Injection molds are crafted through a detailed, multi-step process that transforms raw materials into durable, precise tools essential for producing plastic parts across industries.

Injection molds are made by combining machining techniques like CNC milling, EDM, and grinding to shape metal blocks, typically steel or aluminum, into the desired mold structure. This process includes several stages: designing, machining, and finishing. Key factors include mold material, precision requirements, and intended production volume, all tailored to ensure efficient, high-quality part production.

While this summary outlines the basics of injection mold manufacturing, an in-depth understanding of each step can help optimize mold design for specific applications. Explore further to learn how variations in mold-making processes impact final part quality and production efficiency.

Injection molds require precise machining to ensure part quality.True

High precision in mold manufacturing ensures consistent, defect-free parts in injection molding applications.

All injection molds are made from steel.False

While steel is commonly used for high-volume production molds, aluminum molds are also used for low to medium production due to cost-efficiency and faster machining times.

How to Accept Customer Customization Requirements?

Understanding how to navigate customer customization requests is crucial for any business aiming for growth. By implementing effective strategies, you can enhance customer experience and streamline your operations. Dive deeper to learn how to optimize your customization process and strengthen customer relationships.

The production of plastic molds starts when the customer’s engineering personnel provide product drawings or physical objects to the mold manufacturer.

The manufacturer needs to understand the purpose, processability, dimensional accuracy, and other technical requirements of plastic parts. Collecting, analyzing, and digesting product data is the process of accepting customer customization needs through the task requirements of molding plastic production.

What are the Key Elements to Consider When Creating a Mold Design?

Key elements to consider in mold design include material selection, cooling system design, parting line placement, and gate location. Properly addressing these factors ensures optimal flow, minimizes defects, and enhances manufacturability. A well-designed mold can significantly reduce cycle times and production costs while improving product consistency.

Analysis and Digestion of 2D and 3D Drawings of Products

I look at 2D and 3D drawings of products. I look at the shape of the product, how big it is, how close to the size it has to be, what it’s supposed to look like, what it’s supposed to do, what kind of plastic it’s made out of, how much it shrinks, what color and desired shape it is, what it’s supposed to feel like.

Determine the Injection Type

When you choose an plastic injection molding machine, you need to consider the plasticizing rate, mold cavity1 injection volume, clamping force, effective area for installing the mold, ejection method, and fixed distance. That’s why some customers send the information of the injection molding machine together for your reference when sending RFQ.

Determine and Arrange the Number of Mold Cavities

Most of the time, the customer will tell you how many cavities they want, but sometimes you have to decide for yourself.

It’s mainly based on the product’s production batch (monthly or yearly), the size of the mold and the effective area of the injection mold for installing the injection (or the internal spacing of the injection machine tie rod), the weight of the product and the injection volume of the injection machine, the projected area of the product and the clamping force, the accuracy of the product, the color of the product, and the economic benefits (the production value of each mold).

Determine the Parting Surface

In general, the parting surface on the plane is easier to handle, and sometimes you should pay special attention to the parting surface in the three-dimensional form2.

Determination of the Mold Base and Selection of Standard Parts

Most of the time, customers will ask us which materials to use. But sometimes when we choose it ourselves, it is important to check the necessary strength and rigidity of the mold-related parts to check whether the selected mold frame is suitable, especially for large molds.

Design of the Pouring System

a. Try to keep the distance between the gate3 and all parts of the mold as consistent as possible, and make the flow path as short as possible (although it is difficult to do with a large gate).

b. The gate should be placed so that when the molten plastic is injected into the cavity, it faces the part of the cavity that is spacious and has a thick wall, so that the plastic can flow easily.

c. When the plastic flows into the cavity, try to avoid it rushing directly to the cavity wall, core, or insert, so that the plastic can flow into all parts of the cavity as quickly as possible and avoid deforming the core or insert.

d. The gate should be designed at the easiest part to remove on the product, while minimizing the impact on the appearance of the product.

Design of Ejection System

The product can be ejected in three ways: mechanically, hydraulically, or pneumatically.

Design of Cooling System

a. Organizing the cooling system and choosing the type of cooling system.

b. Deciding where and how big the cooling system should be.

c. Cooling important parts like the core or insert of the moving mold.

d. Cooling the side slides and side slide cores.

e. Designing the cooling components and picking standard cooling components.

f. Designing the sealing structure.

