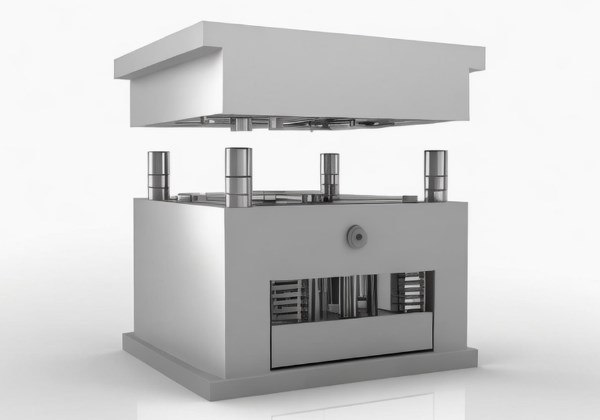

Plastic injection molding refers to the process of injecting molten plastic into a plastic product mold under pressure and cooling it to obtain the desired plastic parts. Injection molding processes is a widely utilized manufacturing technique, particularly in sectors like car manufacturing, consumer gadgets and medical equipment.

One important variable here is injection speed, which simply measures how long it takes for an injection molding machine to force hot liquid plastic into the mold itself. This is a critical factor that influences both production efficiency and product quality. As the core component of the injection molding process, the design and quality of the injection mold directly impact the injection speed.

This article delves into how injection molds affect injection speed, examining mold design, material selection, manufacturing processes, mold temperature control, runner design, and more.

The Impact of Mold Design on Injection Speed

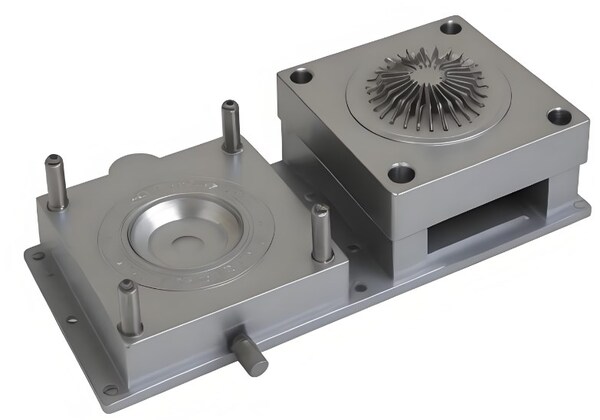

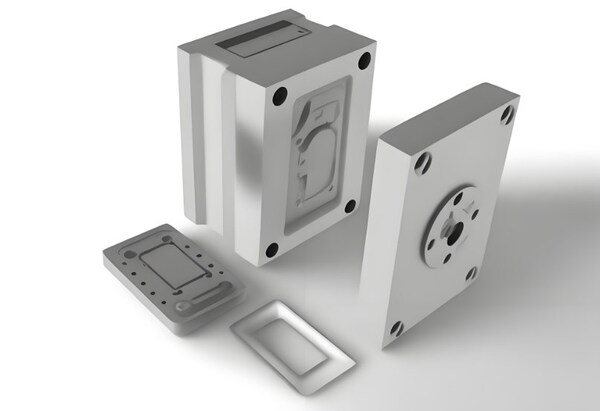

Mold Cavity Design

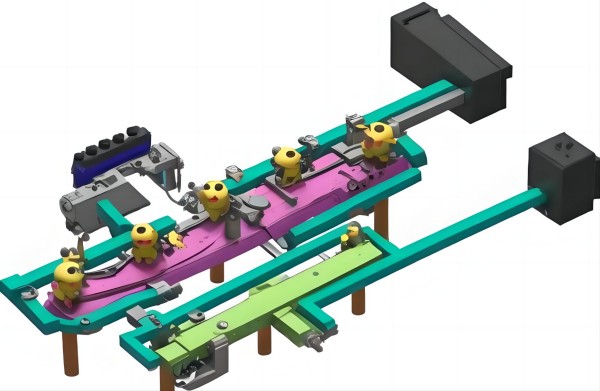

Cavity layout is the key to injection mold design. Good design can greatly increase the injection speed, while poor design will not only reduce the injection speed, but also may cause defects during the injection process or prolong the injection time.

