Injection molding transforms electric vehicle production, boosting efficiency and performance in this rapidly growing industry.

Injection molding boosts electric vehicle manufacturing by enabling precise, high-volume production, reducing costs, enhancing durability, and supporting lightweight designs, crucial for improving energy efficiency and performance.

While this summary showcases injection molding’s role in electric vehicle production, understanding its specific applications can further optimize your processes. Dive deeper to learn how different molding techniques can elevate electric vehicle performance.

Injection molding reduces production costs in electric vehicle manufacturing.True

Injection molding allows for high-volume production of complex parts with minimal material wastage, effectively lowering overall production costs.

Injection molding is unsuitable for producing electric vehicle components.False

Injection molding is ideal for producing intricate and durable electric vehicle components, supporting industry demands for efficiency and innovation.

What is Injection Molding?

Injection molding is a widely used manufacturing process that shapes plastic into durable and complex parts for various industries.

Injection molding, used in industries like automotive and electronics, involves injecting molten plastic into molds, offering high efficiency, consistent quality, and the capability to produce complex shapes with precision.

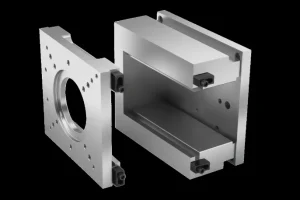

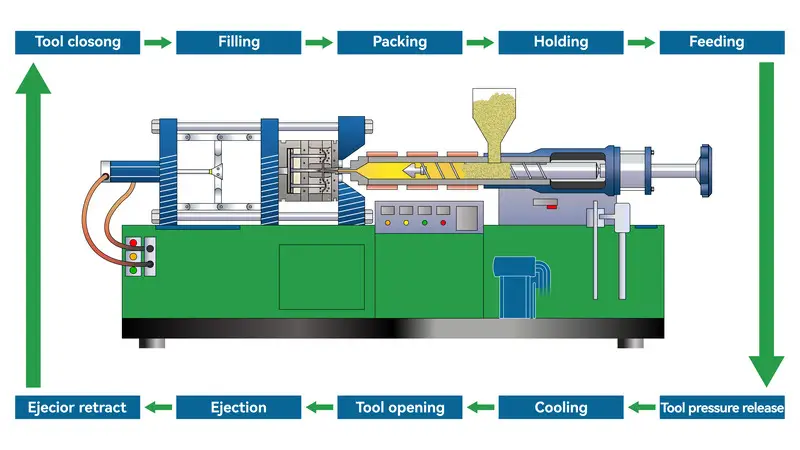

Injection molding is a manufacturing process in which melted material—usually plastic, metal, or elastomer—is injected into a mold under high pressure. The material then cools and solidifies in the mold, taking the shape of the desired part. This process is widely used for producing a high volume of parts with consistent quality and precision.

Injection molding offers several advantages, including:

-

Precision and Consistency: Parts produced through injection molding are highly accurate and can be made to tight tolerances, making it ideal for components that need to fit together seamlessly.

-

Complex Geometries: The process allows manufacturers to create parts with intricate shapes and detailed features, which would be difficult or costly to achieve with other methods.

-

Cost Efficiency: Once the mold is created, the injection molding process is highly efficient, making it suitable for mass production.

-

Material Versatility: A wide variety of materials can be used, including thermoplastics, thermosets, and even metals in specialized processes.

Given these benefits, injection molding is an attractive option for producing components in a variety of industries, including automotive.

Injection molding allows for mass production of complex parts with high precision.True

The method involves molds and controlled pressure, ensuring consistent part design and quality in high volumes.

Injection molding is unsuitable for producing small quantities of parts.False

While traditionally used for mass production, modern methods and small-scale systems have made injection molding viable for low-volume production.

What is the Role of Injection Molding in Electric Vehicles?

The electric vehicle industry1 is increasingly dependent on injection molding for producing a wide range of parts and components.s, manufacturers are turning to this technology for everything from battery components to interior panels.

Injection molding produces lightweight, durable electric vehicle parts like battery casings, enhancing design flexibility and reducing manufacturing costs while minimizing waste for sustainability.

Battery Components

One of the most critical parts of any electric vehicle is its battery. The battery pack is responsible for powering the vehicle and determining its range. Injection molding is used in the production of several components of the battery, including:

-

Battery Casings2: The outer shell of the battery pack must provide protection, structural integrity, and heat dissipation. Injection-molded plastics, such as reinforced thermoplastics, offer a lightweight yet durable solution that helps reduce the overall weight of the EV.

