Injection mold costs can vary a lot. The size and complexity of the parts, the type of plastic, and the quantity of parts all play a role. Bigger parts with more complex shapes need more expensive molds and take longer to make, which drives up the cost per part. The type of plastic also affects the cost of injection molded parts. Some plastics cost more than others. The quantity of parts you make also affects the cost per part. The more parts you make, the cheaper each part is. The biggest upfront cost is building the mold. That can cost anywhere from a couple thousand to tens of thousands of dollars, depending on how big and complex the mold is. But once you have the mold, parts can cost anywhere from a few cents to tens of dollars, depending on how big and complex the part is.

Precision injection molds are important equipment for producing plastic injection molded products. When the design requirements for precision injection molding molds are high and manufacturing difficulties are significant, factors such as the need for multiple sets of molds to process complex injection molded parts contribute to the often high prices of precision injection molds.

This article will take you through the specific reasons for the high cost of injection molds, understanding the components of mold costs and the factors influencing design, to assist businesses in making informed material and design choices, effectively reducing mold costs, and improving production efficiency and quality.

Ⅰ. What is Injection Mold Making?

Injection molds are tools that are used to make a lot of plastic stuff in factories. They decide how the plastic stuff looks and how big it is. Injection molding is a way to make a lot of plastic stuff at once. It means melting plastic and putting it into a mold. The plastic cools down and becomes the shape of the mold. Injection molding can make plastic stuff that is very complicated. It is a good way to make a lot of plastic stuff. The quality of the plastic stuff depends on the mold. To make a good mold, you need to use a computer to design it and use a computer to make it. You also need to know how to make it. This is a good way to make a good mold and make a lot of plastic stuff.

Ⅱ. Why Are Injection Molds Expensive?

1. High Costs

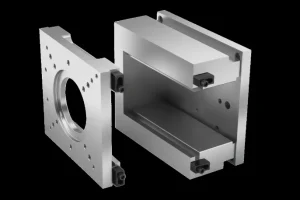

Injection mold production usually requires high-quality, high-cost materials, as well as advanced technology and equipment. Common mold materials include steel, alloys, and aluminum, and the production process involves multiple operations and several machining steps to complete. These steps include design, machining, electrical discharge machining (EDM), polishing, and assembly, resulting in naturally high production costs.

2. High Complexity

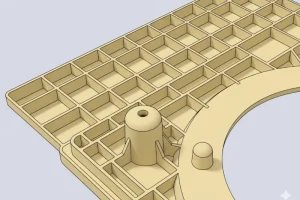

The price of injection molds is also influenced by the complexity of the manufacturing process. The complexity of plastic molds directly affects the production speed and cost. Typically, molds with more intricate features such as undercuts, curved surfaces, and hollow sections are considered more complex and incur higher production costs. Additionally, larger molds require larger mold-making equipment and processing facilities, which further increases mold costs.

3. Mold Lifespan

Mold prices are also influenced by specifications and lifespan. Some large-scale manufacturers require the production of large quantities of products, necessitating the use of high-quality molds to ensure the durability and reliability of continuous production. Different mold lifespans and specifications affect mold prices. Low-end molds, such as those used for short-term small-batch production, are relatively inexpensive. However, if a high-end mold is required for long-term use, its price may be significantly higher.

4. Time Costs

Injection mold manufacturing takes a long time. To get it right, many plastic mold manufacturers watch the mold-making process like a hawk, spending extra time and money to make sure the customer is happy. That means more time and more money.

5. Process Costs

Injection mold manufacturing involves multiple processes, high costs for purchasing standard components, and a relatively large workforce for complex operations. To ensure quality in complex processes, plastic mold manufacturers often need to conduct numerous tests.

Injection molding mold manufacturing is a difficult process, and the design requirements for injection molded part molds are high, especially the design of the mold flow channel, such as the initial mold flow analysis. If the design work is not done well or does not meet the requirements, if the trial molding fails, it is very difficult to modify the mold, and in most cases, it is necessary to make a new mold.

6. Mold Quantity

The number of mold sets you need depends on your samples. Sometimes, even simple plastic parts need two or three sets of injection molds to finish processing.

Ⅲ. Components of Injection Mold Costs

The main things that make up the cost of an injection mold are the cost of the material, the cost of designing and making the mold, the cost of running the mold, and the cost of fixing and maintaining the mold.

1. Raw Material Costs

The main cost of mold making is raw materials, including steel, electrodes, heat treatment, hardening, grinding, plastics, etc. The quantity and price differences of different materials have a significant impact on costs.

2. Design and Manufacturing Costs

The cost is also determined by the complexity of the mold design and manufacturing. Developing new molds requires a focus on the design process, optimizing structures, and minimizing material usage. Advanced machining equipment and technology can increase efficiency and accuracy, thus reducing costs.

3. Overhead Costs

Overhead costs are things like labor, energy, and rent. For example, if you hire a lot of designers, technicians, and managers, your fixed costs go up. Similarly, if you use equipment that uses a lot of energy and processes that aren’t efficient, your energy costs go up.

4. Maintenance and Repair Costs

As molds are used more, they may get damaged, which means you have to spend more money to fix or replace them. But if you take care of your molds, you can prevent damage and make them last longer, which will save you money.

