Regular maintenance of an injection molding machine ensures optimal performance, reduces downtime, and prolongs equipment lifespan. Follow key maintenance practices to prevent costly repairs and improve efficiency.

To maintain an injection molding machine, regularly clean components, check hydraulic systems, lubricate moving parts, and inspect molds. Routine maintenance prevents malfunctions, extends the machine’s lifespan, and improves production efficiency.

While these practices provide a foundation for maintaining injection molding machines, understanding the specific needs of your equipment will further enhance operational performance. Learn more about advanced maintenance techniques to maximize your machine’s efficiency.

Regular maintenance extends the lifespan of an injection molding machine.True

By performing routine checks and repairs, wear and tear are minimized, leading to a longer operational life.

Maintenance of injection molding machines requires costly repairs.False

Regular maintenance typically reduces the need for major repairs, saving costs in the long run by avoiding extensive damage.

What are the Daily Maintenance of Injection Molding Machines?

Daily maintenance of injection molding machines is vital for ensuring optimal performance, reducing downtime, and extending machine lifespan. This involves cleaning, lubrication, and checking critical components.

Daily maintenance tasks for injection molding machines include cleaning the mold, checking hydraulic and cooling systems, lubricating moving parts, and ensuring proper calibration. These actions prevent wear and tear, ensuring smooth operations and consistent part quality.

Cleaning Work

Cleaning is one of the most basic tasks in daily maintenance of injection molding machines, including the following aspects:

-

External Cleaning: The machine must always be kept clean both inside and outside, wipe the machine with a cloth every day, clean the surroundings of the injection molding machine frequently, and be careful to prevent dust and dirt particles from entering the machine.

-

Mold Cleaning: Some molds can get contaminated with oil stains and/or remnants of the plastic they were molded from, and therefore have to be cleaned periodically. Ensure that little or no stains get on the molds through the use of appropriate cleaning agents and equipment.

-

Barrel Cleaning: It is also good practice to flush out any remaining plastic from the barrel after each material change or after a shutdown in case materials mix, this will cause problem in the production of the final product.

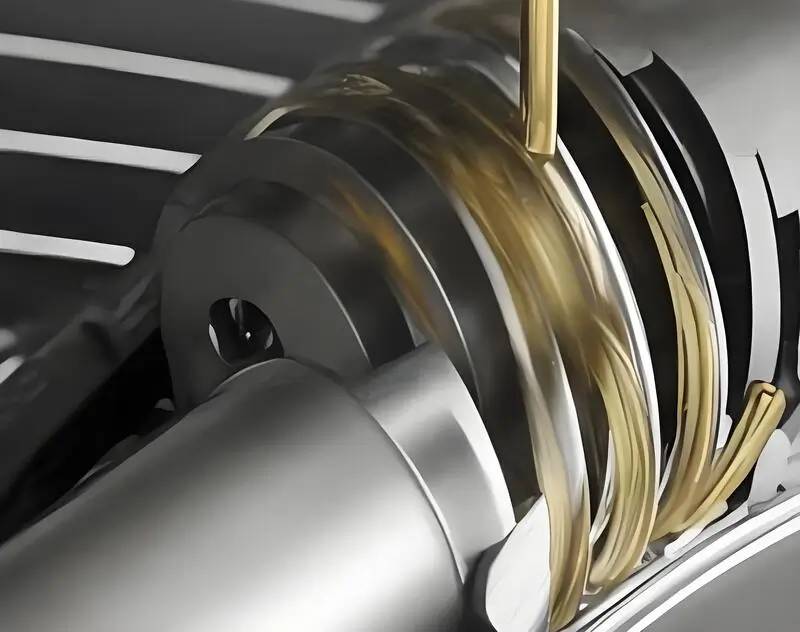

Lubrication Work

Lubrication is vital for smooth operation and extending the lifespan of the injection molding machine. This includes:

-

Lubrication Oil Check: It is recommended to check the oil level and the quality of lubrication oil, its replenishment or replacement on a regular basis. Conduction of working parts and moving parts need particular attention that they are adequately lubricated.

