Injection molding optimization is key to improving manufacturing efficiency, reducing costs, and ensuring high-quality output across diverse industries.

Optimizing injection molding cycle time involves adjusting temperature, pressure, and cooling time to reduce production duration and costs while improving quality, using advanced technologies, materials, and machinery.

While this summary outlines the basics of cycle time optimization, delving into specific techniques and technologies can significantly enhance your production process. Discover how targeted adjustments can lead to substantial improvements in your facility’s output efficiency.

Optimizing cycle time reduces manufacturing costs and boosts efficiency.True

By decreasing cycle time, manufacturers can produce more parts in less time, effectively lowering per-unit costs.

All cycle time optimizations require expensive equipment upgrades.False

Many optimizations can be achieved through process adjustments and parameter tuning without significant investment in new equipment.

What is the Concept of Injection Molding Machine Cycle Time?

Injection molding machine cycle time is a crucial factor in manufacturing efficiency, impacting both production speed and cost-effectiveness across various industries.

Cycle time in injection molding encompasses injection, cooling, and ejection phases. Reducing it boosts efficiency and cuts costs, influenced by equipment settings, material choice, and mold design.

Cycle time for an injection molding machine is the time it takes for the machine to complete each injection molding process, which typically includes injection, holding pressure, cooling, and other steps. It directly affects the production efficiency and product quality of the machine. So, adjusting the cycle time1 of an injection molding machine is an important part of optimizing production.

Reducing the cycle time always improves the quality of the final product.False

Reducing cycle time might increase efficiency, but it doesn't always enhance product quality, which depends on other process parameters too.

Cycle time reduction leads to lower production costs.True

Efficient cycle times increase production rates, thus reducing labor and overhead costs per part.

What are the Steps of the Injection Molding Cycle Times?

Injection molding cycle times determine the efficiency and productivity of manufacturing, impacting everything from production speed to the quality of the finished product.

Injection molding cycle times include filling, packing, cooling, and ejection. Optimizing these steps is essential for enhancing efficiency and cutting manufacturing costs.

-

Injection stage: The heated material is pushed into the mold and cavity by pressure.

-

Filling stage:When all the material of a cycle is pushed into the mold and continuous pressure is applied to make sure that the cavity is completely filled and to solve the shrinkage that may happen when the material efficient cooling.

-

Cooling stage: When the material cools into a solid form and is ready to be pushed out.Each of these steps has potential efficiencies that can reduce overall cycle time. The cooling phase is by far the most time-consuming step in the injection molding process, so a significant impact can be made in reducing these times.

Injection molding cycle times include the cooling phase.True

The cooling phase allows the molded part to solidify and be capable of being ejected without deformation or defects.

Reducing injection molding cycle times always compromises product quality.False

Careful optimization of cycle times can maintain or even enhance product quality while increasing efficiency.

What are the Parameters to Consider When Optimizing Molding Cycle Time?

Optimizing molding cycle time is essential for maximizing efficiency and reducing costs in the injection molding process across industries.

Optimizing molding cycle time hinges on mold temperature, cooling rate, material choice, and equipment efficiency, affecting production speed, quality, and costs. Adjustments in these areas can greatly enhance cycle efficiency.

Cooling Time

One of the easiest ways to optimize your cycle is cooling time. In most molding scenarios, cooling time is set to be 1.5 to 2 seconds longer than screw rotation time. It is important to note that some situations may require a longer cooling cycle (such as dimensional requirements or part bonding), but as a general rule, screw rotation time determines cooling time.

Holding Time

Another big thing that will help you maximize your cycle time is holding time. The best way to do this is through a gate seal study2. Gate seal is the amount of time it takes to cool the runner tip to a stationary state. This keeps plastic from leaking out of the runner, which can cause molding inconsistencies.

Doing a gate seal study is easy. Once you have your decoupled process set up, set your hold time way higher than you normally would for the material and part size you’re working with. While you’re running, reduce your hold time and weigh each part as it relates to variation. If you see the weight go down, when the weight goes down, increase your hold time by 1 second and you’re done.

Fill Time

Another thing that affects cycle time is fill time. Fill time is how fast or slow the material goes into the mold. Fill time is controlled by injection speed. Fill time is also limited by the type of material and the complexity of the mold. The goal of optimizing fill time is to shoot the material as fast as possible without affecting the looks and function of the part you are making.

