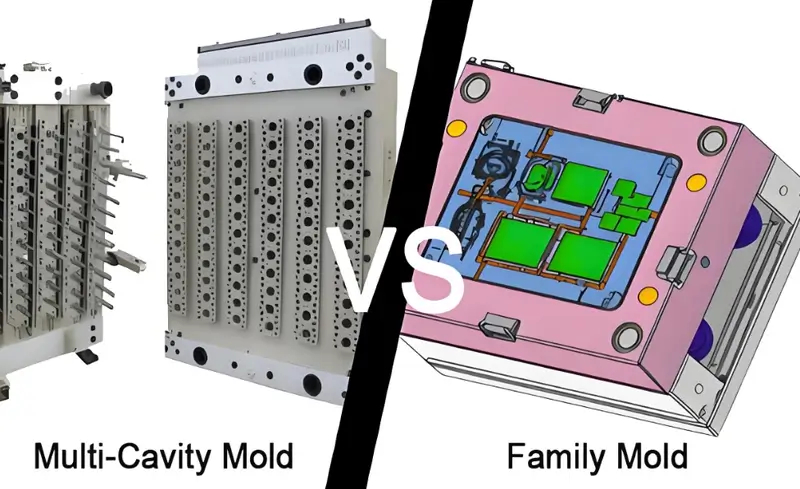

Multi cavity molds and family molds are both used in injection molding, but they differ in design and application. Understanding the difference is key to choosing the right tool for your manufacturing needs.

Multi cavity molds produce identical parts in each cavity, while family molds create different parts in one mold. Multi cavity molds improve efficiency, while family molds are ideal for producing various products simultaneously, reducing tool change time.

To choose the best mold for your project, consider factors like part type, production volume, and cost efficiency. Learn more about each mold’s strengths to optimize your production process.

Multi cavity molds are more cost-effective for high-volume production.True

Multi cavity molds allow for the simultaneous production of identical parts, increasing efficiency and reducing costs in large-scale manufacturing.

Family molds are always the better choice for varied product designs.False

While family molds are useful for producing multiple parts in one cycle, they may not offer the same efficiency or quality as multi cavity molds for high-volume identical parts.

What is the Definition of Multi-Cavity Injection Molds and Family Injection Molds?

Multi-cavity and family injection molds are essential tools in manufacturing, enabling efficient production of multiple parts in a single cycle. They significantly improve output and reduce costs.

Multi-cavity molds allow the production of several identical parts per cycle, while family molds produce different parts in one cycle. Both are used to increase production efficiency and reduce costs in high-volume manufacturing.

Multi-Cavity Injection Mold

Multi-cavity injection molds refer to molds that contain multiple identical cavities. All cavities either produce the same product or different products.

The purpose of multi-cavity mold design is to produce multiple products in the same injection cycle1 to improve productivity. Multi cavity injection molding is suitable for situations where a large number of similar small parts need to be manufactured, such as bottle caps, toothbrush handles, and some medical devices.