Selection of Mold Steel

The choice of materials for mold forming parts (cavity, core) is mainly determined by the batch and plastic category of the product.

Confirmation of Mold Drawing

Once the mold design drawing is done, it must be sent to the customer for approval. Only after the customer agrees can the mold be put into mass production. When the customer has a big opinion and needs major changes, it must be redesigned and then handed over to the customer for approval until the customer is satisfied.

Exhaust System

There are a few ways to vent:

a. Use vent grooves. Vent grooves are usually placed where the cavity is last filled. The depth of the vent groove varies with different plastics, and is basically determined by the maximum clearance allowed when the plastic does not produce flash.

b. Use the matching clearance of the core, insert, push rod, etc. or a special vent plug to vent.

c. Sometimes, in order to prevent vacuum deformation caused by the workpiece, it is necessary to design a vent pin.

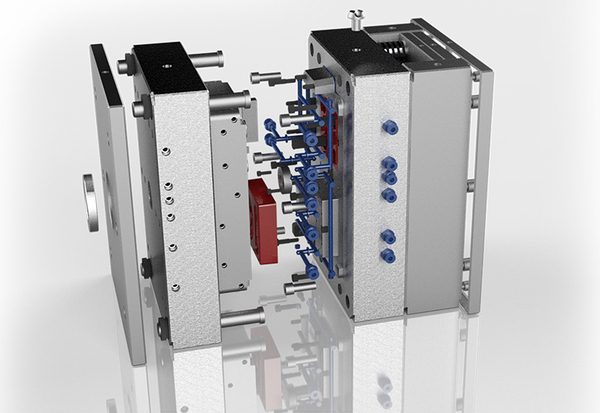

The engineering team designs the mold structure4 according to the product drawings, arranges and draws drawings.

How to Make Plastic Injection Mold?

To make plastic injection molds, begin by designing the mold using CAD software, followed by selecting the right materials, typically steel or aluminum. The mold is then machined and assembled to fit injection molding machines. Key steps include prototyping, testing, and optimizing the mold for specific production needs.

Programming and Removing Electrodes

Once the mold design is done, you need to make CNC programs and take out the electrodes for EDM processing based on the processing conditions of each part.

Machining

The mold is mechanically processed, including CNC processing, EDM processing, wire cutting processing, deep hole drilling processing, etc.

After the mold base and materials are ordered, the mold is only in a rough processing state or only steel material. At this time, a series of mechanical processing must be carried out according to the design intention of the mold to make various parts.

CNC processing5, computer numerical control, is also a numerical control machining center, and its requirements include various processing procedures, tool selection, processing parameters, etc.

EDM processing is electrical discharge machining, which is a process that uses discharge to corrode materials to reach the required size, so it can only process conductive materials. The electrodes used are generally copper and graphite.

Bench Assembly

Bench work is very important in the mold making process, and it runs through the entire mold manufacturing process. Bench work, fit mold assembly, turning, milling, grinding and drilling are all good.

Mold Saving and Polishing

Mold saving and polishing is the process of using sandpaper, oilstone, diamond paste and other tools to process the mold parts after the mold is processed by CNC, EDM, and bench work, and before the mold is assembled.

What is Mold Inspection and Mold Trial?

Mold inspection involves examining molds for defects and quality issues before production begins. A mold trial tests the mold to verify its performance, ensuring that parts meet specifications. Key benefits include identifying potential problems early and optimizing production efficiency, ultimately leading to higher quality products.

Mold Inspection

The plastic mold acceptance standard is a series of steps to inspect, test, and evaluate the mold after it is made to make sure it meets the design requirements and manufacturing standards. The following are the main contents of the plastic mold acceptance standard:

Plastic Mold Appearance Inspection

Check if the surface of the plastic mold is flat, without cracks, burrs, bubbles, and other defects, and if there is any obvious deformation or damage.

Plastic Mold Size Inspection

Check if the size of the plastic mold meets the design requirements, including the overall size of the mold, the size of the parts, the size of the hole, etc.

Plastic Mold Steel Material Inspection

Make sure the materials used for the plastic mold meet the design requirements and manufacturing standards, including mold steel material, hardness, heat treatment, etc.

Plastic Mold Assembly Inspection

Make sure the plastic mold is put together right, the parts are tightened, the bayonet is tight, and the guide pins, guide bushings, springs, and other stuff are all there.

