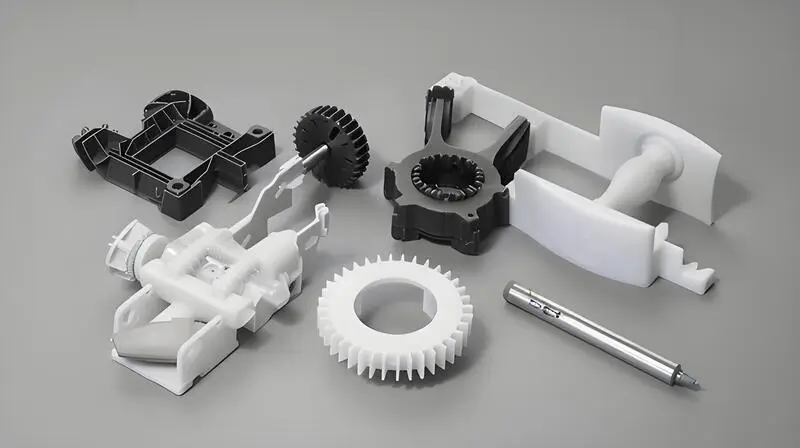

Acetal injection molding offers precision and durability, making it an essential process for manufacturing high-performance plastic components.

Acetal injection molding is ideal for precision parts, offering strength, wear resistance, low friction, and dimensional stability, making it popular in automotive, consumer electronics, and industrial sectors.

While acetal injection molding presents clear benefits, understanding the material properties and processing parameters is crucial for optimal results. Dive deeper to learn how this technique can elevate your manufacturing capabilities.

Acetal is ideal for precision parts due to its dimensional stability.True

Acetal's low moisture absorption and thermal expansion ensure consistent part dimensions over time.

Acetal is unsuitable for injection molding due to high brittleness.False

Acetal offers a balance of strength and resilience, making it suitable for various durable plastic components.

What are the Material Properties of Acetal?

Acetal, also known as polyoxymethylene (POM), is a versatile engineering thermoplastic renowned for its high strength, stiffness, and excellent dimensional stability across various industrial applications.

Acetal’s high wear resistance, low friction, and excellent chemical resistance make it ideal for gears and bearings. It maintains performance between -40°C to 120°C, ensuring mechanical stability and durability.

Physical Properties

-

High Crystallinity: Acetal is a material with a high degree of crystallinity, so it has considerable hardness and stiffness.

-

Low Moisture Absorption: Acetal has very low hygroscopicity, and the performance of the material does not change even in a closed environment with high humidity.

-

High Wear Resistancen1: Acetal has excellent wear resistance and good self-lubricating properties, and the material is very suitable for the production of parts that require high durability.

-

Good Dimensional Stability2: Acetal maintains good dimensional stability over a wide temperature range.

Chemical Properties

- Chemical Resistance3:Acetal has excellent stability with regard to many chemicals such as oils, fuels, alcohols, and dilute acids.

- Weather Resistance: Acetal has fairly high weather resistance and is therefore suitable for outdoor use, but prolonged exposure to UV rays may reduce outdoor performance.

Mechanical Properties

-

High Strength: Acetal has high tensile and impact strength.

-

High Rigidity: This attribute is as a result of its highly crystalline nature of Acetal, making it have a very high rigidity.

-

Low Friction Coefficient: The self-lubricating properties result in excellent performance in friction applications.

Acetal is suitable for high-temperature applications above 150°C.False

Acetal is typically used within a temperature range of -40°C to 120°C; it is not suitable for applications requiring higher temperature performance.

Acetal offers low water absorption.True

Acetal has low water absorption, which contributes to its dimensional stability and consistent performance in humid environments.

What are the Advantages and Disadvantages of Acetal Materials?

Acetal materials are widely used in engineering applications for their exceptional strength, low friction, and high dimensional stability.

