Enhancing the durability of injection-molded plastic products involves optimizing materials, molding techniques, and post-processing methods to improve strength and resistance.

To increase durability, use high-quality resins, optimize molding conditions like temperature and pressure, and consider post-processing treatments such as annealing.

Improving product durability requires a balance of material selection, molding precision, and additional strengthening processes. Learn more about each step for better long-term performance.

Optimizing molding conditions increases plastic product durability.True

Proper temperature and pressure control during injection molding ensure better molecular alignment, leading to stronger and more durable products.

All injection-molded plastic products are equally durable.False

Durability depends on the material used and the specific molding conditions, so not all plastic products share the same level of strength.

How Does Material Selection Affect the Long-Term Durability of Injection Molded Plastic Products?

Material selection is crucial for the longevity and performance of injection-molded plastic products, impacting factors like strength, flexibility, and resistance to wear.

Choosing the right material for injection molding ensures product durability by optimizing factors like temperature resistance, strength, and chemical resistance. Materials like ABS, polycarbonate, and nylon offer varying levels of long-term performance.

Common Plastic Materials and Their Properties

-

Polyethylene (PE): PE has good tolerance to the load and impact but have low strength. Applicable to products that require little or no strength from the fiber.

-

Polypropylene (PP): It has good chemical resistance, low density, and high impact strength making it ideal where the automotive parts are being used and housings of most household appliances.

-

Polystyrene (PS): Good in transparency and easy to process though the toughness and strength of it are low.

-

Polycarbonate (PC): A very good impact strength and transparency and is widely used for high strength/transparent products such as lense used in eyeglasses and safety helmets.

-

Nylon (PA): Large mechanical strength and excellent anti-wear properties for gear, bearing as well as other mechanical components with heavy loads.

-

Polyethylene Terephthalate (PET)1:High mechanical properties and heat resistance as it applicable for high strength and heat application.

-

Acrylonitrile Butadiene Styrene (ABS): Good impact strength, dimensional stability and processability, widely used in auto interior & exterior trim, home appliances and computer casings & frames.

Application of Reinforced Materials

For improving durability of the plastic products the reinforcement like glass fibers, carbon fibers, and mineral fillers can be incorporated into the plastic material. These reinforcing materials can also enhance mechanical properties of the plastics greatly thus making it rigid. For instance glass fiber reinforced polypropylene (GFPP) has better strength and high temperature capability that pure polypropylene.

-

Glass Fiber Reinforcement2:Enhances the mechanical properties such as tensile strength and hardness and thermal stability of plastics used in automobiles, electronic gadgets and industrial applications.

-

Carbon Fiber Reinforcement3:Offers greater strength and modulus, and lighter weight, this material is widely applied on aerospace, automobile construction and high-performance sporting products.

-

Mineral Fillers: Talc powder, quartz sand and other mineral stuffs can improve the rigidity, wear resistance and dimension stability of plastics which can be used in different industrial applications.

Polycarbonate is one of the most durable materials for injection molding.True

Polycarbonate is known for its high impact resistance and durability, making it ideal for products that require long-term performance.

ABS is the best material for all injection-molded products.False

While ABS is versatile, it may not offer the durability required for products exposed to high temperatures or harsh chemicals, making other materials a better choice.

What is the Impact of Product Design Optimization on the Durability of Injection Molded Plastic Products?

Product design optimization plays a crucial role in enhancing the durability of injection-molded plastic products, focusing on material choice, structural integrity, and manufacturing precision.

Optimizing product design improves the durability of injection-molded plastics by selecting appropriate materials, reducing stress concentrations, and ensuring consistent mold performance, leading to longer-lasting products with better performance.

Increasing Wall Thickness

Increasing the wall thickness of plastic products is a direct way of enhancing the strength or stiffness of the item in question. Thicker walls can enhance the flexural strength and impact resistance of products. However, walls that are too thick may prove heavy, costly to make, and may also shrink and warp during injection. Therefore, a balance between strength and weight is needed.