1. Cavity Quantity: When there are multiple cavities in a mold, multiple parts can be produced at the same time. This means that the work can be completed faster, which improves production efficiency. If you try to make too many things at the same time, there may also be problems with the work of the mold (excessive injection pressure), making it more challenging to control pressure and temperature during the injection process. Therefore, it is critical for designers to balance production efficiency and process complexity when creating multi-cavity molds.

2. Cavity Arrangement: How the cavities are arranged impacts both how fluid plastic flows and the resistance it encounters. When they’re laid out well, there can be less resistance to flow, and high injection speed. Usually, people use symmetrical layouts so each cavity fills at the same rate.

Mold Structure Design

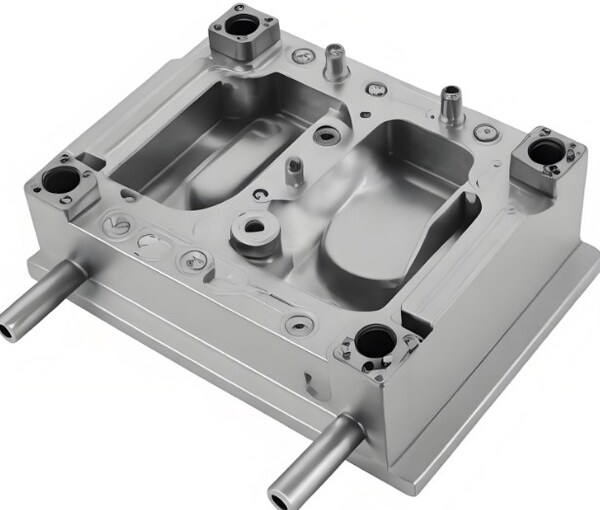

Mold structure design encompasses the parting surface, gating system, cooling system, and venting system.

1. Parting Surface Design: The parting surface is the contact surface where the mold opens and closes. If parting surfaces are designed well it will cut down on how long molds are open or shut for, make them last longer before repairs are needed and speed up injection molding too. Generally, the parting surface should be designed as flat as possible to minimize machining difficulty and wear.

2. Gating System Design: The gate serves as the passage for molten plastic to flow into the cavity. Injection speed can be improved with a well-planned gate. Direct gates, pin gates and fan gates are some varieties used. Choosing the right size and type leads to less resistance to flow as the part is being filled, increasing filling speed.

3. Cooling System Design: The design of the cooling system has a big effect on how fast you can inject material. Cooling time often accounts for more than half of the entire injection cycle, so an efficient cooling system can considerably shorten the injection cycle. Common cooling methods include water cooling and oil cooling. The layout and size of cooling channels must be well-designed to ensure uniform cooling and rapid heat dissipation.

4. Venting System Design: In order to prevent defects like burns and bubbles by taking air and volatiles out of the cavity, usually use a venting system. If designed well, this system can improve how fast we inject materials and the overall quality of the products that result. Typically, vent grooves are placed on the cavity and parting surface, or vent plugs and vent holes are used for venting.

The Impact of Mold Materials on Injection Speed

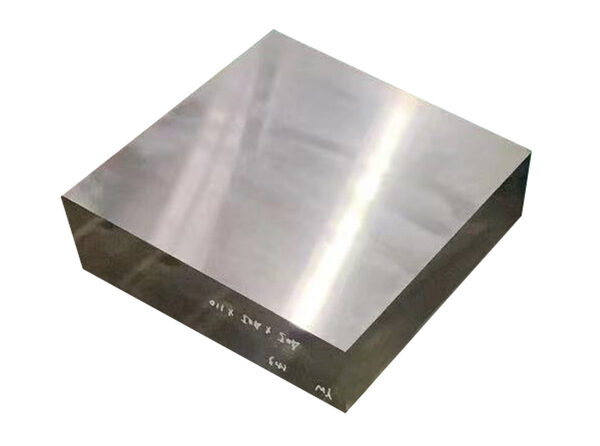

Mold Steel Selection

The choice of mold material directly affects the mold\’s lifespan, machining precision, and injection speed. Common mold materials include mold steel, aluminum alloy, and copper alloy.

