Injection molding machines can create threaded molds, a process commonly used for producing parts with internal or external threads in industries like automotive, consumer goods, and medical devices.

injection molding machines can mold threaded molds. Special molds with inserts or core pins are used to form threads during the injection process. This method is efficient and ensures high precision in threaded parts.

While molding threaded parts in injection molding is possible, selecting the right mold design and material is key for achieving precise, functional threads. Dive deeper into how threaded molds are created and optimized for production.

Injection molding machines can mold threaded molds.True

Injection molding machines use specialized molds with inserts or core pins to form threads accurately during the molding process.

Injection molding machines are always the best option for threaded parts.False

Other processes like die casting or CNC machining may be more suitable for certain threaded components, depending on material, precision, and production volume.

What is Injection Molding Technology?

Injection molding is a manufacturing process used to produce high-volume plastic parts with precision, efficiency, and repeatability. It’s essential across industries like automotive, medical, and consumer goods.

Injection molding technology involves injecting molten plastic into a mold to create precise parts. It offers high efficiency, low waste, and is widely used in automotive, electronics, and medical device production.

Injection molding is accomplished by injecting molten plastic material into molds. Cooling and solidification follow, before finished plastic products can be released from the mold. Heating plastics, plasticizing, injecting molten plastic materials into injection molds, applying pressure, cooling molded items, and then releasing them from the mold are all part of this process. The injection molding process has the advantages of short molding cycles, high production efficiency, and stable product quality, making it one of the most widely used plastic molding processes today.

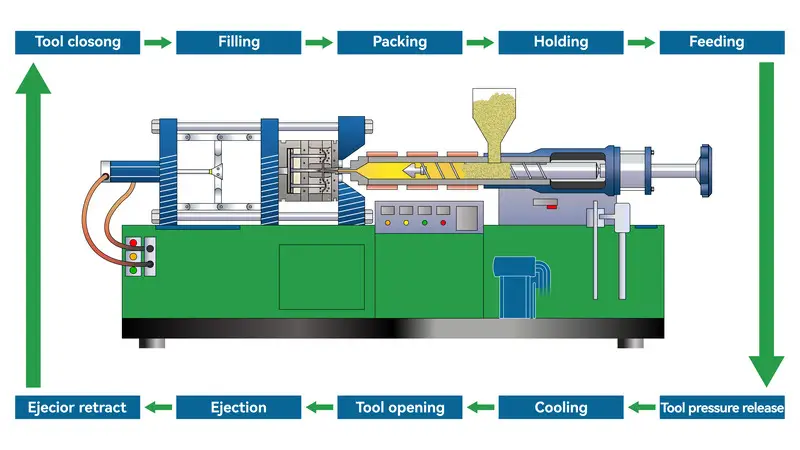

Injection Molding Process

The injection molding process primarily includes the following steps

-

Heating the Plastic: The plastic raw material is melted through the help of a heating gadget to get molten plastic raw material. Normally, many of injection molding machines possess the screws or plungers that push the plastic material forward while at the same time heating it.

-

Plasticizing: During heating, the material, plastic is plasticized by the action of the screw or the plunger to the required viscosity and flow needed for injection.

-

Injection: The plasticized plastic material circulates through the screw and is pushed into the mold cavity1 by hydraulic pressure. When injecting plastic material, the molten material fills the mold and forms the desired shape in it.

-

Holding Pressure: After the injection is completed, a certain pressure is maintained to accommodate the reduction in material volume during cooling, so as to have the appropriate product size and surface finish.

-

Cooling: The plastic material in the mold has thus cooled and solidifies to the final product. The cooling time2 is in direct proportion to the plastic material characteristics and the thickness of the manufactured good.

-

Demolding: Finally, the plastic injection mold is usually opened once the product has cooled down to the desired temperature after which the formed plastic product is released.

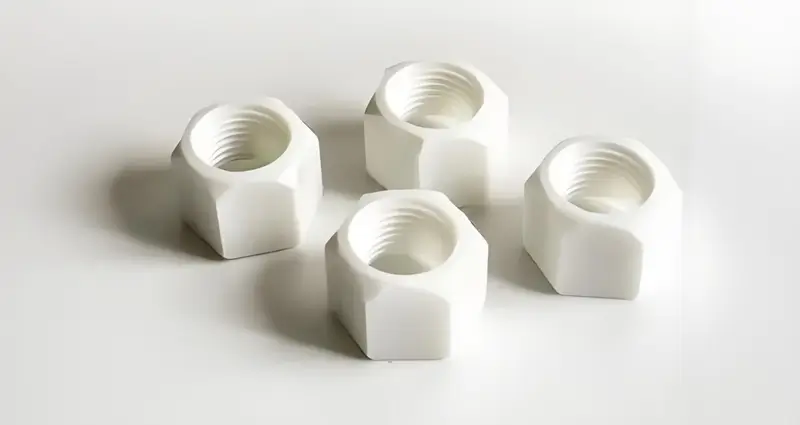

What is a Threaded Mold?