Adding Ribs and Reinforcement

Introducing ribs or reinforcement in the areas of low strength is a very effective way of increasing rigidity or strength. Rib designations and reinforcements should be designed carefully in terms of their placement and dimensions in order not to create areas of high stress concentrations and inadequate filled with the injected material.

Transition Fillet Design

When designing products, it is advisable to shy away from sharp corners or any other structure that may encourages the flow of stress concentrating at that point resulting to crack. Application of transition fillet design can also help to minimize on the stress concentration and hence makes the product durable.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA)4 is a computer based application tool that can be used to predict stress and deformation of products in use or/and in different conditions. FEA can optimize product design, identify weak points, and make improvements to enhance overall strength and durability.

Product design optimization enhances the durability of injection-molded products.True

Design optimization ensures better material selection, structural strength, and consistency in molding, leading to longer product life.

Product design optimization always guarantees higher durability.False

While design optimization significantly improves durability, other factors like material defects or manufacturing issues can still affect the final product's performance.

How to Optimize Mold Design to Improve the Durability of Injection Molded Plastic Products?

Optimizing mold design is key to enhancing the durability of injection molded plastic products, ensuring they perform better and last longer in their intended applications.

Optimizing mold design involves selecting the right material, ensuring proper cooling, and minimizing defects. These adjustments reduce wear, improve product strength, and extend the product’s life cycle.

Runner Design

Runners direct the molten plastic into the mold cavity, and proper runner design ensures uniform filling, reducing flow marks and air bubbles. Some of the ordinary runner designs are primary runner, secondary runner, and the cooling runner.

Cooling System Design

The design of the cooling system has a significant impact on the injection mold tool life5 as well as the overall dimensional stability of the product and its mechanical properties. It is also important to cool the mold so that it cools evenly and warping and shrinkage are minimized, thus producing a durable product.

Venting System Design

Mold venting system help in the removal of air and volatiles from the mold cavity; air bubbles and burn marks on the material can be avoided thus improving the quality and strength of the product being produced.

Optimizing mold design enhances the durability of injection molded plastic products.True

Effective mold design reduces product stress and enhances the structural integrity of the final product, leading to longer-lasting plastic items.

Optimizing mold design guarantees durability in all products.False

While mold design optimization improves durability, it cannot guarantee perfect results for every product due to variables such as material choice and processing conditions.

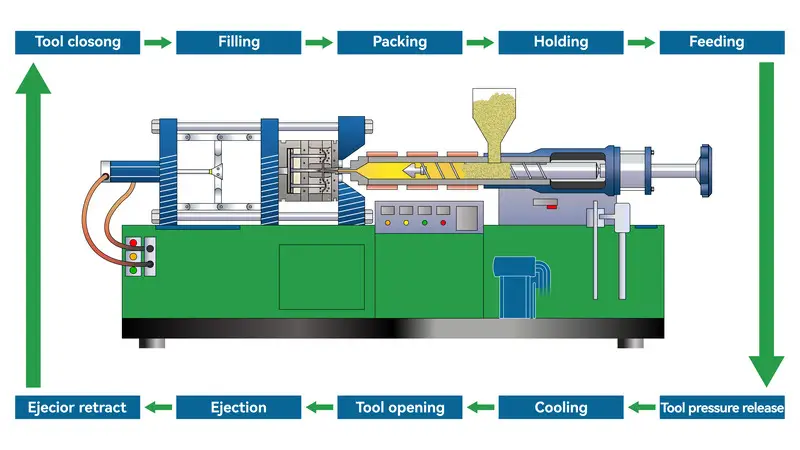

What Role Does the Injection Molding Process Improvement Play in Determining the Durability of Injection Molded Plastic Products?

Process improvements in injection molding are crucial for enhancing the durability of plastic products by optimizing molding conditions and material properties.

Injection molding process improvements, such as better temperature control and optimized cycle times, help improve product durability by reducing defects and enhancing material strength.

Injection Speed and Pressure

The injection speed and pressure should be appropriate to ensure uniform filling as much as possible, avoid voids, bubbles and excessive internal stress. Too high injection speed and pressure will cause wear of the mold and equipment, while too low injection speed and pressure will cause unfilled parts and surface defects.

