Injection molds are essential in manufacturing by shaping molten plastic into desired forms for various industries. They provide precision, speed, and cost efficiency.

Injection molds enable high-volume production by shaping molten plastic into specific forms. They ensure consistent product quality, reduce waste, and are critical in industries like automotive, electronics, and consumer goods.

While injection molds offer numerous benefits, understanding their components and design is crucial for optimizing production efficiency. Learn more about how mold design impacts your manufacturing processes.

Injection molds increase production efficiency in manufacturing.True

Injection molds allow for high-speed, high-precision production, significantly reducing cycle times and ensuring consistency across large production runs.

Injection molds are always expensive to design and use.False

While the initial cost of injection mold design can be high, the cost per part is low in high-volume production, making them cost-effective in the long term.

What is the Definition of Injection Mold?

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold cavity. It’s widely used for plastic, metal, and other materials.

Injection molding is a process where material is injected into a mold to create parts. It is efficient for mass production and offers precision and flexibility in design, making it ideal for industries like automotive, consumer products, and electronics.

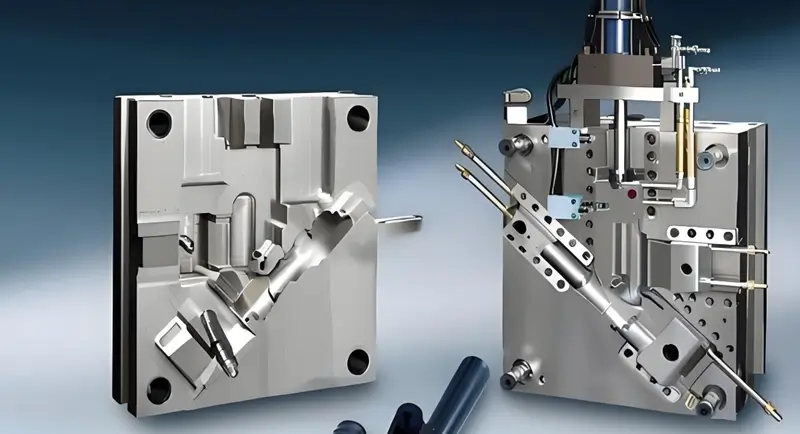

An injection mold1 is a mold that is used to make plastic products. It can make a variety of plastic products, such as plastic cups, parts, toys, and household items. It is made of a steel structure and usually has three parts: a mold base, an injection cavity, and an ejector mechanism.

The mold base is the main part of the injection mold. It can be made up of semi-fixed and removable parts. It supports and protects the structure of the entire mold. The injection cavity is where the plastic is melted and injected by the injection molding machine2to make the plastic part.

The shape and size of the plastic part are determined by the shape of the injection cavity. The ejector mechanism is used to eject the molded product from the mold after the processing is completed. It is also used to remove the mold.

Injection molding is a fast, efficient production method.True

The process enables high-speed production with minimal waste, offering rapid turnaround times for large quantities of parts.

Injection molding can only be used for plastic parts.False

Injection molding is versatile and can be used for a wide range of materials, including metals, ceramics, and elastomers, depending on the application.

What are the Classifications of Injection Molds?

Injection molds are classified into several types, each serving distinct purposes. Understanding these classifications helps optimize the injection molding process for various products and industries.

Injection molds are primarily classified into two types: cold runners and hot runners. Cold runners use external channels for material flow, while hot runners maintain molten plastic at optimal temperatures, enhancing efficiency. Other classifications include single-cavity and multi-cavity molds, based on the number of parts produced per cycle.

Single Parting Surface Injection Mold

When the mold is opened, the movable mold is separated from the fixed mold to remove the plastic parts. This is called a single parting surface mold, also known as a double plate mold. It is the simplest and most basic form of injection mold.It can be designed as a single cavity injection mold or a multi-cavity injection mold3 according to needs. It is the most widely used injection mold.

Double Parting Surface Injection Mold

The double parting surface injection mold has two parting surfaces. Compared with the single parting surface injection mold, the double parting surface injection mold has a partially movable middle plate (also called a movable gate plate, on which the gates, runners and other components required for the fixed mold are arranged) .