1. Mold Steel: Mold steel is known for its high strength, hardness, and resistance to wear, all key properties when making molds in large quantities. There are several types of mold steels available including P20, H13 and S136. Although it doesn’t conduct heat very well which restricts how quickly heat can be removed by cooling, there are treatments such as chrome or titanium plating that can help improve both wear-resistance as well as corrosion resistance too.

2. Aluminum Alloy: Aluminum alloy possesses great machinability and thermal conductivity, making it suitable for prototype molds as well as small batch production. 6061 and 7075 are among the most common types used. While these molds allow for faster cooling so injection speeds can be increased, they are not as strong or wear-resistant as steel, making them suitable for lower-demand products.

3. Copper Alloy: Copper alloy has great heat conduction and can withstand corrosion well. That’s why mold components needing quick cooling—like gate inserts or cooling inserts—are often made from copper alloys. Copper alloy molds cool efficiently, significantly increasing injection speed, but they are more expensive and usually combined with mold steel or aluminum alloy.

Mold Surface Treatment

Surface treatment enhances mold performance. Common surface treatments include chrome plating, titanium plating, nitriding, and carburizing.

1. Chrome Plating: This process boosts surface hardness and wear resistance while also reduces friction, all of which can help speed up injection times. Most molds will have a chrome layer measuring between 0. 01-0. 1mm applied to them.

2. Titanium Plating: With a thickness ranging from 0. 001 to 0. 01 mm, titanium plating can be used on mold components that are exposed to high levels of wear and heat. This plating also resists corrosion well, a quality which extends both the life of molds and how quickly manufacturers can inject into them.

3. Nitriding: Nitriding enhances surface hardness and wear resistance, prolonging mold lifespan. The nitriding layer usually ranges from 0.1 to 0.5 mm in thickness, suitable for high-strength, high-hardness molds.

4. Carburizing: By boosting surface hardness and wear resistance, carburization improves how long a mold can be used before it fails from fatigue. This treatment creates a hardened layer about 0. 5 mm to 2 mm thick, so mass-producing molds becomes more cost-effective.

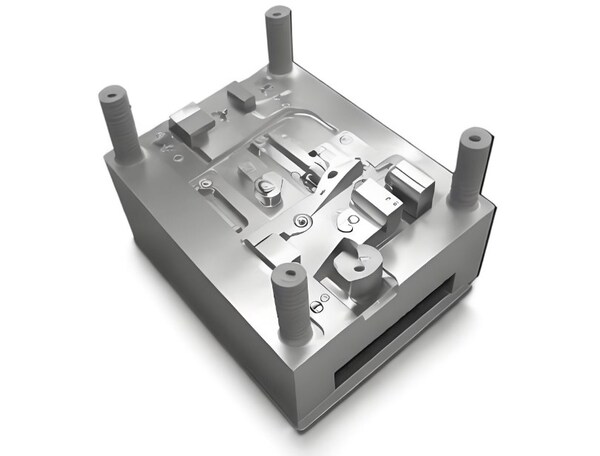

The Impact of Mold Manufacturing Process on Injection Speed

Precision Machining Technology

Precision machining is crucial for improving mold machining accuracy and surface quality. Common precision machining techniques include CNC machining, EDM, and laser machining.

1. CNC Machining: This process enables the creation of highly accurate, efficient and flexible molds, including those with intricate shapes. It is very good at improving both surface quality and overall precision during mold making. Most types of mold can be made using CNC machines but they are especially useful when an item has complex features or if it needs to be produced to a very high tolerance indeed.