Melt Temperature

When you’re setting up the process, using the lowest temperature can help reduce cooling time3, which can help reduce cycle time. It’s important to note that each processing method is different, so higher viscosity at lower melt temperatures can cause defects. Start your process at the lower end of the melt window and as you make adjustments, increase the temperature until you achieve process stability.

Mold Temperature

Mold temperature also affects cooling time. When setting mold temperature4, start at the low end of the normal processing range recommended by the material supplier. Higher temperatures may be needed to improve appearance or even to eject the part. Mold temperature can also affect dimensional properties, so this must be considered.

Back Pressure

The higher the back pressure, the longer the screw will rotate, which affects the minimum cooling time. Use enough back pressure to achieve melt consistency, but keep it as low as possible to reduce screw rotation time.

Mold Opening/Closing

Maximize mold open and close speeds to minimize mold open time. Note that mold separation and mold close speeds are affected by the complexity of slides, flare pins, etc., so make sure you have safe mold operation first when setting up the mold.

Also, watch for low pressure closing – you want to keep it as low as possible for mold protection, but remember that with speed/pressure settings too low, they can increase overall cycle time. Again: safety and mold protection come first, then optimization.

Ejection

If you don’t have your ejection set up right, it can really slow down your cycle. When you’re setting up your ejection, only use as much stroke as you need to get the part out of the mold without sticking it in the mold.

Ejection speed and pressure are also important for faster ejection times, but when you start increasing your speed/pressure settings, watch out for pin pushing or cracking. Generally, minimum pressure and maximum speed will give you the best results.

Robotics

Robotic function can also affect the cycle. There are two main effects that can be optimized. First, the robot needs to get in and out of the mold quickly to prevent the mold open time from increasing. Second: The robot needs to be in position waiting for the mold to open. When possible, set the robot\’s waiting position on the Y axis as low as possible to shorten the extraction time.

Adjusting mold temperature can reduce cycle time.True

Proper mold temperature control leads to faster cooling and solidification, directly decreasing the cycle time.

Cycle time optimization is irrelevant to product quality.False

Optimal cycle times help maintain consistent product quality by ensuring precise material cooling and shaping.

How to Optimize the Cycle time of Injection Molding?

Streamlining cycle time in injection molding is crucial for enhancing productivity and reducing manufacturing costs. Efficient cycle time management leads to faster production runs and improved output quality.

Optimizing injection molding cycle time through temperature control, mold design, and automation enhances efficiency and reduces costs, benefiting industries such as automotive and consumer goods manufacturing.

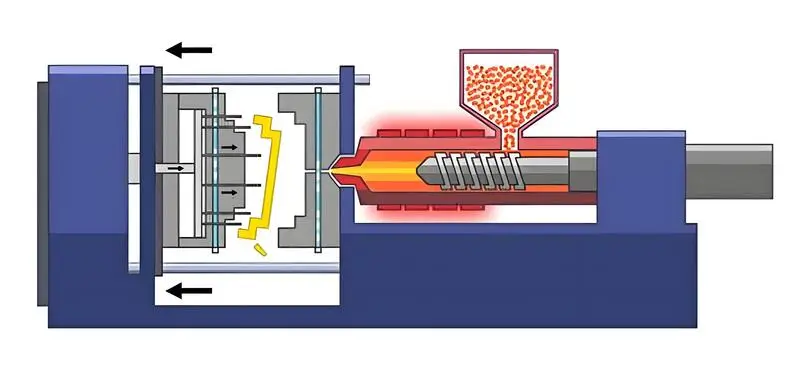

If you want to save money on making plastic parts, you need to make your injection molding machine5 run faster. When it runs faster, it makes more parts at the same time and uses the same amount of electricity. Here are some ways to make your injection molding machine run faster.

Injection Molding Machine

Maintain the Injection Molding Machine

Check and maintain the injection molding machine itself. Regularly check if there are any defects or damages in the structure of the injection molding machine, and repair them in time to avoid failures during the production process.

The injection system of the injection molding machine must be kept unobstructed to ensure that the melt can enter the mold quickly and stably. In addition, regular cleaning and lubrication of mechanical parts can reduce mechanical failures and avoid production delays caused by failures.