Acetal offers excellent mechanical properties, reduced wear, and high resistance to moisture and chemicals, but it has drawbacks like thermal expansion and limited acid resistance. It’s used in automotive, plumbing, and electronics industries.

Advantages

-

Excellent Mechanical Properties4: Acetal materials have excellent mechanical strength and hardness, such as tensile strength, stiffness, etc., making them suitable for parts and gadgets that require high strength and rigidity performance.

-

Good Dimensional Stability5: Acetal products can maintain their dimensional stability over a wide temperature range, regardless of whether the temperature is rising or falling, acetal products rarely expand or contract due to temperature changes, which is very beneficial for precision mechanical parts.

-

High Wear Resistance6: Acetal features better wear resistance; therefore, is applied to parts such as bearings and gears.

-

Good Chemical Stability7:Acetal provides resistance to many chemicals such as some solvents and fuels, making it suitable for environments where chemical stability is critical.

-

Ease of Processing8: Acetal material is easy to process and shape, and has good injection molding and machining effects, so it can be mass-produced to improve production efficiency and provide complexity to the final product.

Disadvantages

-

Brittleness: Acetal may also become slightly less resilient or even brittle at low operational temperatures, potentially affecting its performance in cold conditions.

-

Thermal Stability: Acetal exhibits good properties in the normal operating temperature range, but its heat resistance is not as good as other engineering plastics and its thermal stability is lower, making it unsuitable for high temperature applications.

-

Higher Cost: While using Acetal, the raw material cost is relatively higher than some of the traditionally used plastics and could thus lead to higher manufacturing costs.

Acetal materials offer high tensile strength, making them ideal for engineering applications.True

Acetal's molecular structure provides excellent mechanical properties, ensuring durable and robust components.

Acetal materials are resistant to all chemical exposures.False

Although acetal resists many chemicals, it is vulnerable to strong acids, necessitating careful consideration of its application environment.

What are the Injection Molding Conditions of Acetal?

Understanding acetal injection molding conditions is key to optimizing product quality and efficiency in industries like automotive and consumer goods manufacturing.

Acetal injection molding needs a melt temperature of 190-230°C and mold temperature of 80-120°C for optimal flow and stability, minimizing defects. Acetal is preferred for its strength and low friction.

Material Preparation

Before injection molding, acetal needs to be dried. However, it should be noted that acetal itself is not highly hygroscopic, but if it is stored in a high humidity area, it will still absorb a small amount of moisture, so it must be dried. Typically, the drying temperature is selected between 80-100°C and the drying time is 2-4 hours.

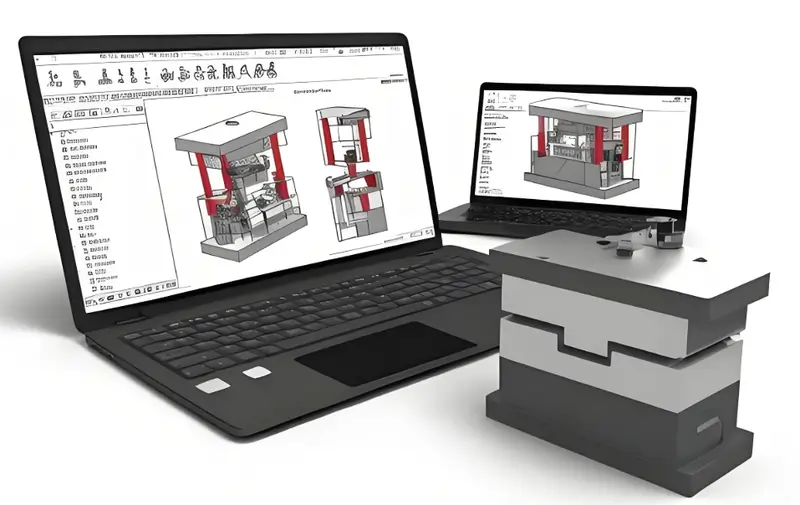

Injection Molding Machine Selection

The choice of injection molding machine should be based on the size and shape of the final product. Acetal injection molding usually selects injection molding machines with screw diameters between 30-150mm. The screw compression ratio should be between 2.5:1 and 3.0:1 to ensure that the acetal is fully mixed and plasticized during melting and injection.

