Injection molding is a popular and efficient manufacturing process used today. To improve production efficiency, lower costs, and improve product quality, hot runner systems are being used more and more in injection molds. This article will discuss when you should consider using a hot runner system and the benefits and potential problems you might encounter.

What is a Hot Runner System?

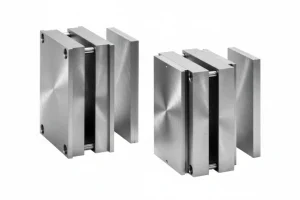

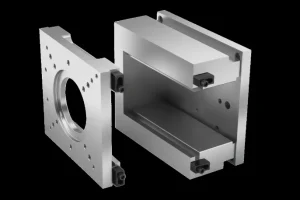

Hot runner systems are used in injection molds to keep the plastic melt at a consistent temperature in the runner so it doesn’t solidify during the injection process. This prevents material waste and quality issues that are common with traditional cold runner systems. A hot runner system usually has heaters, temperature controllers, nozzles, and manifolds.

The key to a hot runner system is precise temperature control, which ensures that the plastic melt flows evenly into the mold cavities to create the desired product shape. Compared to cold runner systems, hot runner systems are much more efficient and give you better control over quality.

Advantages of Hot Runner Systems

Material Savings

In old-school cold runner systems, you have to recycle and reprocess the plastic that’s left over after it cools. Hot runner systems don’t have this waste, so you save a ton of money on materials. This is especially important for high-end engineering plastics because you’re not wasting material and you’re getting more out of it.

Increased Production Efficiency

Hot runner systems save time because you don’t have to wait for the cold runner to cool and solidify. This time savings can make you way more efficient, especially if you’re making a ton of stuff. If you can make stuff faster, you can make more stuff in the same amount of time.

Improved Product Quality

Hot runner systems make sure that the plastic melt stays at the same temperature and pressure all the way through the injection molding process, which makes the quality of the product more stable and even. This is especially important when you’re making parts that need to be super precise. Hot runner systems also help you avoid some of the common problems you get with cold runner systems, like air bubbles, inclusions, and cold weld lines.

Design Flexibility

Using hot runner systems allows for more freedom in mold design, as you don’t have to think about the layout of cold runners. This gives mold designers more flexibility to optimize product design. Hot runner systems can achieve complex mold structures, meeting different product requirements.

Reduced Maintenance Costs

While the initial investment in a hot runner system is high, the long-term maintenance costs are lower. With no cold runner waste, mold wear and damage are reduced, extending the mold’s service life. Hot runner systems reduce the frequency of disassembly and cleaning, lowering maintenance costs and downtime.

When Should a Hot Runner System Be Considered?

Hot runner systems have a lot of advantages, but they’re not right for every job. When you’re thinking about whether to use a hot runner system, several factors need to be taken into account.

Production Volume

The initial cost of hot runner systems is high, which can make them uneconomical for small-batch production. However, for mass production, hot runner systems can save a lot of material and increase production efficiency, which can offset the initial cost. So, if you’re going to make a lot of parts, you should think about using a hot runner system.

When you’re making a lot of parts, the material savings and faster cycle times can save you a lot of money. In these cases, the efficiency and stability of hot runner systems are important for staying competitive.

Product Complexity

Hot runner systems are great for making complex, precision-shaped products. They help make sure the material is spread out evenly and the temperature is just right, so the product comes out looking great. If you’re making something that’s really complicated and has to be just right, hot runner systems can make a big difference in how well things turn out.

When you’re making something that’s complicated, you have to be really careful about how you inject the plastic. Hot runner systems can help you avoid a lot of the problems you get with cold runner systems, like weld lines and gate marks. That means you get a smoother surface and a stronger part.

Material Type

Hot runner systems are good for most thermoplastics, but some special materials that degrade easily or are sensitive to temperature changes may need specially designed hot runner systems. So when you choose a hot runner system, you need to consider the characteristics and adaptability of the materials you are using.

Some special plastic materials are very sensitive to temperature changes. When you use a hot runner system, you need to control the temperature and pressure very precisely to avoid material degradation and performance degradation. This requires fine-tuning and optimization of the hot runner system.

Cycle Time

When you need to make a lot of parts quickly, hot runners can help you do it. If you want to make a lot of parts fast, you should use a hot runner.

Hot runners make each cycle go faster by cutting down on the time it takes to cool and heat the mold. This is important when you need to react quickly to what the market wants and be able to make a lot of different parts.

Environmental Requirements

In production environments with strict environmental requirements, it is essential to reduce waste and improve material utilization. Hot runner systems can significantly reduce plastic waste, helping you meet environmental requirements.

Environmental regulations and corporate sustainability goals require you to reduce waste and environmental pollution during production. Hot runner systems help you achieve your environmental goals by reducing waste and increasing production efficiency, which enhances your corporate image and social responsibility.