So it is also called a three-plate (movable plate, middle plate, fixed plate) injection mold;This type of mold is commonly used for single or multi-cavity injection molds with point gate feeding. When the mold is opened, the middle plate is separated from the fixed mold plate at a fixed distance on the guide column of the fixed mold plate to remove the condensate of the casting system from between the two mold plates.

The double parting surface injection mold has a complex structure, high manufacturing cost, and difficult parts processing. It is generally not used for the molding of large or extra-large plastic products.

Injection Mold With Side Parting Core Pulling Mechanism

When the plastic part has a side hole or side concave, you need a core or slider that can move sideways to mold it. After injection molding , the movable mold plate first moves down a bit, and then the inclined part of the bent pin fixed on the fixed mold plate pushes the slider to move out. At the same time, the push rod of the demolding mechanism pushes the push plate to take the plastic part off the core.

Injection Mold with Movable Molding Parts

Because of the special structure of some plastic parts, the injection mold needs to have movable molding parts, such as movable punches, movable cavities, movable inserts, movable threaded cores or rings, etc., which can move out of the mold with the plastic part during demolding4 and separate from the plastic part after demolding.

Automatic Thread Stripping Injection Mold

For plastic parts with threads that need to be automatically ejected, you can put a rotating thread core or thread ring on the mold, and use the mold opening action or the rotation mechanism of the injection molding machine to drive the thread core or thread ring to rotate, or you can set up a special transmission device to remove the plastic parts.

Runnerless Injection Mold

Runnerless injection molding refers to a method of using runner adiabatic heating to keep the plastic between the injection molding machine nozzle and the cavity in a molten state, so that when the mold is opened to take out the plastic parts, the pouring system does not condense. The former is called an adiabatic runner injection mold, and the latter is called a hot runner injection mold.

Hot runner molds improve part consistency.True

Hot runner systems maintain the plastic at the ideal temperature, ensuring uniform flow and improving the consistency of molded parts.

Cold runner molds are always cheaper than hot runner molds.False

Although cold runner molds have a lower upfront cost, hot runners can reduce material waste and improve efficiency, which may lower long-term production costs.

What are the Steps for Making an Injection Mold?

Creating an injection mold involves several crucial steps to ensure precision and functionality, from initial design to production.

The steps to make an injection mold include design, material selection, mold fabrication, testing, and refining. Proper design ensures the mold functions efficiently, reducing errors and improving part quality in the final product.

Process Analysis of Plastic Products

Before designing the mold, the designer should fully analyze and study whether the plastic product conforms to the principle of injection molding processing, and needs to carefully negotiate with the designer of the product to reach a consensus.

This includes necessary discussions on the shape, dimensional accuracy and appearance requirements of the product, and try to avoid unnecessary complexity in mold manufacturing.

Mold Structure Design

To make a good mold, you need good equipment, good workers, and good design. Good design is especially important for complex molds. Good design is 80% of the mold. A good design is one that meets the customer’s requirements and is easy to make, cheap to make, and fast to make.

To do this, you need to not only fully understand the customer\’s requirements, but also understand the injection molding machine, mold structure, processing technology, and the processing capabilities of the mold factory itself.

So, to improve the level of mold design, you need to do the following: understand every detail in each set of mold design and understand the purpose of each part in the mold. When designing, refer to previous similar designs, understand the situation during its mold processing and product production, and learn from the experience and lessons.

To deepen the relationship between the mold and the injection molding machine, learn more about the working process of the injection molding machine. Go to the factory to understand the processing technology of the processed products and recognize the characteristics and limitations of each processing.

Understand the trial results and mold modification of the molds designed by yourself and learn lessons. Try to use the mold structure that was relatively successful in the past when designing. Learn more about the impact of mold water entry on the product. Study some special mold structures and understand the latest mold technology.

Determine the Mold Material and Select standard Parts

When you choose the mold material5, you should not only consider the accuracy and quality of the product, but also combine the actual processing and heat treatment capabilities of the mold factory to make the right choice. In addition, in order to shorten the manufacturing cycle, use existing standard parts as much as possible.

Parts Processing and Mold Assembly

When designing a mold, it’s important to make sure that the structure is reasonable and the tolerances are appropriate. But even if you do that, if the mold isn’t accurate, if the parts aren’t processed correctly, and if the mold isn’t assembled correctly, you’re not going to get a good part. So, the choice of processing accuracy and processing methods is the most important thing in mold manufacturing.