Threaded molds are used in injection molding to create parts with internal or external threads, such as bolts and nuts, ensuring a precise fit and function.

A threaded mold is designed to form parts with threads, either internal or external. It features inserts or built-in threading mechanisms to create components that require tight fits, such as screws or nuts, during the injection molding process.

Key Design Points of Thread Molds

Key design points of threaded molds include

-

Thread Geometry: Firstly it is necessary to define type of thread, internal molded threads or external threads, pitch, angle, depth of thread and etc. This geometry of the thread type has a considerable impact on connecting efficiency and the product’s service life.

-

Draft Angle: Since it is possible to have difficulties with the demolding of threaded products, the basic draft angle3 is usually given to inner and outer thread surfaces during their design. When positioning the draft angle, it is necessary to assess the details of the thread depth and the framework of the mold.

-

Parting Line Design: It should also be reasonably designed for the parting line of the mold in order to allow it to part easily during injection molding as well as demolding. Parting line4 (single parting surface mold or double parting surface mold) may also have different designs in molded articles particularly when the threads are compounded in a single unit for improved molding quality.

-

Rotating Demolding Mechanism: For making easier to demolding, there can be set a rotating demolding structure within the mold, it could revolve together with the threaded product within the mold for opening the mold and demolding5 without any scratch on the product.

Threaded molds are essential for producing threaded parts.True

Threaded molds include inserts or mechanisms that form threads in the molded part, ensuring the correct fit and functionality.

Threaded molds are always more expensive than standard molds.False

Threaded molds may have a higher upfront cost due to their complexity, but their long-term efficiency and ability to produce threaded components accurately can offset the initial investment.

What are the Factors That Affect the Feasibility of Thread Mold Injection Molding Machines?

The feasibility of thread mold injection molding machines depends on several key factors, including mold design, material choice, and machine capabilities. These elements influence production efficiency and product quality.

Factors impacting thread mold injection molding feasibility include the complexity of the thread design, mold cooling efficiency, material flow, and the type of injection molding machine used. Proper design ensures high-quality thread parts with minimal defects.

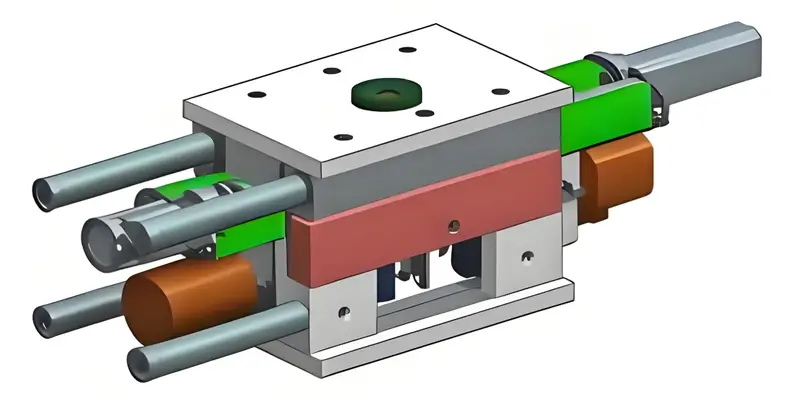

Mold Design

If you want to produce perfect threaded injection products, it is very important to have a good thread mold. However, conventional mold design is not suitable for thread molding and requires something extra, so technologies such as parting line design, rotary demolding mechanisms, and moving threaded core are needed to achieve thread molding and demolding. For example, a rotatable moving mold is used, which rotates with your threaded product during the mold opening process, so lossless demolding can be achieved. The application of these technologies can not only improve the manufacturing accuracy of thread molds, but also improve production efficiency.

-

Parting Line Design: When engineers accurately determine where the parting line should be and what it should look like, they help ensure that the mold will separate smoothly when it’s time for both injection molding and de-molding. A good parting-line design will cut down on wear and tear suffered by the mold, and extend its useful life as well.

-

Rotating Demolding Mechanism: To prevent damage while demolding parts, mold can be designed to rotate along with threaded product as it opens. Rotating demolding mechanism’s design must account for thread pitch, geometry and rotational speed, all of which affect how smoothly this critical step happens.

-

Moving Core: When a mold has a moving core it can make threads as well as remove them by making the core move. The design of the moving core needs to consider its motion trajectory, speed, and precision to ensure the molding quality and smooth demolding of the thread.