Holding Pressure and Cooling Time

The holding pressure and cooling time have a huge impact on the dimensional and stress stability of the product. Sufficient holding pressure ensures complete solidification without shrinkage and warping. The cooling time must be adjusted according to the wall thickness and material properties.

Mold Temperature Control

Mold temperature affects filling and final product quality. Proper mold temperature improves plastic flow, ensures complete filling, reduces internal stress, and improves dimensional accuracy and surface quality, extending injection mold lifespan.

Injection molding process improvements increase product durability.True

Optimizing molding conditions such as temperature, pressure, and cycle time can enhance the strength and longevity of molded plastic products.

Process improvements always add significant costs.False

Although some improvements may incur initial costs, they can reduce waste, defects, and increase long-term product durability, ultimately saving on production expenses.

How to Enhance Process Technology to Improve the Durability of Injection Molded Plastic Products?

Enhancing process technology is key to improving the durability of injection molded plastics. By optimizing molding conditions and materials, manufacturers can produce stronger and longer-lasting products.

Improving process technology in injection molding involves optimizing temperature, pressure, and material selection. Key steps include using advanced mold designs, reducing cycle times, and ensuring consistent cooling to enhance durability.

Multiple Injection Molding

Multiple injection molding allows different materials and colors in a single product, increasing the mechanical characteristics and esthetic qualities. For example, dual component has a combination of both softer and rigid material injection moulding mainly for increased impact and comfort.

Gas-Assisted Injection Molding

Nested injection molding also known as gas assistance injection molding, the incorporation of gas during injection to form voids, decreases weight and cost of the material and increases toughness, and sturdiness.

Hot Runner Systems

Hot runner system helps to minimize material usage and number of shots which in turn improves the production rate and quality of the product by increasing the proper flow of molten plastic, eliminating flow marks and decreasing internal stress.

Metal Injection Molding (MIM)

MIM stands for Metal injection molding that molds metals and plastics by fusing metal powders with binding agents, to create complex metal components. MIM can produce stronger metals with high tolerance for Aerospace industry, medical devices and high end production.

Composite Material Injection Molding

Composite material injection molding combines multiple materials to create superior composite products. The incorporation of other materials such as glass or carbon fibers increases its strength, rigidly and also its heat resistant property.

Optimizing molding conditions increases plastic product durability.True

Fine-tuning mold temperature, pressure, and cooling can improve the strength and longevity of the final product.

Faster cycle times always result in more durable products.False

While speed is important, focusing solely on faster cycles can lead to inferior product durability if not balanced with proper cooling and material handling.

How Does Post-Processing Process Affect the Long-Term Durability of Injection Molded Plastic Products?

Post-processing significantly influences the durability of injection-molded plastic products. Key methods like painting, coating, or heat treatment can enhance product lifespan.

Post-processing improves the durability of injection-molded plastics by enhancing resistance to wear, chemicals, and UV damage. Techniques such as coating or heat treatment strengthen the material’s performance.

Annealing

Annealing is a heat treatment that involves heating the material as well as cooling it relatively at a slower rate with a prime intention of getting rid of internal stress. This process decreases the internal stress, eliminating the deformation and cracking, thus increasing durabilities.

Surface Treatment

Spraying, coating, and heat treatments such as hardening increase the antifrictional nature and durability against wear and scratch resistance for increased product life.

-

Spraying: Deposits a layer to append strength for wear and corrosion and to make the product more attractive.

-

Electroplating: Electro deposition of metal layers enhances the wear-friction and corrosion protection along with enhancement in electrical conduction.

-

Laser Engraving: Deposition thin micro patterns and texturing of the desired matter on the surface to increase beauty and identification without changing the mechanical features.

Processing and Assembly

Correct techniques of welding makes strong combinations without loosening and boosts the strength of the system in its entirety. Care should be taken to avoid new stress and damage during processing and assembly.

-

Ultrasonic Welding: Ultrasonic welding is applied to plastic parts to weld them, where it creates a strong bond for products like electronics and car parts.

-

Hot Plate Welding: Hot plate welding employs the use of heated plate to melt plastics in order to bond the parts hence useful for large and complex shape.