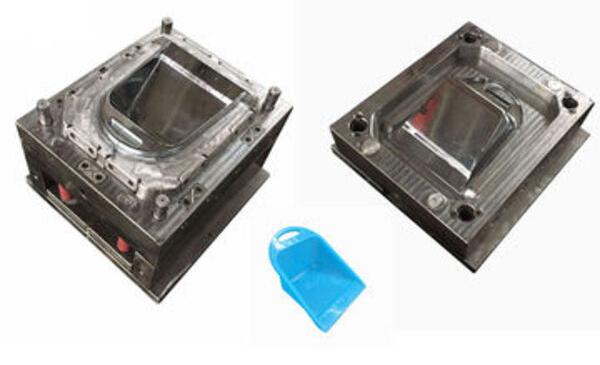

Plastic Mold Trial

Do a plastic mold trial to see if the mold opens and closes right, if it ejects right, if it cools right, if the plastic flows right, and if it makes parts that are good.

Plastic Mold Life Test

Conduct mold life test to check the use of plastic mold within a certain injection molding cycle, including the wear, deformation, cracks, etc. of the plastic mold.

Maintenance Instructions for Plastic Molds

Learn how to maintain plastic molds, including cleaning, lubricating, and preventing rust on plastic molds to make them last longer.

Mold Trial

a. First, get to know the mold trial process and key precautions during the mold trial process by understanding the following materials.

b. Get to know the actual mold trial process by practicing at the mold trial site.

c. Check the mold appearance, mold material, pouring system, mold support. Reset. Extraction and insertion of cores. Pick-up, exhaust. Water transportation system, injection molding process system, product appearance, size, and functional coordination for acceptance.

After the mold is made, before the first mold trial

Check if the mold has safety devices (like if there is a forced return mechanism, or an ejector plate limit switch mechanism, these mechanisms are devices that make sure the mold won’t be damaged in an abnormal state).

Check if the mold ejection and return mechanisms are installed

Common ejection and return mechanisms include tie rod mechanisms (whether the tie rods are balanced and whether the number of tie rods is sufficient must be confirmed) and cylinder mechanisms.

Sometimes there will be gas-assisted ejection assistance. Whether the nozzle needle is made into a Z shape to pull the cold material position (it is found that the nozzle often sticks to the mold in the sixth workshop). The end face of the return rod is flat and there is no spot welding. There is no gasket at the bottom of the embryo head, spot welding.

All slider molds should have oil grooves on the moving part of the slider.

After the mold is installed on the injection molding machine, don\’t rush to do injection molding and mold adjustment. Instead, ask the technician to set the injection molding machine to manual operation gear and ask the technician to manually do each action of the mold.

After the above preliminary work is confirmed, the mold can be adjusted.

Also, in addition to the size, appearance, and other defects of the sample itself, it is also necessary to combine an overall assembly confirmation. Therefore, every time you try the mold, you must try to bring all the assembly parts.

The overall assembly confirmation can give you a more direct understanding of the assembly problems of the trial mold product. In addition, for the existing assembly problems, it is more convenient to analyze the modification plan. It can avoid complexity and save time.

Once the mold is made, we need to use the injection molding machine to make a trial mold to see if the mold is good and if the plastic part structure is good. Through the trial mold, we can see the mold in the process of making beer and see if the plastic part structure is good.

How to Carry out Mold Modification and Mold Repair?

Mold modification involves adjusting the mold design to improve part quality and reduce defects, while mold repair focuses on fixing damages to extend the mold’s lifespan. Key techniques include surface polishing, replacing damaged components, and making design alterations to enhance functionality.

When you use a plastic mold for a long time, it will inevitably wear out. When the mold is damaged or deformed, we need to repair it in time to ensure that the products produced by the injection molding machine are not defective.

Methods of Mold Modification for Injection Molding

Redesign the Mold

The key to completely solving the problem is to redesign the mold. Based on the problems of the original mold, the mold structure, parting surface, gate position, etc. are optimized and designed.

At the same time, the selection of mold materials and the optimization of heat treatment process need to be considered to improve the life and durability of the mold. For example, in order to solve the problem of insufficient melt filling caused by uneven parting surface of the mold, the parting surface can be redesigned to make the melt filling more uniform.