Mold Design

Mold design proves to be very significant when it comes to Acetal injection molding. Key considerations include:

-

Mold Temperature: controlled temperatures also have influence on the quality of the final products in the mold. Usually, it should be within the range of between 80-120°C to allow adequate flow and cooling of Acetal during molding.

-

Gate Design: Flood runner gates or direct/side gates it is desirable for the molten Acetal to fill the mold cavity as quickly as possible.

-

Ventilation System: During molding, Acetal releases a small amount of gas therefore a good ventilation system is best to eliminate formation of bubbles or voids in the finished product.

Injection Molding Process Parameters

Process parameters mean that setting of specific factors as a part of the process directly affects the quality of the product. Common parameters and their recommended ranges are:

-

Injection Temperature9:The melting temperature of Acetal is between 180-220°C and the common injection temperature are between 190-210°C.

-

Injection Pressure: Common injection pressure is 70-120 MPa with a constant adjustment depending on the product, its density, and thickness of the part.

-

Injection Speed: Injection speed must not be very high and must be just enough to let the molten Acetal flow within the mould cavity. Predominantly a medium speed is chosen.

-

Holding Pressure and Cooling Time: Pressures and cooling time normally takes depend on size and thickness of the product. Holding time usually ranges from 10-30 seconds while cooling time is for 20-60 seconds.

Acetal injection molding requires very high mold temperatures.False

Acetal mold temperatures range from 80-120°C, which is moderate, ensuring proper material flow without excessive energy consumption.

Acetal offers excellent thermal stability in molded parts.True

Acetal retains its strength and dimensional stability under heat, making it ideal for high-performance applications.

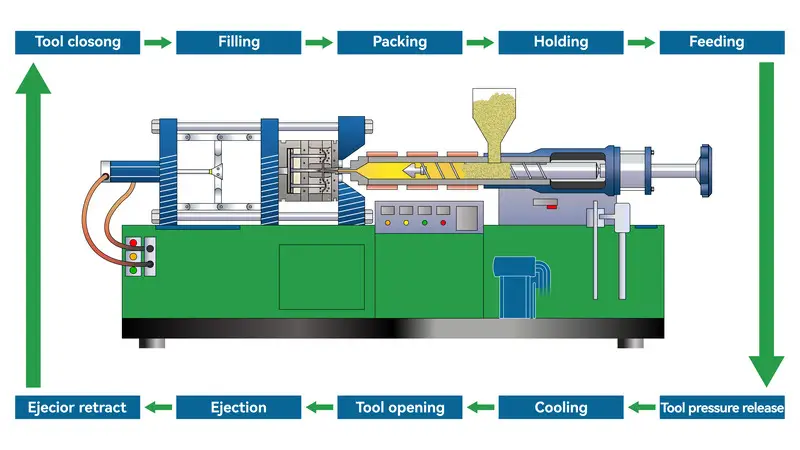

What is the Injection Molding Process of Acetal?

The injection molding process of acetal is crucial for producing high-quality components, given its durability and precision in various applications.

Acetal injection molding is a process of heating and injecting acetal resin into molds to create durable parts, widely used in automotive and consumer goods industries for its excellent mechanical properties.

-

Mold Assembly: Make sure that mold is clean and set appropriately on the injection molding machine. Assure yourself that the mold’s vents and method of cooling are proper.

-

Material Drying10: On the process of using materials for appropriate products, one has to place Acetal in dryer to eliminate excess moisture that is in Acetal and make the level of moisture to be reasonable.