Family Injection Mold

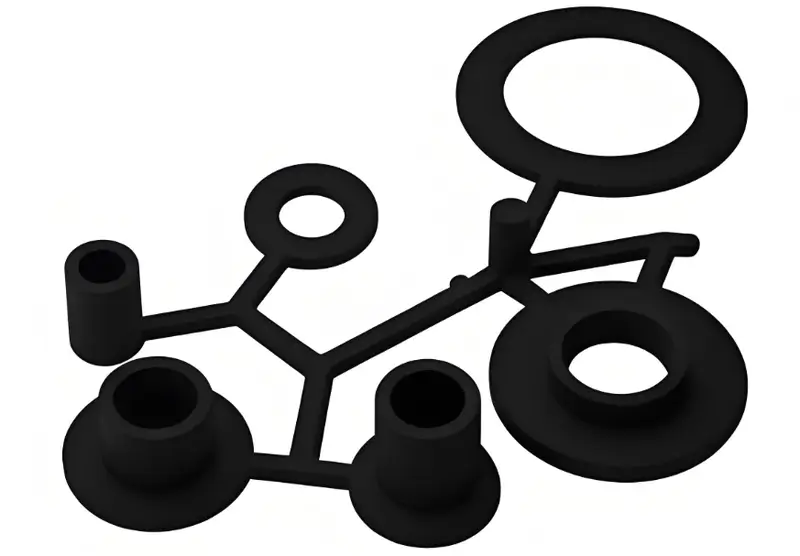

A family injection mold or a combination mold is a single mold which has more than one cavity and each cavity forms a different multiple parts or product.

A family injection mold has more than one cavity cut into the mold, allowing multiple various parts with the same material to be formed in a single cycle. The direction of this mold design is to create a group of parts that are usually combined into a single product, in a single cycle of the injection molding process2. Family injection molds are prevalently applied in the manufacturing of toys, electrical goods’ cases, household utensils, and other similar products to be assembled.

Multi-cavity molds increase production efficiency.True

By molding multiple identical parts simultaneously, multi-cavity molds optimize production and reduce cycle time.

Family molds always produce parts of the same design.False

Family molds allow different parts to be produced together, but they can vary in shape and design while still fitting within the same mold.

What are the Design Features of Multi-Cavity Injection Molds And Family Injection Molds?

Multi-cavity and family injection molds are designed to produce multiple parts in one cycle, enhancing production efficiency and reducing costs. Understanding their features can optimize your molding process.

Multi-cavity molds increase productivity by molding several identical parts simultaneously. Family molds allow different parts to be molded together in one cycle, saving time and reducing tooling costs. Both designs improve manufacturing efficiency and reduce cycle times.

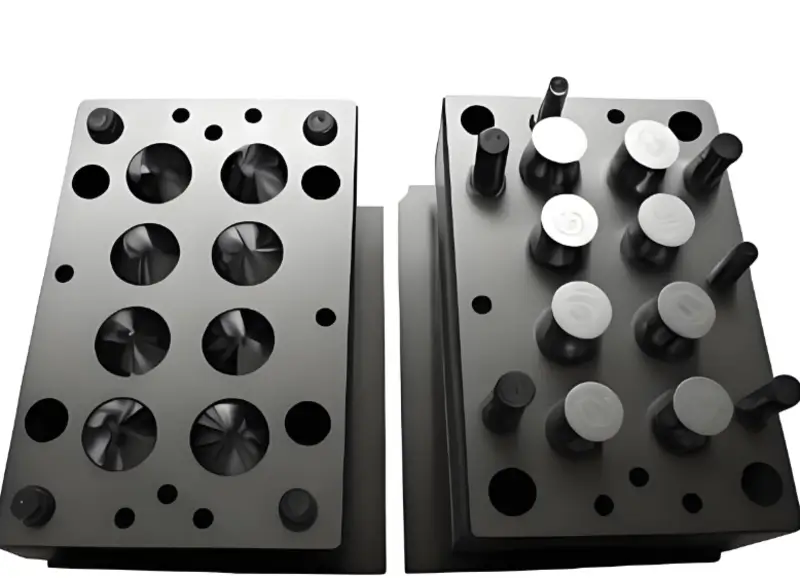

Multi-Cavity Injection Mold

-

Number of Cavities: Multi-cavity molds can include 2 to dozens of cavities; in total depending on the size of the product and capability of injection molding machine. Some of the common multi-cavity molds are 4 cavity mold, 8 cavity mold, 16 cavity mold, 32 cavity mold and such more.

-

Cavity Layout:The design of the cavities should also undertake the issue of melt flow balance, cooling system3, structural stability of the mold. A cavity layout could be linear, matrix or circular the type depending on the layout of the mold and the desired shape of the final product.