5. Lifespan and Durability

How long a mold lasts and how well it holds up are two of the most important factors in determining the price of a mold. The design and quality of a mold are the two biggest factors in how long it lasts. Better molds last longer, but they also cost more.

6. Complexity and Size

The price of molds is also affected by complexity and size. If the mold design and manufacturing are complex, it will take more time and resources, which will increase the cost. The size of the mold also affects the amount of material needed and the difficulty of processing, which will affect the cost.

7. Quantity and Batch

The number and size of the molds you need will also affect the cost. In general, molds for large production runs cost less per unit because the fixed costs are spread out over more units. Molds for small production runs cost more per unit because you can’t spread the fixed costs out over as many units.

Ⅳ. Factors Influencing Injection Mold Design

1. Material Type

Mold materials are mainly divided into cold (hot) work molds and hard alloy steels. Different materials have different design and processing difficulties, but generally, cold (hot) work molds require more materials.

2. Number and Complexity of Parts

The complexity and number of parts in injection molds affect the design difficulty, workload, and manufacturing costs. Developing molds with medium or high complexity requires a high-level design team and more manpower and funding.

3. Product Size Requirements

The size of the injection mold affects the complexity of the design and the cost of manufacturing. If the product is small and requires high precision, the machining accuracy of the mold needs to be high, which will increase the cost of materials and equipment.

Ⅴ. Injection Mold Manufacturing Process

1. Production Technical Preparation

Technical preparation for production is the foundation of the entire production process, which has a significant impact on the quality, cost, progress, and management of the mold. The tasks in this stage include mold pattern design, preparation of process technology documents, formulation of material and machining time quotas, and estimation of mold costs.

2. Material Preparation

The type, form, size, and relevant technical requirements of mold part blanks are determined by material preparation.

3. Injection Mold Part and Component Machining

Injection mold parts include the mold cavity, core, cavity fixed plate, and discharge plate. The cavity, core, and cavity fixed plate are the parts that do the work. The cavity fixed plate holds the cavity in place, and the discharge plate removes the parts and waste from the cavity.

4. Assembly and Debugging

The assembly and debugging team in the production department is responsible for assembling and debugging injection molds according to the production schedule.

5. Mold Trial Appraisal

Mold trial appraisal is to evaluate the rationality and correctness of injection mold design and manufacturing quality, ensuring that the mold meets expected functional requirements.

Ⅵ. How to Reduce Injection Mold Production Costs

1. Choose Suitable Mold Materials

When you’re picking out the materials for your mold, you need to think about a few things. First, you need to think about what your product needs to do and how many you’re going to make. You want to pick materials that are going to work well for your product, but you also want to pick materials that aren’t going to cost you a ton of money.

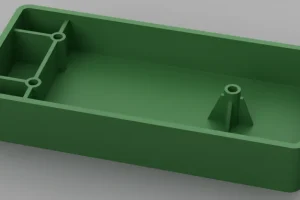

2. Optimize Mold Design

Smart mold design can improve production efficiency, reduce raw material waste, and lower production costs. When designing molds, you should consider the shape, size, structure, and production process of the product. The goal is to simplify the mold structure and reduce the number of mold parts.

3. Improve Mold Manufacturing Precision

Good mold manufacturing can improve product quality and precision, reduce the generation of defective products, and reduce production costs. By using high-precision processing equipment, improving the machining accuracy of mold parts, and strengthening adjustments and verifications during mold assembly, the rate of defective products can be effectively reduced, thereby lowering production costs.

4. Enhance Mold Reliability

To make molds last longer, you need to choose good quality mold parts and take good care of your molds. This will help you avoid having to fix or replace your molds as often, which will save you money.

5. Adopt Advanced Production Processes

By using advanced injection molding processes and technologies, like high-speed injection molding, multi-color injection molding, and precision injection molding, you can make your production more efficient and reduce your production costs.

6. Strengthen Supply Chain Management

Optimize the supply chain for raw materials, mold components, etc., to reduce procurement costs. Establish long-term cooperation with suppliers to negotiate better prices and services.

7. Improve Employee Skills

Improve employee training to boost technical skills and service awareness, which will help us work faster and save money.

8. Strengthen Product Quality Control

By implementing strict quality control, reducing the defect rate, and minimizing losses caused by quality issues such as rework and returns.

To reduce injection mold production costs, you need to optimize and break through in many aspects. Enterprises should take effective measures based on their actual situation to continuously improve product quality and production efficiency, so as to reduce production costs and enhance market competitiveness.

Ⅶ. Conclusion

The cost of injection molds is a big deal for manufacturing companies. If you know what goes into the cost of a mold and what affects the design, and if you make smart choices about materials and design, and if you take good care of your molds, you can cut your mold costs, make more parts, and make better parts. That saves you money and makes you more money.

Injection molds are the heart and soul of the injection molding process. They determine the quality, efficiency, and cost-effectiveness of production. Although the cost of making molds may seem high, it reflects the skill, precision, and technology that go into making them. It’s important for manufacturers and designers to understand what affects the cost of molds so they can optimize their production processes and find cost-effective solutions. By recognizing the value of good molds and investing wisely in their creation, manufacturers can unlock the full potential of injection molding as a versatile and efficient manufacturing method.