2. EDM: Machining of high-hardness, high-strength mold materials like mold steel and carbide is suitable for EDM. It can produce complex mold shapes with high precision and good surface finish, but it is less efficient, typically used for mold finishing and repair.

3. Laser Machining: Laser machining enables the processing of intricate mold shapes and micro features with high precision, efficiency, and without contact. Tasks such as laser engraving and laser cladding (which can be useful for treatments like surface finishing) are also possible, making this technology ideal when working on tooling at the tiny end of things.

Rapid Prototyping Technology

Rapid prototyping technology manufactures molds or mold prototypes directly by layering materials. Common rapid prototyping technologies include stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM).

1. Stereolithography (SLA): SLA technology works by using lasers to harden photosensitive resin layer by layer so as to build up materials and create prototypes of molds with very high precision. While it is possible to use SLA for producing prototype molds where either batch sizes are small or complex shapes are required , there are drawbacks: its material selection is limited, and mechanical performance is poor.

2. Selective Laser Sintering (SLS): Selective Laser Sintering (SLS) technology builds up materials by layering powdered materials that the laser fuses together. This process creates mold prototypes with impressive strength. SLS is suitable for manufacturing complex mold shapes and small to medium batch production prototypes, with a wide material selection but poor surface quality requiring post-processing.

3. Fused Deposition Modeling (FDM): By heating thermoplastic materials to create layers, FDM technology produces high-strength mold prototypes. While this method is good for making medium-complexity molds as well as small-batch-production prototypes, its precision during machining is not very high so surfaces come out poorly finished.

The Impact of Mold Temperature Control on Injection Speed

Mold Temperature Impact on Injection Speed

Controlling mold temperature is crucial when it comes to injection speed – get it right, and things will run faster, with better product quality. If melt temperature are too high or low, though, flow rate and cooling times for the plastic being melted can be affected, this in turn alters how quickly items can be made using injection molding machines.

1. High Mold Temperature: When the mold temperature rises too much, it makes molten plastic cool down more slowly. This extends both cooling times and injection molding cycle, so injection speeds are reduced. Moreover, high mold temperatures can lead to surface faults or distortion for example flash or warpage.

2. Low Mold Temperature: Low mold temperatures can impede the movement of melted plastic, thus slowing down production speed as well as creating defects like cold lines or incomplete filling, which not only affect quality but also slow down how quickly things can be made.

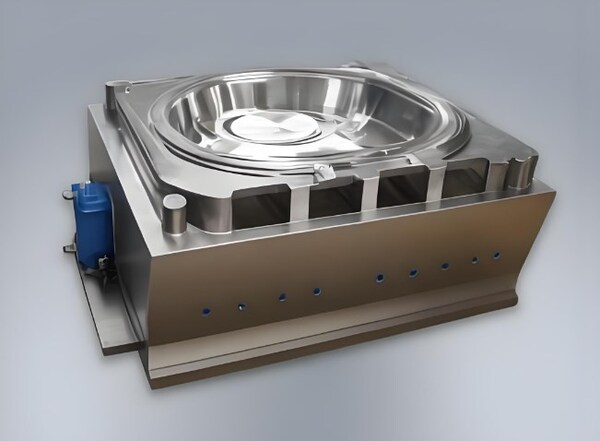

Mold Temperature Control System

To maintain mold temperature within a reasonable range, molds typically incorporate temperature control systems. Common mold temperature control systems include:

1. Water Cooling System: In the water cooling process, cooling channels inside the mold carry water around it to remove heat and lower the temperature. This is both efficient and cheap when compared to other methods for controlling how hot or cold things are when they\’re being made with injection molds, which is why more than anything else these systems are used overall.

2. Oil Cooling System: In order to cool molds, oil cooling runs cooling oil through cooling channels inside the mold. Although not as efficient as water cooling, this method works well for molds that need to be cooled at higher temperatures which are used with high-temperature injection molding.