To improve injection molding cycle time and production efficiency, you need to use advanced injection molding machine equipment and technology. The selection and use of large injection molding machines directly affect the efficiency and effect of the injection molding process.

Advanced injection molding machines are equipped with high-performance motors and hydraulic systems, which have faster response speed and higher precision, so that the injection molding cycle time is faster and the production efficiency is higher.

At the same time, the use of automated and intelligent control systems can achieve precise parameter adjustment and monitoring, improve the stability and consistency of the injection molding process.

Fine-Tuning the Injection Molding Machine

Older injection molding machines can have performance problems, like inconsistent injection pressure and speed. This means it takes longer to inject the same amount of material as a new machine or a better-maintained machine. Pressure or filling time errors can also cause parts to be scrapped, which increases overall production time (and makes for longer effective cycle times).

Injection molding expert. Good injection molding is more than just setting up the machine and letting it run. An injection molding expert will be able to identify subtle adjustments to variables such as injection speed, buffer, holding time, etc., which can have a big impact on part quality and cycle time.

Using High-Speed injection Molding Machines

Injection molding machines go through the following steps: melting plastic, injection, mold opening, mold closing, and demolding. The function of the injection molding machine itself is one of the main reasons that affect the injection molding cycle time. High-speed injection molding machines have many advantages in terms of speed.

Make sure the mold structure is simple and easy to process, in other words, make the mold design as difficult as possible. Most molds can be designed in different ways, and there are many ways to demold. Simplified mold design6 can reduce the cycle time of injection molding.

Mold

Consider Mold Design

Besides the material, the mold is also a big factor in cooling time. A good mold will let water and air (two common coolants) flow through it well. The cooling channels7 should be kept clean and clear so the parts cool as fast and evenly as possible. If the parts cool unevenly, they will warp and be scrapped.

When designing and manufacturing molds, the cooling channels should be reasonably arranged according to current production needs to ensure sufficient cooling water flow, minimize mold surface adhesion, ensure the smoothness of the mold surface, etc.

Adjust Mold Temperature

Changing the mold temperature can have a big impact on cycle time. Lowering the mold temperature can increase the cooling time and increase the cycle time. You can control the mold temperature by adjusting the temperature of the heater.

Mold Design Optimization

Optimizing mold design is a great way to cut down on molding time. The runner design should be as simple as possible to shorten the flow path and speed up filling. Also, a good cooling system design can speed up the cooling of the plastic part. But be careful, if you cool too much, it will take longer to cool, so you have to balance cooling efficiency and cycle time.

Design the mold structure, cooling system, and runner layout in a way that reduces cooling time and plastic flow resistance, thus shortening the cycle.

Material

Choose the Right Plastic Material

Some materials will have a higher fill pressure rating or a higher flow rate. This means they can get into the mold faster and fill all the cavities faster. Material selection is often overlooked or dismissed, but make sure to consider whether different resin properties are appropriate for your parts.

Picking the right plastic material8 can make a big difference in the cycle. When you’re making the part, you want to use good raw materials and pick different materials for different production conditions. Materials with low melting points and high fluidity can fill the mold faster and cool and solidify faster, so you can make the part faster.

Use Resins That are Easy to Flow and Quickly Solidify

Using resins that flow easily and solidify quickly can greatly reduce filling and cooling times. For example, resins with low viscosity can fill the mold faster, while resins with high thermal conductivity can help speed up the cooling process. However, you must also consider the requirements of the finished product, such as strength, temperature resistance, and chemical resistance, when selecting materials.

Injection Molding Process

Optimizing the Injection Molding Process

To shorten the cycle time during production, you can analyze and adjust different process parameters. For example, you can adjust the injection speed, injection pressure, and holding time.

To improve the injection molding cycle time and production efficiency, you need to optimize the injection molding process9. By designing and optimizing the injection molding process, you can reduce the injection molding cycle time and improve production efficiency.

The key injection molding process parameters10 include injection speed, injection pressure, cooling time, etc. By adjusting and optimizing these parameters, you can achieve the best injection molding effect and cycle time. In addition, the reasonable selection of injection molding materials and mold design also have an important impact on the injection molding cycle time and production efficiency.