-

Grease Addition: Grease the part as often as is required particularly the parts with slides and linkages typically get greased. See that the grease is free from any contamination otherwise the rubbing will take place on the contaminated grease.

Electrical System Maintenance

Electrical system is one of the most important subsystems of an injection molding machine. Daily maintenance should focus on:

-

Checking Cables and Connectors: Cables and connectors should be checked often for loosening , wear or aging and the bad ones should be replaced at once.

-

Cleaning Electrical Cabinets: To avoid dust and debris getting into the electrical cabinets keep them clean. Regularly inspect the components within the cabinet to ensure reliable operation.

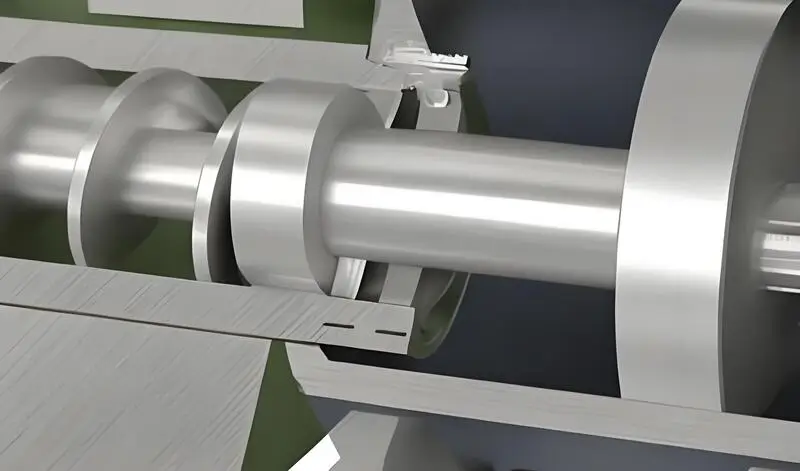

Hydraulic System Maintenance

Hydraulic system1 is one of the core sub systems of the injection molding machine. Daily maintenance should include:

-

Checking Hydraulic Oil: Making sure that the hydraulic oil level and its condition is good, add oil or change the oil if needed on regular basis. Hydraulic oil should be clean instead of contaminated as this might harm the hydraulic system.

-

Cleaning the Hydraulic System: This is on proper maintenance of the hydraulic system by often cleaning the filters and the tanks so that oil circulation can freely happen.

-

Inspecting Hydraulic Lines: The hydraulic lines should be checked for signs of leakage, signs of corrosion, or mechanical damages and any line that is found to be damaged should be replaced as soon as possible.

Maintaining an injection molding machine involves several critical steps to ensure its optimal performance and longevity. One of the key factors is monitoring the pressure oil viscosity, as deteriorated pressure oil can lead to various issues such as oil valve failure and oil seal failure. Regularly inspecting and replacing the pressure relief valve is essential to prevent potential malfunctions.

Additionally, the use of clean pressure oil is crucial in maintaining the efficiency of the machine. It is also important to regularly check for compressed air leaks, as these can impact the overall functioning of the system. Creating and adhering to a comprehensive checklist injection molding machines can help in systematically addressing these maintenance tasks and ensuring the machine operates smoothly.

Daily maintenance helps prevent machine breakdowns.True

Regular maintenance minimizes the risk of malfunction by addressing potential issues early and ensuring all parts function properly.

Daily maintenance is unnecessary for new injection molding machines.False

Even new machines require daily checks and upkeep to ensure optimal performance and to avoid long-term damage from overlooked issues.

What are the Regular Inspections of Injection Molding Machines?

Regular inspections of injection molding machines ensure optimal performance, safety, and product quality. These checks help prevent costly downtime and improve efficiency in production.

Regular inspections of injection molding machines include checking hydraulic systems, molds, temperature controls, and mechanical parts. They ensure proper function and prevent malfunctions, leading to improved part quality and reduced maintenance costs.

Monthly Inspections

-

Check Fasteners: Check all bolts and nuts of the injection molding machine for looseness, particularly on moving and high presser areas and tighten all loose screws.

-

Inspect Lubrication System: Check that all them lubrication points are being supplied with oil. Make sure the oil quality and its level is good, if not then change it.

