Introduction

Injection molding is a manufacturing process used to mass-produce parts and products in large numbers. It involves injecting melted material, usually plastic, into an injection molding machine mold cavity to form the desired shape. Injection molding has become popular across numerous industries due to its efficiency, accuracy, and versatility.

Injection molding cost effective method for the mass production of parts, but the initial tooling costs can be quite high. As such, businesses must find ways to reduce expenses without compromising quality. In this article, we’ll look at various strategies for cutting costs and streamlining manufacturing processes.

Factors Affecting the Cost of Injection Molds

The cost of injection molding is determined by several factors, including:

Materials

The raw materials used in injection molding can have a major effect on the final cost of your product. High-performance plastics and metals such as engineering thermoplastics and alloys tend to be more costly than commodity plastics.

Tooling Costs

injection mold cost are a significant component of injection molding projects. The complexity of the mold design, number of cavities, and size all factor into tooling costs.

Mold Design

The design of a mold can significantly influence the cost of injection molding. Complex molds with intricate shapes and tight tolerances may require extra machining and lead to longer production times, thus increasing overall costs.

Production Quantities

The number of parts being produced can affect the cost of injection molding. Large production runs help spread out tooling expenses, while smaller batches may end up costing more per part due to higher tooling expenses.

Manufacturing Process

The manufacturing process used to construct an injection mold can have a significant impact on the final cost. While processes like CNC machining and mold flow analysis may add to the upfront expense of creating the mold, they ultimately lead to more efficient production and cost savings in the long run.

Businesses can identify areas to cut costs and optimize their injection molding process by taking into account these variables.

Why do Injection Molds Cost So Much?

Injection molds can be expensive due to several factors:

High Initial Tooling Costs

The initial cost of creating an injection mold can be high due to its complexity and the materials used. Depending on the mold’s size and material used, tooling costs could range anywhere from a few thousand to hundreds of thousands of dollars.

Raw Material Costs

The cost of raw materials used in injection molding can be an important factor. High-performance plastics like engineering-grade thermoplastics may be more costly than commodity plastics.

Manufacturing Costs

The cost of manufacturing an injection mold is also an element. This includes labor, equipment, and facilities. The amount spent can vary depending on where the manufacturer is located and how much automation is used in production.

Design and engineering costs

The cost of designing and engineering an injection mold can be significant. This includes creating 3D models, performing mold flow analysis, as well as testing the mold before production begins.

Though injection molds can be expensive, they are essential for the mass production of high-quality parts in large numbers. Businesses can reduce costs associated with injection molding by optimizing the mold design, using cost-effective materials, and streamlining their production process.

How to Cut Down on Injection Molding Costs

Businesses can utilize several strategies to reduce injection molding costs without compromising quality. These include:

Optimize Mold Design – An optimized mold design can help cut costs associated with injection molding. By simplifying the mold design, minimizing parts count, and using minimal materials, businesses can save on tooling expenses as well as production time for molds.

Utilize High Mold Polish – High mold polish can enhance the surface finish of injection molded parts, eliminating the need for secondary finishing operations and giving the part a sleek, glossy appearance.

Enhance Production Efficiency – Improving production efficiency can reduce the overall cost of injection molding. Strategies for doing so include decreasing cycle times, optimizing the molding process, and minimizing downtime.

Reduce Excess Material Usage – Cutting down the amount of material used during injection molding can help cut costs for raw materials and minimize waste. This can be accomplished by using thinner wall sections, decreasing part size, or redesigning it to require less material.

Textured Surfaces Can Hide Part Defects and Enhance Appearance – Textured surfaces can help hide part defects, eliminating the need for secondary finishing operations.

Utilize Multi-cavity Molds – Multi-cavity molds allow you to produce multiple parts simultaneously, cutting down on cycle time and tooling requirements.

Utilize Aluminum Molds – Aluminum molds are more cost-effective than steel molds and can be produced faster, making them a cost-effective solution for smaller volume production runs.

Implement Intelligent Mold Design – Utilizing intelligent mold design can optimize the molding process and reduce costs associated with injection molding. This includes features like cooling channels, hot runners, and part ejection systems.

Design Self-Making Parts – Designing self-mating parts can reduce the need for separate tooling, thus cutting down on injection molding costs.

Utilize a family mold – A family mold allows for multiple parts to be produced from one mold, which reduces tooling costs and production time.

Reduce Unnecessary Features – Removing unnecessary elements from a part design can help save material, tooling costs, and the overall cost of injection molding.

Discover The Lowest Molding Process

When selecting a molding process, the cost is always an important factor for many businesses. While injection molding is widely used and versatile, other molding processes may be more cost effective for certain applications. Two popular alternatives to injection molding are blow molding and thermoforming.