Post-processing improves the durability of injection-molded plastics.True

Methods like coating, painting, or heat treatment can increase resistance to wear, chemicals, and UV exposure, enhancing product longevity.

Post-processing is always necessary for injection-molded plastic products.False

While post-processing can improve durability, not all injection-molded plastics require it, as some are durable enough without additional treatments.

How Do we Quality Control or Test the Durability of Injection Molded Plastic Products?

Quality control and durability testing ensure the injection molded plastic products meet required standards and perform optimally across various applications.

Durability testing for injection molded plastic involves stress tests, thermal cycling, and impact resistance tests. Quality control methods like visual inspections, dimensional checks, and material testing ensure that products meet specifications and function properly.

Common Quality Testing Methods

-

Tensile Testing: Used to obtain tensile strength and elongation; these are important parameters for assessing the mechanical characteristics.

-

Impact Testing:Tools used to determine the impact resistance includes Charpy and Izod tests.

-

Hardness Testing: Used for evaluating the wear and scratch resistances, is the one that measures the surface hardness.

Quality Management Systems

Adoption of Quality management systems6 such as ISO 9001 also check on the convectional manufacturing system enabling provision of consistent products.

Non-Destructive Testing

Non-destructive testing7 methods like X-ray, ultrasound, and infrared imaging detect internal defects and structural integrity without damaging the product, ensuring quality and safety.

Durability testing involves thermal cycling and impact resistance tests.True

Thermal cycling tests the product's response to temperature extremes, while impact resistance tests evaluate its ability to withstand sudden forces.

Quality control always requires expensive equipment.False

While specialized equipment can enhance testing, many quality control measures such as visual inspections and simple measurements can be done affordably.

What Case Studies Have Demonstrated Successful Strategies for Improving the Durability of Injection Molded Plastic Products?

Several case studies highlight effective strategies for improving the durability of injection molded plastic products, focusing on material selection, process optimization, and post-molding treatments.

Successful strategies for improving durability in injection molding include using reinforced materials, optimizing molding parameters, and applying surface treatments. These approaches enhance the lifespan and performance of plastic parts across industries such as automotive, medical, and consumer goods.

Material Selection

Use polypropylene (PP) for its hardness and impact strength. Strengthen with glass fibers (GFPP) in order to get more stiffness and less elasticity.

Design Optimization

Add ribs and reinforcement underneath the bumper’s skin working on the increased body stiffness. Use transition fillet design to reduce stress concentration.

Process Improvement

Adjust injection speed8 & pressure for total fill & forming. Regulate holding pressure and the cooling rate for consistency in sizes and low levels of internal stress. Control mold temperature to improve the movement of the manner and lessen the built-in stress.

Post-Treatment Processes

Apply annealing to reduce internal stress and strengthen material’s endurance. Use surface spraying to enhance the wear property and the scratch property. Employ the right bonding and acceptable methods of welding for strong joints.

Conclusion

The process of increasing the durability of injection-molded plastic products is quite a complicated process which includes the choice of material, design of the product, modification of the process, and post-treatment of the product.

By optimizing these aspects, the strength and durability of plastic products can be significantly improved, meeting various application requirements. With the development of new materials and the improvement of injection molding technology, the durability of injection molded products will continue to improve, providing high-quality and high-reliability plastic products for different industries.

-

Explore the unique properties and applications of PET, a versatile plastic used in various industries, to understand its significance better. ↩

-

Learn about the advantages of glass fiber reinforcement in enhancing the mechanical properties of plastics for various applications. ↩

-

Discover how carbon fiber reinforcement enhances the strength and performance of plastics, making them suitable for high-demand applications. ↩

-

Explore this resource to understand how FEA can optimize product design and enhance durability through stress prediction. ↩

-

Learning about mold tool life can lead to better maintenance practices and longer-lasting tools, saving costs in production. ↩

-

Exploring this resource will provide insights into how quality management systems enhance product consistency and reliability. ↩

-

This link will help you understand various non-destructive testing methods and their importance in ensuring product quality and safety. ↩

-

Learn aboutWhy is injection speed important?Injection speed is a critical factor when creating a plastic product. ↩