-

Inspect Electrical System: Check the operation of the electrical system, particularly the motor, heaters, and controllers. Ensure the electrical components and terminal connections are secure.

Quarterly Inspections

-

Hydraulic System Inspection: A thorough check on the hydraulic oil and their condition, as well as washing of the filters and the tanks. Inspect all plumbing lines for any leakage and in cases of damage; He should replace the damaged part.

-

Electrical System Inspection: Examine all the electrical parts especially motors, heaters and controllers. Check the electrical cabinets and service them thoroughly to be able to operate properly.

-

Mechanical System Inspection: Clean and check gears and other parts like screws and barrels, slides and linkages for wear and tear and replace them when necessary. Check the alignment and calibration of the machine.

Annual Inspections

-

Comprehensive Hydraulic System Inspection: A scheduled inspection and servicing of the hydraulic system is recommended, this maybe a general overhaul of hydraulic oil and filters if needed. Check the hydraulic pump, valves and the cylinders and any damaged part should be repaired or replaced.

-

Comprehensive Electrical System Inspection: Make sure that you have checked and inspected the electrical control system of the equipment correctly. Wash the interior of the electrical cabinets and check the loose connections of electrical parts and terminal for safe and efficient connections.

-

Comprehensive Mechanical System Inspection: Completely overhaul the mechanical part and if the parts have worn out then change them. The alignment and calibration of the machine should be checked to determine normal working status.

Regular inspections improve injection molding machine efficiency.True

Routine checks ensure all components function properly, reducing downtime and enhancing the overall efficiency of the machine.

Regular inspections are only necessary for old machines.False

New machines also require inspections to maintain optimal performance and prevent early wear and tear.

What are the Troubleshooting Methods for Injection Molding Machines?

Troubleshooting injection molding machines ensures smooth operations by identifying and fixing common issues like improper molding, material defects, or machine malfunctions. Proper diagnostics improve efficiency and reduce downtime.

Troubleshooting methods for injection molding machines involve checking key areas such as temperature, pressure, mold design, and material flow. Adjusting machine settings or replacing worn parts can resolve many common issues, enhancing production efficiency.

Hydraulic System Failures

-

High Hydraulic Oil Temperature: This may be attributed to; faulty cooling system or hydraulic oil viscosity is too high. Effectiveness of the cooling system should be tested, cooler and filters should be cleaned and hydraulic oil should be replenished if required.

-

Hydraulic Oil Leakage: This could be as a result of Hydraulic line or connector problems. Any frayed or damaged line and connectors should be checked and replaced as soon as possible.

-

Excessive Noise in Hydraulic System: This could be due to death of hydraulic pump or valves needed to help in the running of the hydraulic system. Check the pump and value and if they are damaged they should be mended or replaced as the case maybe.

Electrical System Failures

-

Motor Not Starting: It could be attributed to a problem with the power supply or the motor of the device among other problems. Look at the connections of the power and the motor also consider replacing the damaged electrical parts immediately.

-

Heater Not Heating: This could be due to a malfunctioning heater or control system. Conduct a detailed check on heater and control system and if there is any damage fix it.

-

Controller Malfunction: This could be as a result of defective electrical resistant or the terminal connections to the electrical components may be loose. Inspect the controller and terminal connections, and replace any damaged electrical components.

Mechanical System Failures

-

Screw Wear: This might be due to material wear or lack of sufficient lubrication on the tool and the work piece. Thumb through the screw from time to time and should there be signs of wear, then it should be replaced. Check whether the lubrication system is in order.

-

Barrel Wear: This may be as a result of the material getting worn out or due to washing in wrong manner. Inspect the barrel perastically and change the barrel if commonly worn out. Make sure the barrel is also clean in order to avoid influences of remaining plastic materials on the products’ quality.

-

Slide Wear: This could be as a result of wrong lubrication or foul friction of the part against other parts. Some of the preventive maintenance are: Check the condition of the slides from time to time and change the worn out ones if any. Check that the functions of the lubrication system are okay.

Proper troubleshooting increases machine lifespan.True

Addressing issues like overheating or improper settings helps prevent excessive wear and tear on the machine, extending its operational life.