Equipment Requirements

To successfully inject threaded molds, the injection molding machine must have specific technical characteristics. These include sufficient clamping force to ensure the stability of the mold during the molding process. Secondly, the screw design not only meets the requirements of plastic melting and injection, but also controls the speed/pressure, and the control system can accurately adjust various parameters in the molding process to ensure the consistency of product quality.

-

Clamping Force: The clamping force of the injection molding machine must big enough to guarantee that the mold is stable when the molding process is being done. In general, the clamping force of the threaded molds is higher compared to the usual molds because constructions of the threads demand higher injection pressure and clamping force in molding.

-

Screw Design: When designing and selecting the screw of an injection molding machine it is important to consider factors such as melting of the plastics and injections. For example, the length of the screw, diameter, pitch as well as the depth of the threads all require optimal configuration depending on the type of the plastic material and molding parameter.

-

Control System: It is vital for the control system of the injection molding machine to regulate several factors when molding; including injection pressure, injection speed, mold temperature, and cooling time. Thus, it is possible to have accurate and intense control over these parameters so as to warrant the right size and proven surface finish of the threaded products.

Material Selection

The material decision that is used for injection molding has a significant influence on the molding effect of thread molds. Typically, the injection moldings materials include polypropylene (PP), polyethylene (PE), polyamide (PA), polycarbonate (PC) and the like, the characteristic of these material are showing flowing, abrasion, anticorrosive properties which meet the requirements in creating thread structure. Moreover, there are issues, the heat resistance, the chemical resistance, the strength and durability in relation to the surrounding environment and constraints of the product.

-

Polypropylene (PP): Polypropylene has relatively high chemical resistance, heat resistance, and electrical self mobilization and can be used in the making of plastic goods. Polypropylene has good flowability, which can allow the creation of molding the threaded structure.

-

Polyethylene (PE): Polyethylene is a notable plastic since it has low chemical corrosion and equally it can be used in low temperatures it mainly used to produce food packages and containers for chemicals. Polyethylene has a good flow characteristic; hence it can be easily molded to achieve threaded forms.

-

Polyamide (PA): Polyamide includes good mechanical characteristics and wears resistance, and it is applied in the production of car parts and home appliances. Polyamide also has good flowability and, thus, can easily be molded into the intended threaded structures.

-

Polycarbonate (PC): Polycarbonate belongs to the thermo plastic series that has the characteristic features such as good clarity, high heat resistance, and good impact strength; it is widely used for manufacturing optical equipment and safety accessories. On the aspect of flowability, polycarbonate has very good properties, and therefore can easily be used to create threaded structures.

Process Parameter Control

Some of the process control parameters that should be followed especially during the injection molding of threaded molds include the following. Depending on the kind of material to be injected and the design of the mold, injection pressure, injection speed, mold temperature, cooling time and other factors have to be properly adjusted. For the kind of products having complicated thread forms, the effective molding conditions have to be identified in collaboration with trial molding and process fine tuning so as to achieve high precision and quality.

-

Injection Pressure: It controls the flowability of the plastic material and molding quality of the product thus can be considered as an essential factor of injection pressure. More injection pressure is needed when the injection molding threads are many and intricate in order to enable the plastic material to enter the mold cavity.

-

Injection Speed: The injection speed is actually a determinant of the flow state of the plastic material as well as the surface finish of the product. It can also be said that if the injection speed is reasonable, then surface defects and molding quality will be minimized.

-

Mold Temperature Control: Cooling of the mold is an essential parameter in the manufacture of the plastic material in relation to the cooling rate and the dimensional accuracy of the material. Thus, to achieve the required dimensions of accuracy and quality of the surface of the product, it is necessary to put into practice proper regulation of the mold temperature.

-

Cooling Time: This time consequently determines the cooling and the solidification process of the product being manufactured. If appropriate, cooling time should be allowed to reduce deformities and internal stress which will have an impact on the molding quality.

Material flow affects thread mold injection molding feasibility.True

Proper material flow ensures consistent thread formation and minimizes defects during the molding process.

Complex mold designs guarantee the success of thread molding.False

While complex designs can enhance precision, they may increase production cost and time, making simplicity sometimes more effective.

What are Some Case Studies on the Practical Application of Injection Molding Thread Molds?

Injection molding thread molds offer efficient solutions for producing threaded parts with high precision. Case studies show how this technology is applied in various industries.

Thread molds in injection molding create precise, durable threads for a range of products, including automotive, medical, and consumer goods. They ensure high-quality production with minimal post-processing.

Bottle Cap Production

Threaded molds are used in production of bottle caps, it is one of the most commonly used application part. Due to the sealing and screwing functions with the bottle body, the thread structures of bottle cap products need to be very special and specific. High-efficiency production of bottle caps can be achieved by optimizing mold design and injection molding processes.