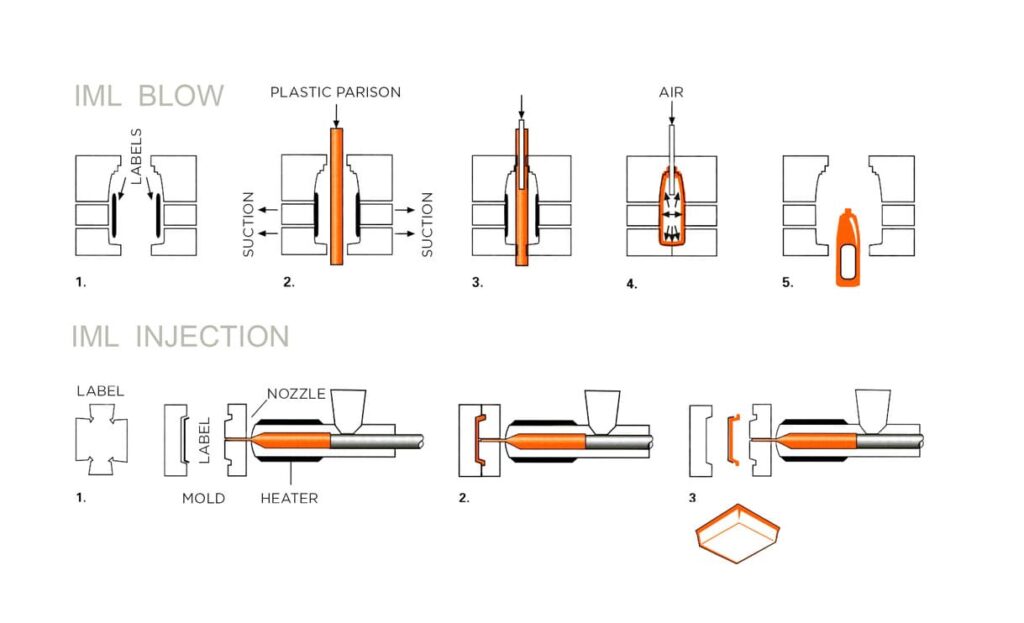

Blow Molding – Blow molding is a manufacturing process used to produce hollow plastic parts such as bottles and containers. This involves melting plastic and then blowing it into a mold to shape it into the desired shape. In certain instances, blow molding may be more cost-effective than injection molding, particularly for large production runs.

Thermoforming – Thermoforming is a manufacturing technique used to fabricate plastic parts by heating a sheet of plastic and then pressing it into shape with a mold. As an economical alternative to injection molding for large, simple parts with low to medium production quantities, thermoforming can be a viable option

Blowing molding and thermoforming may be more cost-effective for certain applications than injection molding, however, they may not be suitable for producing complex parts with tight tolerances. Businesses must carefully weigh their manufacturing needs against the pros and cons of each molding process before making a final decision.

Overall, the most cost-effective molding process will depend on the specific requirements of both the business and the product being manufactured. By working with experienced mold makers and exploring all available options, businesses can find the most cost-effective solution to their manufacturing problems

How Much Does it Cost to Create an Injection Mold?

The cost of creating an injection mold can vary significantly based on several factors, including:

The complexity of Mold Design – The complexity of a mold design can significantly influence its cost. More intricate shapes and tight tolerances may necessitate additional machining and production time, increasing overall costs.

Number of Cavities – The number of cavities in a mold can affect its cost, as multiple cavities allow you to produce more parts simultaneously and reduce per-part costs.

Size of the Mold – The size of a mold can significantly impact its cost, as larger ones require more material and may need additional equipment to create, thus raising overall expenses.

Material Used – The material used to construct an injection mold can have an impact on cost. Steel molds tend to be more expensive than aluminum ones, however, they tend to be stronger and last longer.

The cost to create an injection mold can range anywhere from several thousand to several hundred thousand dollars, depending on the factors mentioned above. For simple molds with one cavity, prices may be as low as $2,000 to $5,000; whereas complex designs featuring multiple cavities and intricate designs could easily reach upwards of $100,000 or more.

Businesses must carefully assess the design and specifications of an injection mold to get value for their investment. By optimizing mold design and working with experienced mold makers, businesses can reduce costs while maintaining top-quality standards.

Conclusion

In conclusion, injection molding is an integrated manufacturing process for producing high-quality parts and products in large volumes. While it can be cost-effective, initial tooling costs can be significant. Therefore, businesses must find ways to reduce expenses without sacrificing quality when using injection molding services.

Optimizing mold design, using high mold polish, increasing production efficiency, eliminating excess material, using multi-cavity molds or aluminum molds, incorporating intelligent mold design principles such as self-mating parts or using a family mold, eliminating unnecessary features and considering rapid injection molding can significantly reduce costs associated with injection molding.

Finding cost-effective solutions in the manufacturing industry is essential for maintaining a competitive edge and increasing profitability. By carefully considering factors that affect injection molding costs and applying strategies outlined in this article, businesses can optimize their process and achieve long-term success.