Troubleshooting always requires expert intervention.False

Many common issues can be resolved by adjusting machine settings or cleaning components, but more complex problems may require expert intervention.

What Should be Paid Attention to When Maintaining Injection Molding Machines?

Proper maintenance of injection molding machines is essential for ensuring longevity, minimizing downtime, and maximizing production efficiency. Regular care improves performance and reduces unexpected breakdowns.

Key maintenance practices include regular cleaning, lubrication, checking for wear on components, and ensuring proper alignment. Proper calibration and preventive maintenance help in extending machine life and preventing costly repairs.

Safety First

In performing maintenance always ensure this is done safely. Switch off the power and hydraulic systems so that there is no mishap that may occur. This is the reason why protective gear like gloves and safety glasses should be worn to avoid any harm to the person.

Use Appropriate Tools and Materials

Use appropriate tools and materials for maintenance. Inappropriate tools and inferior materials should not be used on the equipment, pay attention to the selection of lubricants and greases2, and use lubricants and greases recommended by the manufacturer.

Record Maintenance Activities

Maintenance journals should also be well written and contain the date on which they were conducted, what was done and any issues noted. Form a basis of records for systematic maintenance of the equipment in order to attain a steady long-run stable condition.

Train and Improve the Skills of Operators

Proper maintenance requires specialized knowledge and skills. Strengthen the provision of training to the operators with a view of upgrading their maintenance abilities. As part of the maintenance, it is recommended to hold training sessions to update the staff on the use of modern technologies to create conditions for the efficient functioning of the equipment.

Routine maintenance is critical for injection molding machine longevity.True

Regular cleaning, lubrication, and calibration reduce wear and tear, extending the machine's lifespan and maintaining production efficiency.

Ignoring maintenance does not affect the performance of injection molding machines.False

Neglecting maintenance can lead to machine malfunctions, increased downtime, and costly repairs, ultimately reducing productivity.

What are the Maintenance And Repair Steps?

Regular maintenance and timely repairs are essential to keep your machinery running smoothly and prevent unexpected downtime. Proper care ensures longevity and optimal performance.

Regular cleaning, checking for wear and tear, and replacing damaged components are key to maintaining and repairing equipment. Inspecting the system regularly can prevent costly repairs and improve overall efficiency.

Lubrication System Maintenance Steps

-

Check Lubrication Oil Levels: The lubrication oil should also be checked on daily basis before operating the machine and it should be within the normal limit.

-

Lubricate Components: Lubricate slides, guides, connecting rods, rotating shafts, etc. regularly according to the manufacturer\’s recommendations.

-

Replace Lubrication Oil: Change the lubrication oil every half yearly or once in a year depending on the usage and the life of the oil to avoid contamination and effectivity.

Hydraulic System Maintenance Steps

-

Check Hydraulic Oil Levels: Hydraulic oil should be checked regularly- before operating the machine – to determine if they are within the normal level.

-

Clean Hydraulic Filters: Replace hydraulic filters every 90 days to avoid cases of some contaminants penetrating the system, and making sure that the hydraulic oil is clean.

-

Replace Hydraulic Oil: Depending on usage and operating conditions, replace the hydraulic oil at least once or twice every two years.

-

Inspect Hydraulic Lines: Hydraulic lines and connectors should be checked for leaks, signs of aging, or damage and any such should be replaced as soon as possible.

Electrical System Maintenance Steps

-

Check Power Connections: Check the power connections daily before starting the machine to ensure they are secure and undamaged.

-

Clean Electrical Cabinets: Wipe the electrical cabinets once a month to avoid dust and other materials from getting in and thus the electrical system runs as expected.

-

Inspect Electrical Components: Inspect electrical components such as motors, heaters, and controllers quarterly to ensure they are functioning properly.

-

Replace Damaged Electrical Components: Fix or replace any defective component that is in the electrical system as this will guarantee the right performance of the electrical system.

Mechanical System Maintenance Steps

-

Inspect Screws and Barrels: Daily check on the screws and barrels3where it should be worn out or damaged to ensure they are in good condition.