-

Setting Process Parameters: Depending on the requirement of the product one has to set the injection temperature, injection pressure, injection speed, holding time and cooling time.

-

Preforming and Injection: The injection molding machine heating system includes melting the polyoxymethylene material and injecting it into the mold to complete. The injection speed should be slow to eliminate quality problems on the surface of the product.

-

Holding Pressure and Cooling: The necessary pressure must be applied during the holding pressure stage to ensure that the final product fully covers the design of the specific product. The cooling time depends on the size of the product and the wall thickness of the specific product.

-

Demolding and Extraction: After cooling, open the mold and take out the finished product. Check the product quality. If there are defects, adjust the process parameters.

-

Waste Handling: Disposal of waste material which comes with the injection molding process with recycling mainly getting used to decrease wastage.

Acetal provides superior dimensional stability in injection molding.True

Acetal has low water absorption and high stiffness, ensuring precise and stable dimensions in molded parts.

Acetal is the cheapest material for injection molding.False

Although acetal offers excellent properties, it is generally more expensive than other plastics like polypropylene, making it suitable for specific high-performance applications.

What are the Common Problems and Solutions in Acetal Injection Molding?

Acetal injection molding presents unique challenges, but addressing them effectively enhances product quality and manufacturing efficiency.

Acetal injection molding issues like warping and shrinkage can be resolved by optimizing mold design, processing parameters, and material drying, leading to improved part consistency and fewer defects.

Shrinkage Control

In terms of shrinkage, acetal has a slightly higher shrinkage rate, ranging from 1.8-2.5%. To ensure the best dimensional accuracy of the product, it is necessary to ensure that there is enough shrinkage allowance11 in the mold design and maintain a uniform mold temperature. It may be necessary to adjust the injection pressure, holding time, and cooling time according to actual production conditions to correct shrinkage and deformation problems.

Warping and Deformation

Warpage and deformation are common problems in polyoxymethylene12 injection molding, and they are usually caused by differences in cooling speed or large internal stress. Optimize the cooling system in the mold design to ensure that all mold parts are cooled evenly. Adjust the injection speed and holding pressure to reduce internal stress.

Surface Defects

Some surface defects that may occur in acetal products include silver streaks13, bubbles, and burn marks. Silver streaks are often caused by moisture and must be dried before production. Bubble problems can be caused by insufficient ventilation or too fast an injection speed and can be resolved by checking the ventilation system or reducing the injection speed as needed. Burn marks are caused by high melt temperatures or long residence times of the part; adjust the injection temperature and speed accordingly.

Internal Stress Issues

Internal stress during molding can cause cracking and deformation of the product. This problem can be alleviated by slowing down the cooling rate by lowering the mold and injection temperature. Increase the holding time to allow the melt to fully solidify in the mold and minimize internal stress14. Optimize the gate location and its size to ensure uniform melt flow in the mold cavity.

Proper mold design reduces acetal warping issues.True

A well-designed mold ensures even cooling and minimizes internal stresses, which can lead to warping in acetal parts.

Acetal is always easy to mold regardless of conditions.False

Acetal can present issues like shrinkage and sensitivity to moisture, requiring careful control of molding conditions for optimal results.

What are the Practical Applications of Acetal ?

Acetal, a versatile thermoplastic, is widely utilized for its strength, durability, and excellent dimensional stability in various applications.

Acetal is used in automotive, electronics, and medical devices for gears, bearings, and fittings due to its low friction, high wear resistance, durability, and precision.

Automotive Industry

Acetal is commonly used in fuel system components, headlamp housings, door lock systems, and seat adjusters in automobiles. These components require high strength and wear resistance, so acetal is an ideal material.

-

Fuel System Parts: Acetal is applied widely in automotive fuel system components such as fuel pumps, fuel lines, and fuel filters, which necessitate high temperature stability, good resistance to corrosion, and superior mechanical characteristics.