The dimensional error of molded products mainly consists of the following parts: The manufacturing error of the mold is about 1/3. The error caused by mold wear is about 1/6. The error caused by uneven shrinkage of molded parts is about 1/3. The error caused by the inconsistency between the expected shrinkage and the actual shrinkage is about 1/6.

So, to reduce the manufacturing error of the mold, first improve the processing accuracy. The use of CNC machine tools has solved this problem well. In addition, to prevent errors caused by mold wear and deformation .

When the mold has high processing accuracy requirements and large product output, key parts such as the cavity and core should be quenched. In medium and large molds, in order to save materials and facilitate processing and heat treatment, the mold design should try to use a mosaic structure.

To solve the problem of uneven shrinkage of molded parts and the inconsistency between expected shrinkage and actual shrinkage, the manufacturing tolerance of the mold is generally selected as 1/3 of the product tolerance during mold manufacturing. The purpose is to leave a large adjustment space for the subsequent molding process to solve the errors caused by the molding process.

Mold Trial

From design to assembly, molds only complete 70% to 80% of the manufacturing process. Errors caused by inconsistent expected and actual shrinkage, smooth demolding, cooling effects, and the size, position, and shape of the gate all affect product precision and appearance.You gotta test the mold by trying it out. So, the trial mold is a must-do step to see if the mold is good and to pick the best way to make it.

Injection mold creation requires extensive testing.True

Testing ensures that the mold operates correctly, with no defects, before full-scale production begins.

Injection molds can be made from any material.False

Injection molds are typically made from durable materials like steel or aluminum to withstand the high pressures and temperatures of the molding process.

What is the Function of Injection Mold?

Injection molds are tools used to create precise, high-quality plastic parts through a molding process. They play a key role in shaping products efficiently for various industries.

Injection molds allow manufacturers to produce high-precision plastic parts in large volumes. They are essential for creating products like automotive components, household items, and electronics. The process is cost-effective, with minimal waste and high consistency.

Produce High-Precision and High-Efficiency Industrial Products

The mold can ensure the accuracy and consistency of the product during processing, thus improving the quality of the product.

The mold can control the size and shape of the product accurately to meet various high-precision manufacturing requirements. In some fields, such as aviation and national defense, the importance of mold precision control is particularly prominent.

The mold can make the product form a specific shape and size during the production process, so as to ensure the accuracy and efficiency of the product. For example, auto parts, mobile phone shells and other parts that require high precision all need to be processed using molds.

Improve Production Efficiency and Reduce Costs

The mold can make a lot of industrial products at once and make them faster. It can also make things better than people can. It can make things the same every time and make them right.

Molds help control manufacturing costs. First, molds can be reused, so you don’t have to buy or make the same part over and over. Second, mass production can lower the cost of each part. Finally, molds can help you find better ways to make things.

Another big benefit of using molds for production and processing is that it can greatly improve production efficiency. The use of mold processing can reduce manual operations and realize production automation, thereby achieving the goal of saving labor costs and improving production efficiency.

Purpose of Improving Efficiency

The mold can process the workpiece up and down, improve the processing speed and efficiency, and reduce the production cost. For example, when producing plastic products, using molds can be faster and more efficient than manual molding.

Maintain Product Consistency And Repeatability

Because the shape and size of products made by molds are consistent, the consistency and repeatability of products can be maintained. This is very important in the process of large-scale production to ensure that each product has the same quality and characteristics.

Ensure Quality And Safety

Using molds can help ensure that the quality of products is stable and consistent. Molds can make parts with high precision and complex shapes, so that the products meet the design requirements perfectly. In addition, using molds can reduce the defective rate, improve the yield rate of products, and ensure the quality of products.

Using molds can help prevent product quality issues like size differences and surface flaws. Plus, using molds for production and processing can make the work environment safer and reduce the chance of accidents.

Produce Various High-Precision Parts

Molds can make all kinds of high-precision parts, from a few millimeters to several meters. For example, all kinds of small parts used in automobile engines, interior parts, door locks, electronic devices, mobile phones and other products need molds to be processed accurately.

Make Molds of Complex Shapes

Molds can also make molds of various complex shapes. These molds are used to manufacture various high-tech products, such as aircraft components, medical devices, electronic components, etc.