-

Runner Design: To ensure simultaneous filling of each cavity, the runner system4, including the main runner, sub-runner, and gate, must be carefully designed. Therefore, the runner design5 has to facilitate equal flow of the melt and reduce pressure drop and shear effect of the runner.

Family Injection Mold

-

Variety of Cavities: Every cavity of a family mold makes a different part. These parts are typically the various components that make up a particular product, for instance, functional elements in a toy or segments of a gadget’s body.

-

Product Compatibility: The parts produced by the family mold are usually used to assemble the same product, so their compatibility in terms of physical and functional characteristics must be provided. When designing, the assembly tolerances as well as the functional matching must be considered.

-

Runner Design:Family mold is somewhat similar to the multi-cavity mold but here the in flow system of the mold has to be designed according to the flow requirement of the cavity. The filling speed as well as the pressure could vary within the different parts of the molding, so the runner design of each cavity may need to be changed.

Multi-cavity molds reduce production costs by molding multiple parts at once.True

By producing several identical parts in one cycle, multi-cavity molds reduce cycle time and overall production costs.

Family molds are suitable for molding parts of different shapes.False

Family molds are designed to mold similar parts, not a variety of shapes, to maintain consistency and quality during production.

What are the Application Scenarios of Multi-Cavity Injection Molds And Family Injection Molds?

Multi-cavity and family injection molds enhance production efficiency by producing multiple parts simultaneously or in a single mold. These molds are crucial in high-volume manufacturing.

Multi-cavity injection molds produce several identical parts at once, while family injection molds make different parts in one cycle. Both are widely used in automotive, consumer products, and medical device industries to increase production efficiency and reduce costs.

Multi-Cavity Injection Mold

-

Mass Production: Useful for developing many pieces that are of the same design and shape as products like bottle cap and toothbrush handles. The production pace of these products is relatively high and the demand is also usually high and, therefore, it has to be efficiently produced.

-

Lower Unit Cost: When several products are made at once this cuts the unit cost immensely. Due to the high efficiency of multi-cavity molds’ production technique, the marginal cost per unit of the end product decreases.

-

High Production Efficiency: Multi cavity mold applicable to production tasks that call for high productivity rates with small cycle time. For instance, in medical devices industry, there are quite a number of disposable medical needs to be produced in large quantities and in a short time frame, which multi cavity molds can fulfill.

Family Injection Mold

-

Assembly Product Production: Ideal for making several diverse parts that make up a final product, for instance toys, and casings for electronics. Family molds can produce all necessary parts in one injection molding cycle, simplifying the production process.

-

Small Batch Diversified Production: It is more appropriate for creating many different products in lesser amounts. Due to this flexibility, family molds are useful in small-batch production, especially in markets with rapidly changing demands.

-

Lower Mold Cost: Reusing the same mold to manufacture a form or several parts decreases the mold establishing cost and production cost as well. In the case of small-batch, multi-variety production, family molds are a cost-effective choice.

Multi-cavity molds improve efficiency by producing multiple identical parts.True

Multi-cavity molds allow simultaneous production of identical parts, reducing cycle time and increasing throughput.

Family injection molds are always used for different parts in a single mold.False

Family injection molds can produce different parts, but the design must ensure the parts can be molded simultaneously without compromising quality.

What are the Advantages And Disadvantages of Multi-Cavity Injection Molds And Family Injection Molds?

Multi-cavity and family injection molds are widely used to increase production efficiency. Each has its unique benefits and challenges, depending on the product design and manufacturing needs .

Multi-cavity molds increase productivity by producing multiple parts in one cycle, while family molds allow different parts to be produced together. The main advantage is higher efficiency; however, mold complexity and cost can be higher.

Multi-Cavity Injection Mold

Advantages:

-

High Production Efficiency: Compared with single-cavity molds, multi-cavity molds can produce multiple products in one production cycle, saving time. Multi-cavity molds are particularly prominent in high-demand production scenarios.