-

Headlamp Housings: Application of Headlamp housings require high transparency, UV stability, and weathering resistance all of which can be provided by Acetal.

-

Seat Adjusters: Acetal is used in mechanical components such as gears, levers and slides in seat adjusters, which require high strength, low friction and wear resistance.

Electronics and Electrical Equipment

In electronics, Acetal is employed in connectors, switch parts along with the sensor enclosures. Its heat resistance and insulating properties make it important for electronic products.

Medical Devices

Acetal has good biocompatibility15 and chemical resistance, therefore, acetal can be used to manufacture medical devices such as surgical instruments, syringes, and dental-related products.

Household Appliances

Acetal is also widely applied in home apparatuses and electronics including washing machine accessories, appliances for food processing, and microwave oven rotary tables. Its strength and end-use characteristic are very important to this sector.

Acetal is used to produce low-friction gears.True

Acetal's low coefficient of friction makes it ideal for gears requiring smooth operation and minimal wear.

Acetal is too fragile for automotive applications.False

Acetal's high strength and resistance make it suitable for various automotive components, including fuel systems and interior features.

Conclusion

Acetal plastics which are also referred to as polyoxymethylene (POM) are the semi-crystalline engineering thermoplastic with high-quality mechanical properties, ideal for injection molding. Acetal polymers come in two primary forms: they are; homopolymer acetal and copolymer acetal. Both kinds of acetal plastic material have a high tendency to be utilized while the manufacturing of mechanical commodities because of the firmness, stiffness & less friction property.

Self-reinforcing homopolymer acetal has a somewhat higher tensile strength and the chemical and heat resistant acetal copolymers. The injection molding ]manufacturing process for acetal resin is accurately molded and creates highly efficient mechanical gears and other highly accurate parts. Moreover, acetal plastics are quite immune to the attack of many chemicals such as ethylene oxide making the material more suitable for use in the industrial markets.

This guide covers the material properties, advantages and disadvantages, molding conditions, and common issues in Acetal injection molding. By properly preparing materials, selecting appropriate molding machines16, designing molds effectively, and controlling process parameters, product quality can be significantly improved and common processing issues can be resolved.

-

Understanding the benefits of high wear resistance can help you appreciate why Acetal is ideal for durable parts. ↩

-

Exploring dimensional stability will reveal why Acetal is preferred for precision mechanical parts. ↩

-

Learning about chemical resistance can highlight Acetal’s suitability for harsh environments and applications. ↩

-

Understanding the mechanical properties of Acetal can help you appreciate its applications in various industries, enhancing your knowledge of material science. ↩

-

Exploring dimensional stability in Acetal can reveal its advantages in precision engineering, crucial for high-performance applications. ↩

-

Learning about wear resistance in Acetal can inform you about its suitability for demanding mechanical parts, enhancing your material selection skills. ↩

-

Understanding the chemical stability of Acetal can help you choose the right materials for your projects, ensuring durability and performance. ↩

-

Exploring the ease of processing Acetal can provide insights into efficient manufacturing techniques and cost-saving strategies. ↩

-

Learning about the ideal injection temperature for Acetal can enhance your molding processes, leading to better product quality. ↩

-

Learn effective drying techniques for Acetal to eliminate moisture, which is crucial for achieving optimal molding results. ↩

-

Discover methods to accurately calculate shrinkage allowance, ensuring better dimensional accuracy in your mold designs. ↩

-

Learn about polyoxymethylene’s unique properties and its various applications in industries, enhancing your knowledge of this material. ↩

-

Understanding the causes of silver streaks can help improve production quality and reduce defects in acetal products. ↩

-

Learning about internal stress management can enhance product durability and performance in acetal manufacturing. ↩

-

Exploring acetal’s biocompatibility can provide insights into its safety and effectiveness in medical applications. ↩

-

Learn about Injection Molding Machines a Comprehensive Guide:An injection molding machine is a piece of equipment that is widely used in industrial production. ↩