Thailand is located in the middle of Indochina Peninsula in Southeast Asia. It borders Myanmar and the Andaman Sea in the west, Laos in the northeast, Cambodia in the southeast, and Malaysia in the south.

Thailand is also a member and founding member of the Association of Southeast Asian Nations. Southeast Asian Association (ASEAN) is a free trade area with a large number of consumers and a large coverage area in the world. It is also known as the “third largest economy in the future” after the European Union and the North American Free Trade Area.

Are you looking for the right injection mold supplier in Thailand? We have compiled the top 10 injection molding suppliers in Thailand list for you to pick as below:

Top 10 Injection Molding Companies In Thailand

1. Sakura Tech (Thailand) Ltd

Location: Pluakdeang, Rayong, Thailand

Company type: Manufacturing

Year founded: 1995

The number of employees: 200-299

Main Services: Tool Design, Prototyping, Tool&Die Fabrication, Injection Moulding, Secondary& Value Added Process

Sakura Tech (Thailand) Ltd Company Profile

Established since 1995, Sakura Tech is now one of the leading providers of one-stop plastics soluions, from the initial design stage to final deliver.

With reputable clients in the automotive, medical, electronic and packaging industries, they are able to provide the value-added support for customers in managing suppliers as well as vertical integration.

Sakura Tech strives for global recognitions in competitive plastics solutions through technological capabilities balanced with social and environmental responsibility.

2. Jet-Thai

Location: Samut Prakan, Thailand

Company type: Manufacturing

Year founded: 1992

The number of employees: 100-199

Main Services: Plastic Mold Injection, Mold/Tooling, Pad&Silk Screen Printing

Jet-Thai Plastic Industries Company Profile

Jet-Thai Plastic Industries was established in 1992 at the Bangpoo Industrial Estate of Samut Prakan province.

Their mission is to be the premier supplier of choice for plastic mold injection components by striking the perfect balance between quality, punctuality, and cost. They strive to achieve this goal by continually investing in their people, technology, and system.

Jet-Thai operates injection machines ranging from 20 to 650 tons clamping force. They are experienced in a wide variety of thermoplastics including, but not limited to: ABS, PA, PBT, PC, PC/ABS, PPE/PS, and glass fiber applications. They have all necessary auxiliary equipment to ensure optimal production conditions.

3. Jet Industries

Location: Samutsakorn,Thailand

Company type: Manufacturing

Year founded: 1982

The number of employees: 200-299

Main Services: Molds design, Injection molding, Molds repairment and Maintenance

Jet Industries Company Profile

Jet Industries was established in 1982, the company is a Taiwanese enterprise that set up its office and facilities in Thailand. It owns some of the most effective in-house machines to support high-technology injection moldings processes, such as CNC milling, grinding, EDM, milling, lathe, drilling, sawing, and laser welding.

Most of their clients are manufacturers in the consumer electronics or automobile industries, such as calculators, fax machines, LCD and LED TV, air conditioners, washing machines, and refrigerators.

The company also has a number of sustainability and quality certifications that include several ISO certifications, and also an environment-friendly certificate from Canon and Sony.

In addition, the company obtained the Outstanding Overseas Taiwanese SMEs Award, which evaluates a company based on its management systems, innovation, marketability, human resource management, corporate responsibility, and financial management.

4. Sheng Cheng (Thailand) Co., LTD

Location: Bangkok, Thailand

Company type: Manufacturing

Year founded: 1986

The number of employees: 200-299

Main Services: Manufacturing injection molding products

Sheng Cheng (Thailand) Co., LTD Company Profile

Established and found in 1982, Sheng Cheng(Thailand)Co.,Ltd. specializes in providing high quality products from leading manufacturers in Taiwan to the plastic industry in Thailand.

With more than 30 years of experience, they have been providing machinery and industrial solutions for the Thai market. Their company imports and trades injection molding products, Auxiliaries, and other plastic related parts and equipments.