Adjustment of Process Parameters for Injection Molding

Changing the process parameters for injection molding is a good way to make the molding cycle shorter. If you increase the injection speed, you can fill the mold faster, but if you go too fast, you might get flash or short shots, so you have to find the right balance.

If you increase the mold temperature and the barrel temperature, the melt will flow better, but if you go too high, you might degrade the material or put too much internal stress in the part, which will affect the quality. Also, if you optimize the hold time and the hold pressure, you can make sure the part is fully solidified and you can get rid of any unnecessary delays.

Wall Thickness

The Wall Thickness is Kept at the Minimum Thickness

This minimalist approach to part design means that less material needs to be injected into the mold cavity, thereby gradually reducing the injection time (which can save material time in many cycles). Just remember to consider the strength required for the product wall and follow best design practices to minimize the wall thickness.

Reduce Wall Thickness

Thinning the wall can not only get your part through the injection stage faster, but also directly affect the cooling time. Less thickness means less cooling time.

In addition, it also includes reasonable control of injection speed and pressure to achieve the best filling effect, avoid overfilling and underfilling problems, and thus reduce cycle time11.

To make cooling more even and avoid hot spots, you can design a good cooling system12. This will help you cool down faster and make more parts. You can also make the cycle shorter by controlling how long you inject and how long you wait before you open the mold.

You can use a sensor to watch how long you inject and how long you wait before you open the mold. Then you can change how long you inject and how long you wait before you open the mold.

When you introduce automated equipment, like robot arms, you can cut down on the time it takes to do things by hand and make your operation more efficient. That means you can make your cycle shorter.

Use advanced monitoring systems and data analysis technology to watch all the different things that happen when you’re doing injection molding in real time. That way, you can catch problems as they happen and make changes to make your cycle better.

Training operators to improve their injection molding skills and knowledge level can help them operate the equipment better and control various parameters more reasonably, so as to achieve a faster cycle.

Cycle time optimization leads to cost savings in injection molding.True

By reducing the overall cycle time, manufacturers can lower energy consumption and increase the number of parts produced in a given period, leading to significant cost savings.

Reducing cycle time always compromises product quality.False

Properly optimizing cycle time can maintain or even enhance product quality through precise control and monitoring of molding parameters.

Conclusion

Cycle time and production efficiency are key factors for measuring the performance of large injection molding machines. With the market getting more competitive and customers demanding more, injection molding companies need to improve cycle time and production efficiency to stay in the game.

In conclusion, by optimizing the injection molding process, using advanced equipment and technology, taking reasonable measures and continuous improvement, the injection molding cycle time and production efficiency of large injection molding machines can be greatly improved.

Injection molding companies should pay close attention to market demand and technological development, continuously improve and innovate, and improve injection molding cycle time and production efficiency to maintain competitiveness and achieve sustainable development.

-

Understanding cycle time is crucial for optimizing production efficiency and product quality in injection molding processes. ↩

-

A gate seal study can significantly improve cycle time and reduce molding inconsistencies, making it essential for production optimization. ↩

-

Exploring cooling time factors can lead to better cycle time management and improved product quality in injection molding. ↩

-

Understanding mold temperature’s effect on cycle time can help optimize production efficiency and part quality. ↩

-

Learning about maintenance practices can prevent failures and enhance the longevity and efficiency of your injection molding machine. ↩

-

Understanding mold design is crucial for optimizing cycle time; this resource will provide insights into effective mold strategies. ↩

-

Understanding cooling channel design can significantly enhance mold efficiency and reduce cycle times, making it a crucial aspect of mold design. ↩

-

Choosing the right plastic material is vital for optimizing production efficiency and ensuring product quality, making this resource essential for manufacturers. ↩

-

Optimizing the injection molding process can lead to significant improvements in cycle time and production efficiency, which is critical for competitive manufacturing. ↩

-

Understanding these parameters is crucial for optimizing production efficiency and achieving high-quality results in injection molding. ↩

-

Discovering strategies to reduce cycle time can significantly boost productivity and lower costs in manufacturing processes. ↩

-

Learn about How many types of cooling systems are there for injection molds?The cooling system of injection molds can be divided into air cooling, water cooling and oil cooling depending on the medium….. ↩