-

Low Unit Cost: Multi-cavity molds are suitable for mass production and can reduce the manufacturing cost of a unit product. By using multi-cavity molds, the unit product cost is low, thereby enhancing the competitiveness among manufacturing companies.

-

High Consistency: In the case of molds for all cavities, they are produced at the same time and this has a good bearing on the general quality of the products. Multi-cavity molds use the same mold to make multiple products at a time which are all identical, hence achieving consistent and stable quality.

Disadvantages:

-

High Mold Cost:The manufacture of molds and its designing is quite challenging and expensive. Compared with single-cavity mold, multi-cavity molds involve high precision processing equipment and techniques, therefore substantially capital intensive at the beginning.

-

High Debugging Difficulty: Multi-cavity molds are more delicate to debug and maintain, thus they demand technical support that is of a higher level. The filling and cooling of each cavity have to be strictly attended, so debugging take much time.

-

Difficult Melt Flow Control: To achieve co-molding and equal content in each cavity; the design of the runner system has to be well done. The rich structure of the runner complicates the process of manufacturing and debugging of the mold significantly.

Family Injection Mold

Advantages:

-

Versatility: Can create multiple different parts in one molding hence making it to be very flexible. Relative to other methods, family molds have many advantages when making products involving many components.

-

Lower Mold Development Cost: When several different parts are produced using one mold, the number of molds that needs to be developed as well as the manufacturing cost is minimized. Especially in small-batch, multi-variety production, where large number of items, small-size, multi-variety are characteristic, family molds have a definite tooling costs superiority.

-

Suitable for Small-Batch Production: Able to manufacture a range of products while at the same time being suited for limited productions. Largely, family molds are suitable for small part production due to availability of adjustable forms and flexibility of molds.

Disadvantages:

-

Lower Production Efficiency: While using a family mold, cycle output is considerably lower as opposed to when a multi-cavity mold is used. Indeed, due to the fact that each cavity creates distinct components, the productivity rate is lower compared to the multi-cavity molds.

-

Lower Product Consistency: Different cavities may produce the parts although there may be some problems related to casting consistency. Family molds may have issues with part quality and consistency when producing different parts.

-

Complex Runner Design: Requires a well-developed runner system that will be effective in fulfilling the said needs of the several sections and demanding the quality of each part. The structure of the runner is more complex, it has raised the difficulty of the mold manufacturing and mold debugging.

Multi-cavity molds increase production efficiency.True

Multi-cavity molds allow the production of several parts in a single cycle, leading to higher output and reduced per-part costs.

Family molds are always more cost-effective than multi-cavity molds.False

While family molds can be more cost-effective in certain cases, their design complexity and limitations in part compatibility can lead to higher costs in specific applications.

What are the Specific Applications of Multi-Cavity Injection Molds And Family Injection Molds in the Injection Molding Process?

Multi-cavity and family injection molds are used to produce multiple parts simultaneously, improving productivity and reducing costs in high-volume manufacturing.

Multi-cavity molds produce several identical parts in a single cycle, while family molds produce different parts in one shot, saving time and material. These molds are ideal for automotive, consumer products, and medical device industries.

Applications of Multi-Cavity Injection Molds

Injection molds with multiple cavities are common in contexts where it is necessary to produce numerous similar items at once.

For instance, in bottles caps, toothbrush handle, electronic products casings and the likes, Multi-cavity moulds can produce many products in one cycle hence increasing efficiency and productivity. Further, in industries including medical equipment and car accessories, it is also impossible to do without multi-cavity molds.

In practical applications, the construction and usage of multi-cavity molds entail the analysis of various aspects. First, the number of cavities as pursuant to its demand of the product and the capacity of the injection molding machine have to be determined.

Second, the runner system design is also important and must guarantee the melt flow distribution for each cavity equally. Also, the design of the cooling system6 is crucial as it should meet the quality of the product and the efficiency of production processes.