-

Battery Holders and Mounts: These parts secure the individual cells within the battery pack, ensuring that they stay in place during operation. Injection molding allows for precision and customization in producing parts that are both strong and lightweight.

-

Cooling Systems3: Many electric vehicle batteries require advanced cooling solutions to manage heat buildup. Injection molding is used to create the channels and housings for cooling systems that ensure the battery remains within optimal temperature ranges.

Vehicle Exterior Components

In addition to battery components, injection molding plays a vital role in producing exterior parts for EVs. With an emphasis on aerodynamic design and lightweight materials, injection molding helps create parts that are both functional and aesthetically appealing.

-

Bumpers: Injection-molded plastic bumpers are common in EVs due to their light weight, ability to absorb impact, and ease of manufacturing. These bumpers can be designed to meet safety standards while also contributing to the vehicle’s overall aesthetic.

-

Fenders and Housings: Parts like fenders, wheel arches, and light housings can be produced using injection molding to achieve complex shapes and smooth finishes, contributing to both the vehicle’s aerodynamics and visual appeal.

-

Aerodynamic Panels: Injection-molded panels are used to optimize airflow around the vehicle, reducing drag and improving energy efficiency.

Interior Components

The interior of an electric vehicle is just as important as its exterior in terms of design and functionality. Injection molding is used extensively to manufacture a variety of interior components, from dashboard panels to intricate trim pieces.

-

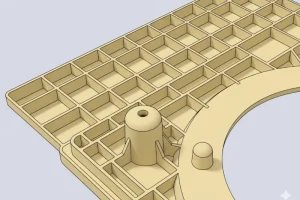

Dashboard Components4: The dashboard in an EV often houses advanced displays, buttons, and controls. Injection molding allows for the creation of these parts with precise features and smooth surfaces, improving both the look and feel of the interior.

-

Seating Components: Parts such as seat frames, trim pieces, and armrests are commonly produced through injection molding, offering a cost-effective and durable solution.

-

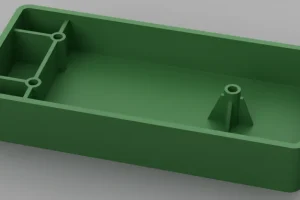

Storage Compartments: Injection molding also plays a role in creating various storage compartments and console components within the vehicle, providing practical and customizable solutions for storage needs.

Electrical and Wiring Components

Electric vehicles require a significant number of electrical components, including wiring harnesses, connectors, and insulation. Injection molding is used in the production of these parts due to its ability to produce complex shapes with high precision.

-

Connectors and Housing: Injection-molded connectors are used throughout the EV to join various electrical circuits and components. The housings for these connectors need to be durable and resistant to wear and tear.

-

Insulation Components: To ensure safety and prevent short circuits, many electrical parts within the EV need to be insulated. Injection molding is used to produce these components with high precision and consistency.

Lightweight Structural Components

One of the biggest challenges in the electric vehicle industry is minimizing weight while maintaining strength and safety standards. Injection molding helps address this challenge by enabling the use of lightweight materials without compromising the structural integrity of the vehicle.

-

Chassis Components: Some parts of the EV chassis, such as crossmembers and reinforcement beams, can be produced through injection molding with composite materials to achieve the necessary strength without adding unnecessary weight.

-

Battery Trays: The trays that hold the battery pack are critical for safety and functionality. Injection molding helps produce these parts with high precision and the ability to integrate features like cable management and cooling channels.

Injection molding decreases production costs for electric vehicles.True

By enabling mass production of complex parts with high precision and minimal waste, injection molding reduces the overall manufacturing costs of electric vehicles.

Injection molding is unsuitable for manufacturing electric vehicle components.False

Injection molding is highly suitable for EV components, offering benefits like precision, durability, and cost-efficiency, crucial for modern automotive manufacturing.

What are the Advantages of Injection Molding in Electric Vehicle Manufacturing?

Injection molding streamlines electric vehicle production, boosting efficiency and ensuring high-quality components in the automotive industry.

Injection molding enhances electric vehicle manufacturing with precision, reduced waste, and complex designs. It offers cost-effectiveness, scalability, and faster production, making it ideal for high-volume automotive parts.

-

Cost-Effective Production: Once the initial mold is created, injection molding is highly cost-efficient for mass production, making it ideal for the high-volume manufacturing required in the automotive industry.

-

High Precision and Quality Control: Injection molding provides exceptional consistency and precision, ensuring that parts meet the high standards required for automotive applications.

-

Material Flexibility: Injection molding can accommodate a wide variety of materials, including advanced thermoplastics and composites, which are essential for meeting the specific performance and safety requirements of EVs.

