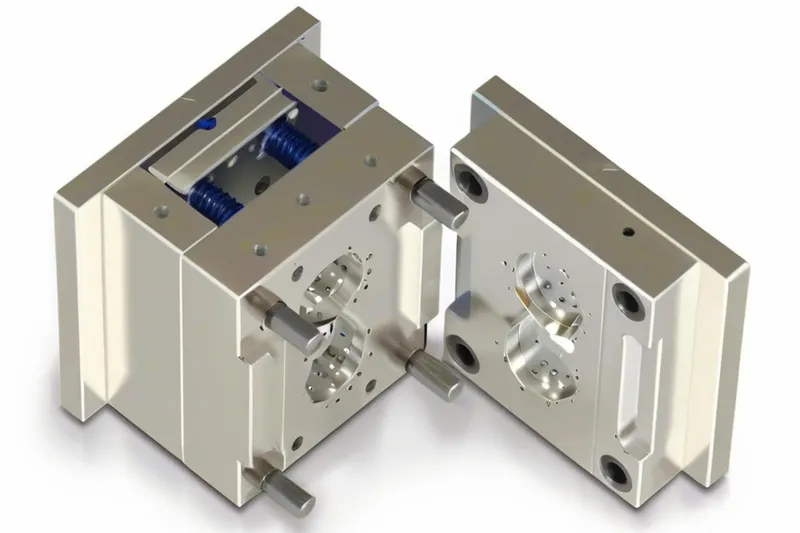

Advanced Cooling System Design

Cooling efficiency directly affects cycle time and part quality.

Modern molds employ:

- Conformal cooling channels created via 3D printing for uniform heat removal.

- Parallel circuits that prevent uneven temperature buildup.

- Thermal simulations to identify hot spots and optimize coolant flow.

Effective cooling can reduce cycle time by up to 30%, improving profitability and throughput.

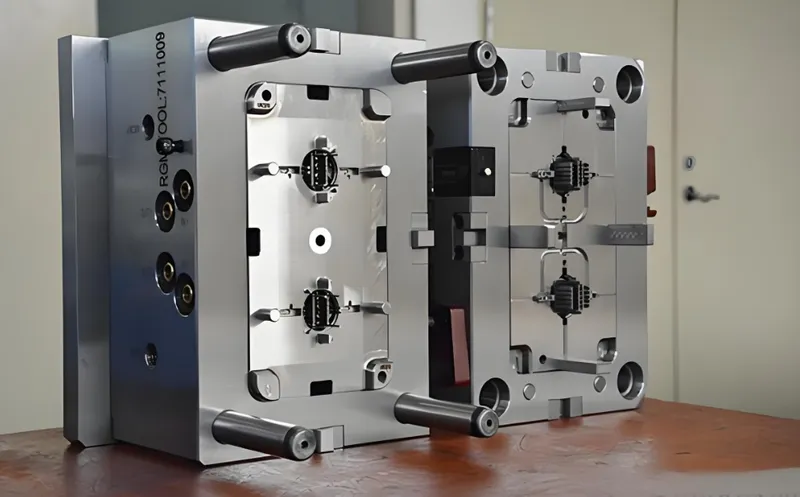

Venting and Ejection Systems

Vents allow trapped gases to escape, preventing burn marks and incomplete fills.

Ejection systems must release parts smoothly without deformation. Multi-cavity molds often use synchronized ejection plates or pneumatic ejectors to ensure precision.

Tooling Materials and Coatings

For durability, mold designers choose steels like:

- P20: For moderate-volume molds.

- H13 or S136: For high-volume, corrosion-resistant molds.

Surface treatments like DLC (Diamond-Like Carbon) coatings minimize friction and wear, extending tool life by millions of cycles.

Mold Balancing and Validation

Validation ensures consistent quality before full-scale production.

Common validation steps include:

- Short shot analysis: Observing partial fills to assess flow uniformity.

- Cavity pressure monitoring: Using sensors to confirm balanced filling.

- Cp/Cpk studies: Measuring repeatability and process capability.

Automation and Maintenance

Automation complements multi-cavity molds by enabling:

- Robotic part removal and stacking

- Real-time defect detection

- Predictive maintenance using IoT sensors

Routine inspection of cooling lines, ejector pins, and seals ensures long-term reliability.

Cost-Benefit Analysis

A 16-cavity mold may cost 4x more than a single-cavity mold, but output increases by 16x.

When production exceeds 1 million parts, the investment pays off rapidly through lower cycle time and per-unit cost.

| Factor | Single-Cavity Mold | 16-Cavity Mold |

|---|---|---|

| Cycle Time | 20 sec | 22 sec |

| Parts per Cycle | 1 | 16 |

| Cost per Part | $0.15 | $0.04 |

| ROI | — | 6 months |

Case Studies

Medical Industry (8-Cavity Mold):

A medical syringe producer cut production time by 45% using balanced hot runner systems.

Packaging Sector (16-Cavity Mold):

A bottle cap manufacturer increased annual output by 300% while maintaining ISO-certified precision.

Future Trends in Mold Design

- AI-Powered Design: Predicts cavity layout and flow dynamics autonomously.

- Additive Manufacturing: Enables 3D-printed inserts with intricate cooling paths.

- Smart Mold Monitoring: Sensors provide live feedback on temperature, pressure, and cycle counts.

These innovations are reshaping how engineers approach precision mold design.

FAQs About Multi-Cavity Mold Design

1. What’s the ideal number of cavities?

It depends on machine tonnage, material, and production goals—typically 4–64 cavities.

2. Are hot runners necessary?

Yes, for high-cavity molds, they ensure consistent temperature and minimize waste.

3. How do you balance flow between cavities?

Through symmetrical layouts and Moldflow analysis.

4. What’s the best steel for multi-cavity molds?

H13 and S136 are most common for durability and polishability.

5. How often should maintenance be done?

Every 100,000–200,000 cycles or sooner for high-wear materials.

6. What’s the future of mold design?

AI-driven optimization and real-time monitoring will define the next decade.

Conclusion

Designing multi-cavity molds is a fine balance between art, science, and economics. By integrating advanced simulation tools, precision engineering, and automation, manufacturers can unlock remarkable efficiency gains. The result is not only faster production but also improved part consistency and profitability.