- Case Study:A manufacturing firm specialising in medical devices is required to supply large quantities of a disposable syringe to the market. The manufacturing with multi-cavity injection molds was chosen by the company. After the extensive identification of requirements and selection of a suitable design, the company then opted for a 48-cavity mold. By the well planned runner and cooling system the equal distribution for filling and cooling of every cavity is possible. In production, four dozen syringes can be manufactured at once during an injection molding cycle, these can greatly enhance the production rate and caters for market requirement of high quality medical related products.

Applications of Family Injection Molds

Family injection molds are typically used more extensively in the creation of a variety of unique components and the subsequent assembly objects.

For instance in toy manufacturing, a family tool can make several aspects of the toy all at once and hence saves on the costs of developing more molds while at the same time allowing manufacturers to work on more toys at the same time. Family molds are also commonly used in producing electronic product casings, household items, and other fields requiring a set of related parts.

In practical applications, the design and use of series molds are also accompanied by other factors that need to be considered. First, the design in the mold needs to meet the production requirements of different parts.

Secondly, for the runner system design, attention needs to be paid to the filling and cooling requirements of different cavities. Finally, technical support is needed for the function and correction of the mold in order to have a complete production line and high-quality products.

- Case Study:A toy factory needs to produce a new toy consisting of several different components. In order to reduce mold development costs, they decided to use a serial injection mold. This mold design consists of six cavities, each of which is used to make a different part of the toy. With the help of the runner system, uniform material flow and cooling to all cavities can be achieved. In production, one plastic injection molding cycle can make six different parts at the same time and then assemble them, making production more flexible and fast.

Multi-cavity molds improve efficiency by producing multiple parts per cycle.True

By utilizing multiple cavities, the production of identical parts is streamlined, reducing cycle times and costs.

Family molds always offer better cost savings than multi-cavity molds.False

While family molds can save material costs when producing different parts, multi-cavity molds tend to be more efficient when producing identical parts in large volumes.

Conclusion

Multi cavity and family injection molds are two types of molds for plastic parts production that are applied in modern manufacturing with their specific features and requirements. While multi cavity molds are ideal for the large production of similar items, family molds are ideal for production of the different items in small batches.

Thus, it allows understanding the distinctions between two types of molds and select the proper type of mold depending on the necessities of production, which consequently contributes to the enhancement of the production performance and the quality of the final products.

Due to the high efficiency and low unit cost of multi-cavity injection molds in molding production, multi-cavity injection molds have occupied an important position in mass production.

On the contrary, family injection molds do have some specific advantages in small-batch, multi-variety production.

In the future, with the advent of intelligent manufacturing technology, new materials and green manufacturing technology, multi cavity and family molds7 will be more conducive to improving production efficiency and product quality, and provide strong support for the development of modern manufacturing.

-

Learn about Molding Cycle : The molding cycle follows the sequence: mold closing, filling, packing, holding, cooling (solidification), mold opening, and part ejection. ↩

-

Learn about What are the Steps of the Injection Molding Process? Injection molding is a process used to make a lot of plastic parts. ↩

-

Learn about cooling system: cooling system, apparatus employed to keep the temperature of a structure or device from exceeding limits imposed by needs of safety and efficiency. ↩

-

Learn about Runner System: The Runner System is the filling system through which material travels from the injection unit into the part cavity. ↩

-

Learn about 101 Injection Molding Runner Design Guideline: A well runner design injection molding ensures that the plastic is distributed evenly into the cavities, resulting in consistent part quality and reduced waste. ↩

-

Learn about cooling system : cooling system, apparatus employed to keep the temperature of a structure or device from exceeding limits imposed by needs of safety and efficiency. ↩

-

Learn about Multi-Cavity Molds vs Family Molds: Making the Best Choice for Your Project: Both multi-cavity and family molds have some unique characteristics that should always be considered for the overall efficiency of the process. ↩