-

Clean Molds: Clean plastic injection mold 4 and mold cavities after each change or shutdown to prevent oil stains and residual plastic from affecting normal use.

-

Replace Worn Parts: Regularly check mechanical parts for signs of wear and replace all worn parts such as screws, barrels, slides and connecting rods.

-

Calibrate Mechanical Parts: Regularly adjust mechanical parts to ensure that the injection molding machine is accurate and stable.

Routine maintenance extends equipment lifespan.True

Regular maintenance helps detect issues early and ensures that machinery operates at peak efficiency, extending its useful life.

Repairs are always more expensive than preventative maintenance.False

While repairs can be costly, neglecting maintenance often leads to more expensive and extensive repairs down the line.

What is the Future Trend of Injection Molding Machine Maintenance?

The future of injection molding machine maintenance focuses on automation, predictive analytics, and improved energy efficiency to enhance machine longevity and reduce downtime.

Future trends in injection molding machine maintenance include the use of AI-driven predictive maintenance, real-time monitoring, and energy-saving technologies to reduce operational costs and increase machine uptime.

Intelligent Maintenance

With the help of Internet of things and big data, the maintenance of injection molding machines will become much smarter. Real time data acquirement and the use of sensors can track the machine operation and detect issues before they occur, or before they turn into major issues, that will require repair or replacement.

Remote Monitoring

Internet and cloud platform can be used to monitor and maintain injection molding machines at a distance. Users and manufacturers can therefore keep track of the machine and reduce on time that an error takes hence minimizing on the cost that comes with maintenance.

Personalized Services

Offer maintenance services according to the various client’s requirements. With the help of big data analysis and AI technologies, it becomes possible to develop an individual schedule for the functioning of each machine to increase its productivity and lifetime.

Environmental Protection and Energy Saving

Due to the continuing emphasis on environmental and energy saving measures, maintenance of injection molding machines will give more consideration to the protection of the environment and energy efficiency. The goals will be derived from the optimal selection of eco-friendly lubrication fluids and hydraulic oils, improved setting of operating parameters, minimization of energy utilization and forthcoming pollutions.

Predictive maintenance enhances injection molding machine longevity.True

Predictive maintenance uses real-time data to forecast potential issues, allowing for timely repairs and preventing major breakdowns, thus extending machine life.

All injection molding machines will rely on AI-driven maintenance in the future.False

While AI-driven maintenance is a growing trend, not all injection molding machines will transition to AI systems in the immediate future, especially in small-scale or traditional settings.

Conclusion

The important part of injection molding machines5 is their maintenance because only with it the machines will work stably and produce high-quality products for a long time. The way of daily maintenance, periodical inspection and fault handling can also prolong the service life of injection molding machines and enhance the productivity.

The most important parts of the maintenance process include concerns of safety, choice of tools and materials, record keeping, and noting the qualifications of the operators. Only when it is comprehensively maintained can injection molding machines run stably, thus providing more considerable economic benefits to enterprises.

Looking forward to the future of injection molding machine maintenance, with the further development of new technologies, injection molding machine lubrication 6will be more intelligent, non-contact, targeted, and green, and will have a stronger support force for the development of the manufacturing industry.

-

Learn about What Is a Hydraulic System? Definition, Design, and Components : The purpose of a specific hydraulic system may vary, but all hydraulic systems work through the same basic concept. ↩

-

Learn about Grease (lubricant) : Grease is a solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. ↩

-

Learn about 3 Minutes to Understand Screw and Barrel for Injection Molding, Extruders and Food Processing : Screws and barrels are essential components in plastic processing machines, including injection molding machines and extruders, as well as in the food processing industry. ↩

-

Learn about Everything You Need to Know about Plastic Injection Molds: Plastic injection molds shape plastic by injecting molten material into a mold cavity, where it cools and solidifies into a part. ↩

-

Learn about Injection molding machine: An injection molding machine is a machine for manufacturing plastic products by the injection molding process. ↩

-

Learn about Injection Molding Machine Lubrication Systems : An automatic lubrication system keeps your machinery running at peak levels leading to minimized downtime and reduced maintenance costs. ↩