Modify Mold Parameters

Changing the mold parameters is a simple and quick way to modify the mold. By adjusting the parameters such as the size of the mold, the precision of the mold, and the surface roughness of the mold, the quality and production efficiency of the product can be improved.

For example, by adjusting the size and position of the gate, the filling process of the melt can be optimized and the quality of the product can be improved; by reducing the surface roughness of the mold, the residue of the product can be reduced and the production efficiency can be improved.

Replacement of Mold Accessories

Swapping out mold accessories is a popular and relatively cheap way to modify molds. For parts in the mold that are prone to wear and failure, like cavities, cores, gate sleeves, etc., you can choose to replace them with materials or surface treatments that are more resistant to wear and corrosion.

You can also choose more advanced mold components based on your actual production needs to improve production efficiency and product quality. For example, replacing a cavity that wears out easily with a highly wear-resistant material can effectively extend the life of the mold.

Modifying injection molds is a big deal. It’s a big deal because it can make your parts better and your production faster. When you’re modifying a mold, you need to know what you’re doing.

You need to know what you’re doing because you don’t want to screw it up. You don’t want to screw it up because you don’t want to make a bad mold. You don’t want to make a bad mold because you don’t want to make bad parts.

You don’t want to make bad parts because you don’t want to lose money. You don’t want to lose money because you want to make money. You want to make money because you’re in business. You’re in business because you want to make money.

Processing of Cooling System:

Cooling system processing (drilling and water transportation), the product generally requires that the front mold water transportation needs to be processed when the first mold modification data is issued, and the rear mold water transportation needs to be processed after the second mold modification data is issued.

However, for situations where the opening of water transportation has a greater impact on the brewing, such as the brewing of PC materials (hot oil brewing is required), try to open it before the first trial mold.

Processing of Cooling System

So, when you’re doing the structural design drawings, you need to think about all the different situations, and try to reduce the amount of work you have to do to change the mold, so that the water can flow through the pipe, and you can figure out how big the beer is going to be as soon as possible.

Why do We Need Mold Maintenance?

Mold maintenance prevents defects and extends the life of molds by keeping them clean and functioning properly. Regular checks help identify wear and tear, reducing production interruptions and costs. Key benefits include improved part quality, decreased scrap rates, and enhanced production efficiency.

In the daily production process, mold maintenance is more important than mold repair. This is because mold repair is similar to repairing mechanical equipment. The more times the mold is repaired, the worse its performance becomes. To a certain extent, it also reduces the lifespan of the mold.

Because the mold works under high temperature and high pressure, and is in contact with air for a long time, it is very easy to rust, so the mold needs to be well maintained. When it is not brewing, it needs to be coated with anti-rust oil and butter, etc., and the use time of the mold will be extended accordingly.

Also, because the mold steel6has a service life and the mold structure design is not reasonable, some thin steel structures or ejector pins may crack and break, and they need to be constantly maintained and repaired in the later maintenance. Therefore, we must do a good job of mold maintenance in normal times.

Conclusion

Zetar Mold Co., Ltd. is a one-stop service manufacturer from mold design, injection mold processing, product injection molding, plastic shell surface treatment (spraying, silk screen, etc.).

The company is well-equipped and has a group of technicians with 20 years of experience in injection mold processing. We, Zetar Mold, are a company run by love. Our purpose is to create a happy enterprise. We focus on solving various customization problems for customers.

-

Learn about Mould Cavity: Casting is the process where raw material gets melted, heated to the desired temperature. ↩

-

Learn about Automatic Determination of 3-D Parting Lines and Surfaces in Plastic Injection Mould Design: The 3-D parting lines are generated based on the proposed criterion of considering the above projected areas of edge-loops. ↩

-

Learn about Types Of Gates For Injection Molding: A Complete Design Guide: An injection molding gate design helps companies to manufacture plastic components with the best quality. ↩

-

Learn about Injection Mold Components: Understanding The Structure: The main components of an injection mold system include the mold base structure, the molding system, the feed system, the ejection system…. ↩

-

Learn about What Is CNC Machining? An Overview of the CNC Machining Process: The CNC process runs in contrast to — and thereby supersedes — the limitations of manual control….. ↩

-

Learn about Mold Steel: Mold steel is a material that is used to manufacture the molds, including cold-punching mould, hot forging die, die-casting mold, and more. ↩