-

Sustainability: Injection molding can help reduce waste, as it produces parts with minimal material leftover. Additionally, many EV manufacturers are using recyclable and sustainable materials in their injection-molded components, contributing to the overall eco-friendliness of electric vehicles5.

Injection molding accelerates production in electric vehicle manufacturing.True

Injection molding allows for mass production of components with consistent quality, reducing the overall manufacturing time.

Injection molding has limited application in electric vehicle manufacturing.False

Injection molding is widely used in EV manufacturing for producing a variety of complex and precise plastic components.

What are the Challenges of Injection Molding in Electric Vehicle Manufacturing?

Injection molding is crucial in electric vehicle (EV) manufacturing, yet it presents challenges such as material selection, precision demands, and maintaining efficiency in high-volume production.

In EV manufacturing, injection molding faces challenges in choosing lightweight materials, achieving precision in complex parts, controlling costs, and maintaining high-quality production at scale, crucial for optimizing EV performance and sustainability.

-

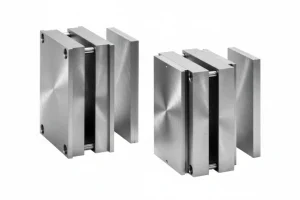

Initial Tooling Costs6: The creation of molds for injection molding can be expensive, particularly for complex or highly customized parts. However, these costs are amortized over large production runs.

-

Material Selection7: Choosing the right material for injection-molded components is crucial, as the material must meet performance, safety, and environmental standards. Advances in material science are addressing this challenge, but it remains a consideration for manufacturers.

-

Complexity of Design8: While injection molding can produce highly complex geometries, the design of the mold must be carefully considered to avoid defects and ensure efficient production.

Injection molding allows for precise manufacturing of complex EV parts.True

The process accommodates intricate designs and tight tolerances, ideal for making detailed EV components like battery casings and connectors.

Injection molding is always unsuitable for EV components.False

While there are challenges, injection molding remains a viable method for producing numerous EV parts, especially when optimized for specific materials and geometries.

What is the Future of Injection Molding in the Electric Vehicle Industry?

Injection molding is poised to play a critical role in the evolution of the electric vehicle industry, enhancing production efficiency and enabling the creation of lightweight, high-performance components.

Injection molding in the EV industry enables the production of complex, lightweight parts, enhancing efficiency and sustainability. It reduces material waste, lowers costs, and provides high precision, benefiting EV manufacturers significantly.

As the electric vehicle market continues to grow, the role of injection molding in EV manufacturing will only become more important. Advancements in material science, mold design, and automation technologies will further enhance the capabilities of injection molding, making it even more effective in producing the lightweight, durable, and sustainable components required for modern EVs.

Moreover, as the push for sustainable transportation accelerates, injection molding will continue to contribute to the development of eco-friendly vehicles. The use of recyclable materials and energy-efficient production methods will align with the EV industry’s broader goals of reducing its environmental footprint.

Injection molding reduces production costs in the EV industry.True

The process minimizes material wastage and lowers manufacturing costs by enabling efficient mass production of complex parts.

Injection molding limits design possibilities for EV components.False

Advancements in injection molding allow for complex and innovative designs, providing flexibility and creativity in EV component manufacturing.

Conclusion

Injection molding9 is playing a key role in the development and production of electric vehicles, offering benefits such as cost efficiency, precision, and material versatility. From battery components to interior trim pieces, injection molding is enabling manufacturers to produce high-quality, lightweight, and durable parts that meet the demands of the growing EV market.

As the industry continues to evolve, the importance of this manufacturing technology will only increase, contributing to the future of electric vehicles and sustainable transportation.

-

Explore how injection molding is revolutionizing the electric vehicle industry with innovative parts and components. ↩

-

Learn about the advantages of injection molded battery casings, which enhance performance and safety in EVs. ↩

-

Learn about the critical role of cooling systems in EV batteries to ensure optimal performance and safety. ↩

-

Discover how dashboard components enhance the user experience in EVs through advanced design and technology. ↩

-

Understanding the components of electric vehicles can provide insights into their design and functionality, crucial for industry enthusiasts. ↩

-

Understanding initial tooling costs is crucial for manufacturers to budget effectively and optimize production processes. ↩

-

Material selection is vital for performance and safety in EVs; exploring this can enhance your knowledge of manufacturing standards. ↩

-

Exploring design complexities can help manufacturers avoid defects and improve production efficiency in the EV sector. ↩

-

Learn about Injection Molding: A Comprehensive Guide : Injection molding is a manufacturing process where molten plastic is injected into a mold to create parts with high accuracy and repeatability. ↩