Injection Molded Products

Injection molding is the process of injecting molten plastic or rubber6 into a mold and obtaining molded products after it solidifies. It is one of the most commonly used processing methods in today\’s industrial production.

Injection molding can produce large quantities of plastic or rubber products in a short time. The mold can be applied to products of various shapes and specifications, which greatly improves production efficiency.

Realize Production Automation

Molds can make a lot of stuff fast and you can use them over and over again to make a lot of stuff.

Using molds can turn a lot of people work into machine work, make things by themselves, and make things faster.

Promote Industrial Development

Molds are one of the basic facilities of industrial manufacturing, and the level of mold manufacturing directly affects the development of national industrial manufacturing. With the development of the economy and the increasing quality requirements of industry, the demand for the mold industry is also increasing.

The development of the mold manufacturing industry can not only promote the development of the manufacturing industry, but also cultivate talents, improve the technical level, and drive the development of related industries.

Injection molds are essential for mass-producing plastic parts.True

Injection molds enable the mass production of high-precision plastic parts efficiently, making them essential in industries like automotive and consumer goods.

Injection molds are only used for large-scale production.False

While injection molds excel in large-scale production, they can also be used for prototyping and small-batch manufacturing, providing flexibility for various production needs.

What are the Main Applications of Injection Molds?

Injection molds are critical in various industries, shaping products with precision. They are used to produce items ranging from automotive parts to medical devices, ensuring efficiency and high-quality production.

Injection molds are used in diverse sectors, including automotive, consumer goods, and electronics. They provide accurate, high-volume production of parts such as gears, housings, and medical components. Benefits include fast production times and cost efficiency.

Molds are widely used in many industrial fields. For example:

Automobile Manufacturing Industry

Different molds are used to process various parts in automobiles, such as engine parts, body parts, interior parts, etc.

Many parts used in the automotive manufacturing industry need to be processed using molds, such as car bodies, hoods, wheels, etc.

Home Appliance Manufacturing Industry

Many home appliances, like TV shells, refrigerator shells, washing machine shells, etc., need to be molded using molds.

Home appliances, like plastic shells, metal shells, and other accessories, also need molds for processing and production.

Electronic Industry

Electronic products require molds to process and produce various plastic shells, metal shells, keyboards, circuit boards, and so on.

Construction Industry

In the construction industry, molds are needed to process and produce various types of cement formwork, ceiling panels, and so on.

Aviation Manufacturing Industry

In the aviation manufacturing industry, there are many complex parts that need to be processed using molds, such as aircraft fuselages, engine parts, and so on.

Injection molds are used in automotive, medical, and consumer goods industries.True

Injection molding is ideal for producing parts such as automotive components, medical devices, and consumer products due to its efficiency and cost-effectiveness.

Injection molds are only used for plastic products.False

Injection molds can be used for a variety of materials, including metals and elastomers, making them versatile in different industries.

Conclusion

In products like electronics, cars, engines, instruments, electrical appliances, meters, home appliances, and communications, 60%-80% of the parts depend on mold molding.

The role of injection molds is mainly to produce high-precision and high-efficiency industrial products, improve production efficiency and reduce costs, maintain product consistency and repeatability, ensure quality and safety, produce various high-precision parts, manufacture complex-shaped molds, injection molding products, realize production automation, and promote industrial development.

-

Learn about Everything You Need to Know about Plastic Injection Molds: Plastic injection molds shape plastic by injecting molten material into a mold cavity, where it cools and solidifies into a part. ↩

-

Learn about Injection molding machine :Injection molding machine consists of two main parts, an injection unit and a clamping unit. ↩

-

Learn about Single-Cavity vs. Multi-Cavity Injection Molding: Injection molding may be facilitated by means of a single- or multi-cavity mold. ↩

-

Learn about Demolding in Injection Molding: Techniques and Best Practices : Demolding of plastic parts is the last step in the injection molding process. ↩

-

Learn about How to choose the right injection mold materials : The right materials ensure that your parts meet the required standards, exhibit excellent finish . ↩

-

Learn about Everything You Need to Know about Plastic Injection Molds: Plastic injection molds shape plastic by injecting molten material into a mold cavity, where it cools and solidifies into a part. ↩