Their company has constantly been on track with the economic growth and development of the plastic industry in Thailand, evolving and adapting themselves to the ever changing technologies.

Their aim is to provide high-quality and cutting edge technologies for plastic and other related sectors, and to foster the needs of their customers. They support all their customers with the highest degree of integrity, efficiency and respoonsibility.

5. Kasem International Co. Ltd

Location: Samutsakhon, Thailand

Company type: Manufacturing

Year founded: 2003

The number of employees: 700-799

Main Services: Manufacturing Engineering, Mold Making, Injection Molding, Strech Blow Molding, Assembly

Kasem International Co. Ltd. Company Profile

Kasem International Co. Ltd. was established in March 2003 to focus on manufacturing of food contact products which need very high hygienic manufacturing and quality processes.

Their state of the art manufacturing facility was built with a focus on quality of products making it a reliable producer of high quality food contact products in baby feeding and kitchenware industry for global market.

Kasem International specializes in the production of feeding bottles, Liquid Silicon rubber nipples, pacifiers and food storage box as well as many other practical and innovative products to assist modern age parents to simplify their life during best years of family formation.

The company’s consistently excellent standards of production, quality process and customer care have made them the choice of leading brands and retailers in 20 countries across the globe. They are recognised for delivering innovative products, manufacturing excellence and technical solutions.

6. Hi-Q Plas

Location: Pathumthani, Thailand

Company type: Manufacturing

Year founded: 1990

The number of employees: 100-199

Main Services: Mold making, Plastic injection molding, Secondary process in plastic finishing, Mold maintenance, Product assembly, Project design and development

Hi-Q Plas Company Profile

With over 20 years of experience in plastic injection and mold making. They are a leading plastic injection molding company providing total solutions from in-house mold making, mold modification and repair to plastic injection and secondary process such as silk screening, color spraying, pad printing, color dropping, UV coating, ultrasonic and hot stamping. They also offer basic assembly process for customers if required.

They are specialized in engineering plastic components for electronic, automotive, household, cosmetics, medical device and solar energy housing component towards any other plastic items which requires quality and precision.

With more than 150 skilled staffs and their strong commitment, they deliver highest quality products and services for highest satisfactions to their valued customers.

7. SANKO PLASTICS (THAILAND) CO., LTD

Location: Chonburi, Thailand

Company type: Manufacturing

Year founded: 2019

The number of employees: 100-199

Main products: Injection moulding of plastic products for logistics and warehousing

SANKO PLASTICS (THAILAND) CO., LTD. Company Profile

Sanko Plastics (Thailand) Co., Ltd. was founded in Thailand in 2019,They have paid-in capital around 456,000,000 THB. The shareholder were SANKO Co., Ltd. (100 %) . They establishment on May 2019 and then was start production line on March 2021.

Sanko Plastics (Thailand) Co., Ltd. develops and manufactures products especially for containers/ boxes for industrial use and large plastic products for logistics-use. Total Plant area space : 24,300 m2.

8. Supavut Industry CO., LTD

Location: Chonburi, Thailand

Company type: Manufacturing

Year founded: 1997

The number of employees: 100-199

Main Services: Mold Manufacture, Injection Molding, Blow Molding and Paint Shop

Supavut Industry Company Profile

Supavut Industry has acquired advanced die production technology and management techniques, as well as building on practical experience, and has developed and perfected quality control procedures to meet customers’ world-class product quality requirements.

Mold manufacture and design for plastic automotive parts are mostly made to order for auto makers for both the domestic and overseas markets. The range of molds includes injection molds and blow molds.

At the same time they pay constant close attention to controlling operating costs and increasing efficiency, so as to ensure competitive pricing and high quality services for their customers.

Brand new high precision machines are used in their injection mold facilities (e.g. CNC 5 axis). CAD & CAE are used for mold design analysis in advance for product process efficiency. A qualified system is controlled to meet customer’s quality requirements and schedule timing are managed.