-

Mold Design: For bottle cap molds, many cavity molds are often employed to help raise the productivity. The design of the mold also requires the application of the precision and interchangeability of the threads of the bottle cap to fit well the sealing characteristics of the bottle body.

-

Injection Molding Process: In injection moulding of the bottle caps one has to have great control over the injection pressure6, injection speed, mold temperature7, cooling time etc. By doing so, the parameters such as molding quality of bottle caps and overall production rate might be enhanced.

-

Automated Production Line: Current industries of making bottle cap through the use of bottle cap production lines entail the use of automatic feeding, demolding, and inspection to enhance operations and result in quality productions.

Automotive Parts

In the automotive sector, the common threaded parts embrace bolts, nuts, and connectors. These parts do not only need strength and durability, but they also need to provide good assembly characteristics. High- performance materials and precise injection molding can also be adopted in creating threaded parts which can satisfy the requirement of car manufacturing industries. Integration of hot runner molds facilitates the production of durable and precise threaded components crucial for automotive applications.

-

Material Selection: Common automotive grouped elements are high-performance engineering plastics like polyamide (PA) and polycarbonate (PC). Such materials have rather good mechanical characteristics and high hot strength, the use of which will be appropriate in car parts industry.

-

Mold Design: The molds for automotive threaded parts have to focus on the geometry and assembly response of those parts. Precision mold design can guarantee the dimensional tolerance of the parts and assembly characteristics.

-

Injection Molding Process: The specific parameters that are significant to the injection molding process of automotive threaded parts include the injection pressure, injection speed, mold temperature, cooling time among others. Thus, adjusting these process parameters can locate and correct sources that cause bad molding quality and lower efficiency of the parts.

Household Appliances

Another segment within the household appliances also involves threaded structures for instance knobs on the washing machines and connectors on the blenders. Apart from the exterior, these parts require an appealing appearance as well as satisfactory functionality and product sturdiness. It could be reasonable to estimate that production of the high-quality household appliance threaded parts does not require significantly stretched but adequate mold design and well-devel oped injection molding technologies. Hot runner injection mold ensure that these parts meet design specifications with high precision and efficiency.

-

Material Selection: In the case of home appliances industry, the threaded parts in households appliances and RAC are manufactured from polypropylene (PP) and polyethylene (PE). It has a good flowability and mechanical property of the material that is suitable to be used in the household appliance threaded parts.

-

Mold Design: Threads which are created using molds used in the production of household appliance threaded parts should present nice looking part as well as to serve the intended function. Attention to creating a precise mold may help enhance the looks of the parts in question as well as their usability.

-

Injection Molding Process: The injection molding process of household appliance threaded parts should well control the injection pressure, injection speed, mold temperature, cooling time and so on. These process parameters make it possible to increase the molding quality and production efficiency of the parts.

Thread molds improve thread accuracy in injection molding.True

Injection molding thread molds create precise, uniform threads, reducing post-processing and increasing the overall quality of the product.

Thread molds are only suitable for simple, non-complex threads.False

Thread molds can be designed to create both simple and complex threads, making them versatile for various applications in different industries.

Conclusion

As for the injection molding of threaded molds, injection molding machines can do it, and the application areas include bottle caps, automobile parts, home appliances, and other industries.

Threaded products of good quality can thus be developed through a proper choice of the mold design, selection of suitable injection molding materials8, and effective control of the parameters. In the future, the application fields of injection molding of threaded molds will expand further, and the development trend will be further developed in the direction of high precision, intelligence, and environmental protection .

-

Learn about Mould Cavity : The mold cavity is meticulously crafted to precisely match the dimensions of the desired product. ↩

-

Learn about The importance of cooling time in injection molding : cooling time will directly affect the molding cycle and output of plastic products. ↩

-

Learn about Draft Angle Guidelines for Injection Molding : Draft is a taper applied to the faces of the part that prevent them from being parallel to the motion of the mold opening. ↩

-

Learn about Parting Line Injection Molding : The parting line is where these two mold halves separate after an injection molding cycle is complete. ↩

-

Learn about Understanding the Demolding Process in Injection Molding: Key Steps and Best Practices : The demolding process is the final stage of the molding process. ↩

-

Learn about Injection Pressure : The injection pressure refers to the pressure at which the refrigerant is injected to the compressor. ↩

-

Learn about Mould Temperature : The mould temperature is probably the most important temperature in terms of quality and this affects quality in many ways. ↩

-

Learn about What Types of Plastic Materials are Best Suited for Injection Molding? Select the material best suited for a particular application by considering factors such as strength, heat resistance, cost, appearance, etc. ↩