Foreword

Injection molding, also known as plastic injection molding, is a common method of manufacturing plastic product. As a mature plastic processing technology, injection molding materials, injection molding has broad development prospects. With the emergence of new technologies, new materials and new demands, injection molding will continue to adapt to market changes and innovative developments, providing higher quality plastic products for industrial manufacturing and consumers.

This chapter focuses on the six steps of the injection process: mold closing, filling, pressure holding, cooling, mold opening, and mold removal.

Mold Clamping Stage

The mold closing system should have reliable opening and closing mold actions, and a buffering effect when opening and closing the mold. The running speed of the movable platen should have a “slow-fast-slow” speed change requirement during mold closing and mold opening to prevent damage to the mold. and products, and avoid noise caused by strong vibration of the machine, so as to achieve safe operation and extend the service life of the machine and mold.

The maximum opening and closing stroke of the template determines the maximum thickness of the mold that can be installed in the injection molding machine, and therefore also determines the maximum thickness of the injection molded products that can be produced. Therefore, the template stroke should be adjustable.

The template must have sufficient strength and rigidity to ensure that it will not be deformed due to frequent various pressures during injection molding production, thereby affecting the size and shape accuracy of the injection molded products.

Basic Conditions for the Mold Closing Stage

Sufficient and adjustable clamping force to ensure that the mold will not be ejected under the action of mold cavity pressure.

The template of the fixed mold has sufficient area, stroke and opening distance, which can adapt to the molding molds of different shapes and sizes, and the opening distance can be adjusted freely.

The template movement speed is set in two levels: fast gear and slow gear. The fast gear requires smoothness, safety and controllability. The driving force of the clamping system comes from mechanical power or hydraulic force or a hydraulic-mechanical combination by a hydraulically operated connecting rod or toggle brace mechanism.

In order to smoothly demould and take out the parts, the mold closing system is designed with a product ejection device powered by pneumatic, hydraulic or mechanical power.

Technical Parameters of Mold Closing Stage

The technical parameters of the mold clamping system include the clamping force, the basic dimensions of the mold clamping device, the mold opening and closing speed and the empty cycle time. The clamping force is particularly important. It refers to the maximum clamping force that the mold clamping mechanism can exert on the mold. It should be greater than the average pressure of the melt in the mold cavity.

The thinner the wall of the product, the greater the injection pressure, and the greater the clamping force required to close the mold during injection molding. For example, the mold cavity pressure of ordinary packaging containers is generally around 25MPa, while thin-walled containers may require 30MPa. The actual set clamping force is determined by the product of the injection pressure and the projected area of the product.

Injection Stage

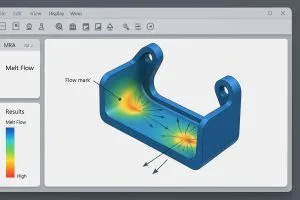

Injection is the first step in the regular casting process. When the mold is closed and casting begins, the mold cavity can be directly Injection up to 95%. In theory, the Injection time is much shorter and the molding efficiency is much higher. However, in actual production, there are many conditional limitations on molding time (or injection speed).

High-speed Injection: If the shear rate is high during high-speed Injection, shear thinning reduces the viscosity of the plastic and reduces the overall flow resistance. Due to the effect of local viscous heating, the thickness of the solidified layer also decreases.

Therefore, the Injection operation in the flow control stage generally depends on the size of the volume to be Injected. In other words, in the flow rate control stage, the shear thinning effect of the molten metal is often large due to high-speed Injection, but the cooling effect due to thin walls is not obvious, so the speed effect takes priority.

Slow Injection. When Injection is controlled by slow heat conduction, the shear rate is low, the local viscosity is high, and the flow resistance is large.The slow refill rate results in a relatively slow flow of hot plastic and poor material flow. Therefore, the heat conduction effect is more pronounced, and the heat is rapidly released through the cold wall of the mold. When combined with a lower amount of viscous heating, the solidified layer thickness increases further, further increasing the flow resistance in thin-walled sections.

The flow of the fountain aligns the plastic polymer chains in front of the flow wave approximately parallel to the flow wave front. Therefore, when two strands of molten plastic come into contact, the polymer chains at the contact surface are parallel to each other.Moreover, the two melts have different properties (different residence times in the mold cavity, melt temperature,different melting temperatures and pressures), which leads to a lower microscopic structural strength of the melt intersection region.

Place the piece under a light at a suitable angle and visually observe for obvious seams. This is the mechanism by which weld marks are created. Not only do weld marks affect the appearance of plastic parts, but the loose microstructure tends to create stress concentrations that can reduce the strength of the part and cause failure.

Generally, weld lines are stronger if they occur in high temperature areas. This is because at high temperatures the mobility of polymer chains is relatively good and they can penetrate each other and become entangled. Additionally, the temperatures of the two melts in the hot zone are relatively close and the thermal properties of the melts are almost the same, which increases the strength of the weld zone. On the other hand, welding strength decreases in low temperature ranges.

Holding Stage

The function of the pressure holding stage is to continuously apply pressure, compress the melt, increase the density of the plastic (densification), and compensate for the shrinkage behavior of the plastic. During the packaging process, the mold cavity is filled with plastic, creating high back pressure.

In the process of maintaining pressure and compressing, the screw of the injection molding machine can only advance slowly and lightly, and the flow rate of molten plastic flows is also relatively slow. The flow at this time is called the holding pressure flow. During the pressure holding stage, the plastic mold wall cools and solidifies faster, and the molten material increases rapidly, so the resistance inside the mold cavity becomes very large.