9. ALCAMI

Location: Rayong, Thailand

Company type: Manufacturing

Year founded: 2001

The number of employees: 100-199

Main Services: Thermoforming, Sheet Extrusion, DI Washing, Injection Moulding, CNC Machining, Mould Fabrication, Assembly and Testing, Sourcing and Trading

ALCAMI Company Profile

Their Rayong facility is located in Industrial Zone Eastern Seaboard, and it houses Alcami Industries and Alcami Extrusion. They have about 6400 m2 of factory floor, with approximately 80 people working here. The building sits on a plot of 8000 m2.

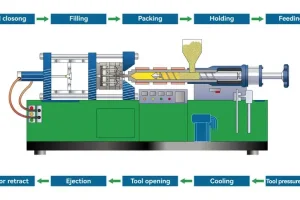

Injection moulding is one of the most widely used production methods for plastic parts and is a cornerstone of Alcami’s production capabilities. Injection moulding involves injecting a heated material into a pattern, called a mould, which then cools into a single-piece part that is high-quality, strong, and replicable.

A diverse range of plastic materials can be used in injection moulding to create parts across many different industries: Plastic packaging, Food & beverages, Consumer electronics , Medical sector, Injection moulding is highly repeatable, which makes it great for brand consistency and part reliability. This also makes injection moulding extremely efficient and cost-effective for high volume production.

10. TS Molymer Co.,Ltd

Location: Samut Prakan, Thailand

Company type: Manufacturing

Year founded: 1993

The number of employees: 100-199

Main Products: Automotive Parts, Electronics Parts, Home Appliance

TS Molymer Co.,Ltd. Company Profile

TS Molymer Co.,Ltd. is one leading plastic injection molding company and mold manufacturer of plastic mold making.

TS Molymer was established in 1993 under BOI privilege for plastic products such as Automotive,Car Audio, Electronic, Home Appliance and Office Automation.

Beside, TS Molymer service full secondary process of spray,screen,pad printing, UV painting, Ultrasonic Welding, Laser Marking and sub-assembly unit by employing a team of experienced, well-trained operators and advance technology in order to make high quality products, prompt product delivery, flexibility, competitive prices and provide best services to our local and oversea customers in China, Hongkong, Indonesia ,India, Japan,Australia, Mexico and USA.

TS Molymer has many varieties of Plastic Injection molding and insert molding processes that range from 50-850 tons clamping force and in-house experienced plastic mold maker to offer quality injection mold on their precision requirement of each customer.

If you’re looking for more injection molding manufacturers, Also you can choose a Chinese injection mold supplier: Zetar Mold

Zetar Mold

Location: Shanghai, China

Company type: Manufacturing

Year founded: 2005

The number of employees: 201-300

Main product: Plastic Injection Mold, Plastic Injection Molding Manufacturing

Other products: Overmolding Products, Insert Molding Products, 3D printing and CNC Prototyping

Zetar Company Profile

Zetar is a top-end turnkey manufacturing company that helps wholesalers and brand owners fulfill their products.

Zetar has more than 20 English speakers and 7 experienced injection mold design engineers (some of them can also speak English) with technique and english communication, which could make sure fluent communication and offer feasible design solutions.

Now total Zetar has mold making shop in house, 31 sets injection molding machines range from 60T-1100T. which 6 sets are in dust-free room(M7 Class), assembly room and logo printing room. The largest 1100T injection molding machines could produce product weight up to 5100g.

Zetar definitely also has many certificates: TUV, ISO9001 (quality system certification), TS16949 (certification for auto parts making), ISO14001 (certification for showing not harming the environment during whole manufacturing process).

Conclusion

Finding a trustworthy manufacturer nowadays is not that easy, especially that there are a lot of new manufacturers that have emerged just to keep up with the trend. But hopefully, our list was able to help you find the injection molding manufacturer that best suits your requirements. It is recommended to do a background check before creating partnerships with manufacturers because they will play a huge part in the success of your business.