3. Electric Heating System: Instead of using heating elements to heat the mold and regulating its temperature, an electric heating system controls the mold’s temperature by creating flows of electricity. When very specific temperature control is crucialm for example, with hot runner molds, these systems can be paired up with cooling ones as well.

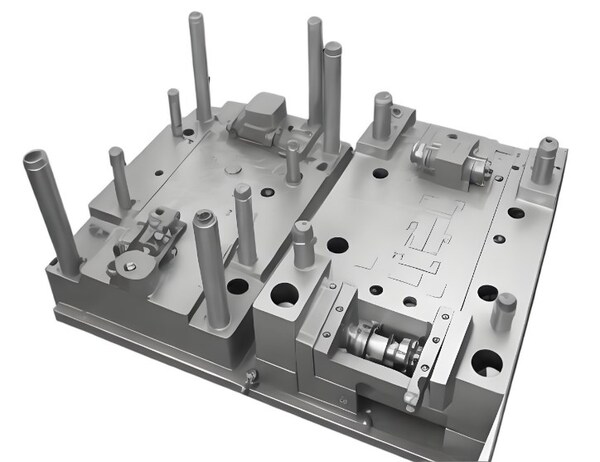

The Impact of Runner Design on Injection Speed

Runner Types

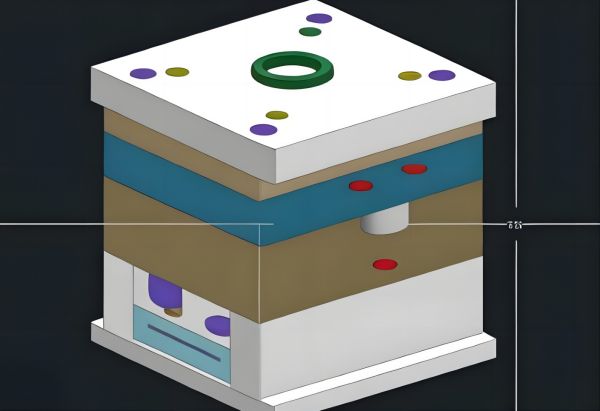

Runner system is a way through which molten plastic is transported to the mold cavity from the nozzle of an injection molding machine. Indeed, the layout of flow lines has an impact on injection speed of subsequent layers and, therefore, the quality of the final product. Some of the runner types commonly used comprise of the cold runners and the hot runners.

1. Cold Runner: Cold runners are conventional runner systems in which the solidification of the molten plastic takes place in the runner generating scrap. Cold runners are easy to design and economical on material and energy but make excessive use of the latter and slow down the injection rate as well as economy.

2. Hot Runner: Hot runners employ heating element that maintains the plastic in a molten state in the runner so that waste is not encouraged. Hot runners can enhance injection speed, decrease the using rate and the manufacturing costs, but they are more costly in design and manufacturing, thus ideal for voluminous production.

Runner Layout

The orientation of the runner layout has a direct relation to the type of injection speed. The correct positioning of runners also leads to insignificant flow resistance and, therefore, faster and smoother filling. In regard runner arrangement, balanced and unbalanced runners are typical.

1. Balanced Runner: Equal channel layouts help to have opposite flow routes and pressure for the molten plastic to enter the cavity and allow the flood of every cavity at the same time meaning higher injection rate and uniformity of the product.

2. Unbalanced Runner: The unbalance runner arrangements make different flow paths and resistance of the entering molten plastic for each cavity; hence, causes unequal cavity fill-up or injection speed and affects the product quality. It is applied in particularized injection procedures including differential injection and has an uneven distribution of the increments.

The Impact of Mold Maintenance on Injection Speed

Mold Maintenance

Proper mold care is important to keep the injection speed and also the quality of the product on the right level. Daily mold maintenance can help in increasing the life span of the mold, decrease the failure rate and improve productivity.