In the final stages of packaging, the density of the melted material continues to increase and plastic parts are gradually formed. The pressure maintenance phase continues until the door solidifies and seals. At this time, the pressure in the mold cavity reaches its maximum value during the conditioning phase.

During the holding phase, the pressure is so high that the plastic exhibits partially compressible properties. In areas of high pressure, plastic becomes increasingly dense. In areas of lower pressure, the plastic becomes looser and less dense, and the density distribution changes depending on location and time.

During the pressure holding process, the plastic flow is very low. As a result, the material flow is weak and cannot play a driving role. Pressure is the main factor affecting the process of maintaining pressure. During the pressure holding process, the plastic fills the mold cavity, and the gradually solidifying melt acts as a pressure transmission medium.

Appropriate clamping force is required when closing the mold, as the pressure inside the mold cavity is transmitted through the plastic to the mold walls, which tends to cause the mold to open.Under normal circumstances, the expansion force of the mold opens the mold slightly, making it easier to ventilate the mold. However, if the expansion force of the mold is too great, burrs and overflows may occur and the mold may open.

Therefore, when choosing an injection molding machine, you should choose an injection molding machine with sufficient clamping force to prevent mold expansion and effectively maintain pressure.

New environmental conditions for injection molding require the consideration of several new injection molding processes, including gas-assisted molding, water-assisted molding, and foam injection molding.

Cooling Phase

In injection molds, the design of the cooling system is very important. In fact, only after cooling and solidifying a plastic molded product to a certain degree of rigidity can it prevent deformation due to external forces after demolding.

Cooling time accounts for approximately 70-80% of the entire molding cycle. Therefore, a properly designed cooling system can significantly reduce molding time, improve injection molding productivity, and reduce costs.A poorly designed cooling system can extend molding time and increase costs. Uneven cooling will cause plastic products to deform more and become larger.

Experiments have shown that heat entering the mold from cast iron is usually lost in two parts, 5% of which is transferred to the atmosphere by radiation and convection, and the remaining 95% is carried from the cast iron to the mold. Heat the mold to mold temperature.

Due to the role of the plastic product cooling water pipe in the mold, the heat is transferred from the plastic in the mold cavity to the cooling water pipe by heat conduction through the mold frame and is discharged through the cooling liquid by thermal convection. The small amount of heat that is not removed by the cooling water continues to be transferred to the mold and is dissipated into the air after contact with the outside world.

The injection molding cycle includes mold closing time, filling time, holding time, cooling time and demolding time.

Cooldown time is the biggest part of this, around 70-80%. Therefore, the cooling time directly affects the molding cycle and yield of plastic products.

In the mold release process, the temperature of the plastic product must be cooled to a temperature lower than the heat distortion temperature of the plastic product in order to prevent the plastic product from deforming due to residual stress relaxation or deformation due to external force during mold release.

Mold Opening Stage

The process of opening an injection mold is generally divided into drawing mold drawings, proofreading and reviewing drawings, mold trial and repair, and organizing and archiving data.

Draw mold drawings: Before drawing the final assembly drawing of the injection mold, a process drawing should be drawn and must comply with the requirements of the part drawing and process data. The dimensions guaranteed by the next process should be marked with the words “process dimensions” on the drawing. If no other mechanical processing is performed after molding except for burr repair, then the process drawing will be exactly the same as the part drawing.

Proofreading and drawing review: Whether the plastic material, hardness, dimensional accuracy, structure, etc. of the injection mold and mold parts meet the requirements of the plastic part drawings.

Mold trial and mold repair: Mold design is carried out under expected process conditions when selecting molding materials and molding equipment, but people’s understanding is often incomplete; mold trial must be carried out after the injection mold processing is completed. Test and confirm the quality of castings. Once discovered, we will repair the mold to eliminate the error.

Organize and archive data: After the injection mold is tested, if it is not used temporarily, the demoulding residue, dust, oil, etc. should be completely wiped off, coated with butter or other anti-rust oil or anti-rust agent, and kept in a storage place.

The basic principle of injection molding: The injection molding machine takes advantage of the fact that plastic can melt into a liquid when heated to a certain temperature. The molten liquid is injected into a closed mold cavity with high pressure. After cooling and shaping, the mold is opened and ejected to obtain the required plastic. body products.

Demoulding Stage

Demolding is the last step in the injection molding cycle. Although the product is cold set and molded, demolding still has a huge impact on product quality. Using an improper demolding method may result in defects such as uneven force applied to the product during demolding or deformation of the product during ejection.

There are two main cutting methods. Demolding the ejector and demolding plate. When designing a mold, it is necessary to select an appropriate demolding method according to the structural characteristics of the product to ensure product quality.

For molds that use ejectors for mold release, place the ejectors as evenly as possible and choose locations that provide maximum resistance to mold release and maximum strength and rigidity of the plastic part to avoid distortion or damage. plastic part.

Release plates are commonly used to release thin-walled containers with deep cavities or clear products where push rod marks are not tolerated. This mechanism is characterized by large and uniform release force, smooth operation and no trace.

Conclusion

In other words, the injection molding process mainly includes six steps: mold closing – injection – pressure maintaining – cooling – mold opening – demoulding.These six steps directly determine the forming quality of the product, and these six steps constitute a completely continuous process that contributed to the formation of the modern world. Injection molding is a hallmark of innovation, driving advancements in manufacturing and opening up endless possibilities.

Plastic injection molded embodies the efficiency and precision of plastic part manufacturing. From mold design to ejection, every step is carefully executed to produce high-quality parts at scale. Its versatility and continued advancement across industries ensure its continued relevance and contribution to shaping the modern world. Injection molding is a testament to innovation, driving progress and unlocking endless possibilities in manufacturing.