Economic Analysis

While the upfront cost of hot runner systems may be high, they can save you money in the long run by reducing material waste, increasing production speed, and lowering maintenance expenses. So, before you decide whether or not to buy one, you should do a detailed cost analysis that takes into account the upfront cost and the long-term savings.

To do a thorough cost analysis, you need to consider the upfront cost, the money you’ll save on materials, the increase in production speed, and the decrease in maintenance costs. By doing this kind of analysis, you can figure out if a hot runner system makes financial sense for your specific production situation.

Challenges of Hot Runner Systems

Despite the many advantages of hot runner systems, there are challenges and issues that need attention in practical applications.

High Initial Investment

Hot runner systems cost a lot to design and make, which can make it hard for small and medium-sized businesses to pay for them. So, before you decide to use a hot runner system, you need to make sure you have enough money.

The first thing you have to pay for is designing the system, buying the equipment, and getting it all set up and working. If you’re a small or medium-sized business, you have to plan and spend your money right to make sure you can get your hot runner system up and running.

Technical Complexity

Designing and maintaining hot runner systems requires a lot of technical know-how. If you don’t know what you’re doing or you don’t take care of your system, you’re going to have problems. Those problems can slow down your production and mess up your parts. So, you need to know what you’re doing or you need to hire someone who does.

The technical stuff comes into play when you’re designing the system, when you’re installing it, when you’re getting it up and running, and when you’re taking care of it every day. You need to know what you’re doing to keep it running right and to get the most out of it.

Temperature Control

Temperature control is very important for hot runner systems. If the temperature is too high or too low, it will affect the flow of plastic and the quality of the product. Therefore, we need to use high-precision temperature control equipment and train operators professionally.

The key to the success of hot runner systems is precise temperature control. We need to configure high-precision temperature control equipment and operators must be proficient in the operation and maintenance of this equipment to avoid quality problems caused by temperature fluctuations.

Maintenance and Upkeep

Hot runner systems need regular maintenance and upkeep to keep them running smoothly. This includes cleaning the heaters, checking the nozzles, and replacing any worn parts. If you don’t keep up with maintenance, you could have system failures and downtime.

Regular maintenance and upkeep can not only make your system last longer, but it can also help you make better products faster. You should have a good maintenance and upkeep system in place to keep your system running smoothly.

Material Selection

Not all materials are suitable for use with hot runner systems. Some special materials may require specially designed hot runner systems. Therefore, it is necessary to understand the characteristics of the materials used in detail and choose a suitable system.

Different plastic materials have different flow properties, thermal stability, and processing characteristics. Selecting a suitable hot runner system requires detailed analysis of material properties to ensure the system design can meet material requirements.

Case Studies

To better understand the application of hot runner systems, let’s look at a few real-world cases.

Case 1: Automotive Parts Production

A car parts maker uses a hot runner system to make fancy plastic parts. The old cold runner system couldn’t make the parts because they were too fancy and needed to be perfect. The hot runner system made the parts better, faster, and with less waste.

In this case, the hot runner system made the plastic go where it was supposed to go and made the parts come out the same every time. The car parts maker made the parts faster and better with the hot runner system.

Case 2: Household Appliance Housing Production

A household appliance manufacturer uses a hot runner system to produce large batches of plastic housings. Due to the large size of the housing products, using a traditional cold runner system would generate a lot of cold runner waste, increasing material costs. The hot runner system not only reduced waste but also shortened the production cycle and increased overall production efficiency.

In this large-scale production scenario, the hot runner system helped the appliance manufacturer significantly reduce production costs and improve market competitiveness by reducing waste and increasing production efficiency.

Case 3: Medical Device Production

When you’re making medical devices, precision and quality are everything. That’s why a medical device manufacturer uses a hot runner system to make high-precision plastic parts. It’s all about making sure the products are consistent and reliable. The hot runner system was expensive to buy, but it paid off in the long run because it saved money and improved quality.

When you’re making medical devices, you have to be super careful. That’s why a medical device manufacturer uses a hot runner system to make high-precision plastic parts. It’s all about making sure the products are consistent and reliable. The hot runner system was expensive to buy, but it paid off in the long run because it saved money and improved quality.

Conclusion

Using hot runner systems in injection molds can make production faster, save on materials, and make better products. But you have to think about whether you should use a hot runner system. You have to think about how many products you’re making, how complicated they are, what kind of plastic you’re using, how fast you want to make them, what kind of environment they’ll be in, and how much money you have. Even though hot runner systems cost a lot of money at first, they save you money in the long run and make better products.

When you use hot runner systems, you have to know how to use them and train your workers to use them. If you use hot runner systems right, you can make products faster and cheaper, and you can beat your competition.