1. Regular Cleaning: To reduce time for the injection and improve the quality, remove the accumulated residues, impurities and rust on the mold surfaces , cavities, runners and any other area if possible keep the mold clean an smooth.

2. Regular Lubrication: Generally, greasing of moving parts of the mold for instance; guide pin, bushing, and ejector pin play a vital role in reducing the friction and wear hence enabling smooth running of the mold, enhancement of the injection speed and moreover elongation of the mold’s life span.

3. Regular Inspection: Check all mold components for example cavities, cooling systems, venting systems should check frequently so that you can repair or replace damaged or worn component before they interferes with the injection speed and quality of the end product.

Mold Maintenance

Mold maintenance stabilises mould for the long term. A correct mold design will help in improvement of the mold’s durability and increased shots per minute.

1. Storage Environment: Molds need to be properly stored to stop them from getting wet, rusty and contaminated they should be stored in a clean, well aerated and free from dust environment. Molds should be cleaned and then wiped and or painted with anti-rust oil before being put away for storage.

2. Maintenance Records: Record: Store each maintenance, repair, and inspection’s time, content, and result to monitor mold use and maintenance efficiency.

3. Regular Maintenance: Have a routine calendar on times of mold usage, and general mold requirements for checks, washing, greasing, and repair on a set agenda to make sure that the molds are always fit for use.

The Impact of Innovative Mold Technologies on Injection Speed

With technological advancements, innovative technologies are increasingly being incorporated into mold design and manufacturing to improve injection speed and production efficiency. Here are some common innovative technologies:

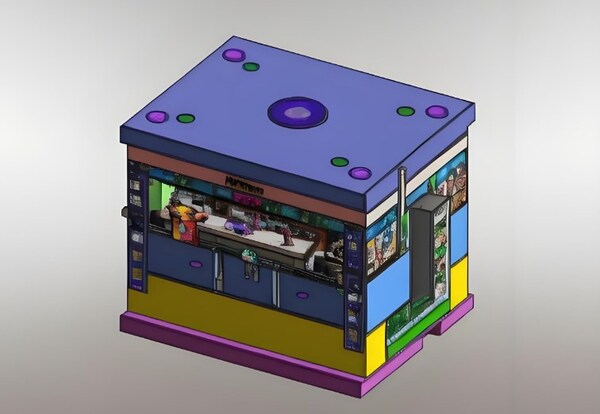

Digital Design and Simulation

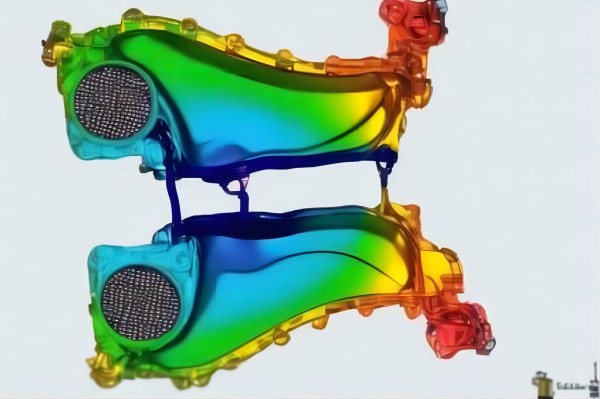

Improved tools of digital designing and simulation enhance the operation involved in mold design and optimization. Some of them are computer aided design (CAD), computer aided manufacturing and computer aided engineering (CAE) which includes, finite element analysis (FEA).

1. Computer-Aided Design (CAD): By using CAD software in designing the mold it is made easier and designs can be easily changed thus making the work competent. By visualizing, it’ll be easier for designers to observe and modify a mold structure with actual molding designs, required improving the speed of injection.

2. Computer-Aided Manufacturing (CAM): CAM software translates the CAD models into actual paths to be machined in actual control of the CNC machines for accurate cutting. CAM technology reduces accuracy in machining, reduces manufacturing time as well as enhances the rate of injection.

3. Finite Element Analysis (FEA): During injection process, FEA technology carry out stress, deformation and temperature distribution test aimed at predicting mold’s performance by the designers. With regards to design parameter, FEA can help to determine optimum structure and material of the mold, molding defects, as well as injection speed.

Additive Manufacturing Technology

AM technology or 3D printing constructs components by accretion, in which layers are built up. It is widely used in mold manufacturing, which is commonly used for mold prototype and mold repair.

1. Mold Prototype Manufacturing: First, AM technology quickly creates molds for the validation of the designs and for making a relatively small number of works. Through AM, there is fast processing of the material together with negligible wastage, which effectively reduces the time to develop many molds and improves the speed of injection.

2. Mold Repair: This is a 3D mold repairing and remanufacture technology in additive manufacturing technology. If the mold parts are worn or damaged, the additive manufacturing can do localized build-up to help lengthen the span of the mold and improve productivity.

Hot Runner Systems

Hot runner systems keep the plastic in molten state in the runner heating it, therefore no waste of material and cavity pressure drops as witnessed in cold runners. Thus, accurate implementation of the hot runner system injection rates and the quality of the final product may be improved considerably.

1. Hot Runner Design: To get maximum thermal stability in the runner system, hot runner design should be appropriate to facilitate good temperature distribution throughout the various systems that enhance the filling speed and the quality. Valve gates and hot sprues are the most familiar hot runner designs.

2. Temperature Control: Hot runner systems need temperature control hence ensuring that the plastic is in a correct state to flow through the injection process. Superior temperature control might enhance the injection rate and the quality of products.

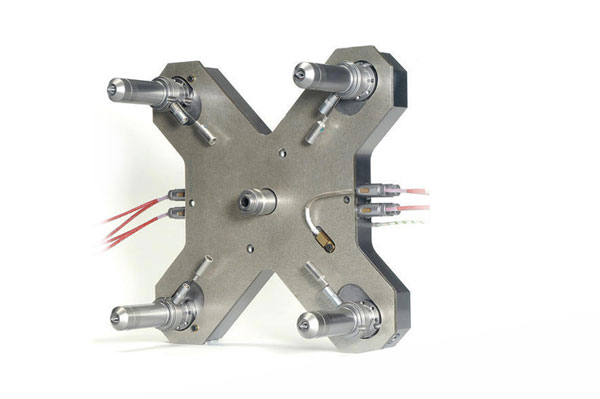

Composite Mold Technology

The composite mold technology in plastic production involves using the composite material and structure in the mold to improve the operation efficiency of the mold and the injecting speed. Some of the technologies include; Insert molding, Two shot molding and the Sandwich molding.

1. Insert Molds: Embedded molds enhance the mold performance while at the same time raising the injection rate and are mold inserts that are made of various materials. For example, high-hardness material may be set up in high-wear region; high-thermal-conductivity material may be set up in high-heat region.

2. Two-Shot Molds: The two-shot molds can produce products that have two colours or two different materials in the process of injection that is faster and creates better products. However, two-shot molds are design and manufactured in a more complicated way, but they certainly help to increase injection speed.

3. Sandwich Molds: It also said sandwich molds are effective in increasing the thermal conductivity and cooling through accommodation of layers in the mold. The fact is that the use of sandwich molds directly affects reductions in cooling time as well as an increase in injection speed.

Conclusion

The injection mold is the most important aspect of injection molding and the design of the mold, the material of the mold, manufacturing, and the control of the heat, the design of the runners, and maintenance are some of the factors that will affect the injection speed. It is rational to optimize the mold by increasing the injection speed under the premise of applying new technologies, which can significantly improve production efficiency and product quality.

In the future, with the development of digital design simulation technology, new generation of manufacturing equipments such as additive manufacturing technology, hot runner system and composite mold technology, injection mold will play more large role in manufacturing industry, giving strong support for various industries. As for the injection molding technology and mold design, more innovation and development will be achieved in the future through continuous research and practice, bringing new changes to the manufacturing industry.