Injection molding is a vital manufacturing process used to produce parts with accurate dimensions.

While tolerance in injection molded pieces refers to the deviation from desired measurements, it directly impacts part fit and function – potentially leading to costly rework or rejection if too large/small.

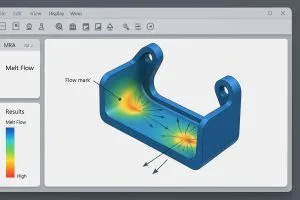

Careful consideration of factors such as temperature gradients, shrinkage rates & material flow can help ensure optimal product tolerances for successful application results.

The material of the molded parts

Different materials have different shrinkage rates, which can impact the final dimensions of the part.

The material choice for a project may have farther-reaching implications than one might expect; different materials shrink at varying rates, which can drastically alter the intended outcome.

Designers must stay aware of this phenomenon to ensure that their final products remain true to plan.

The complexity of the molded parts

Manufacturing components with intricate shapes and features requires finesse to maintain tight tolerances.

Filling the injection mold perfectly while maintaining an even wall thickness is no easy task – but it’s necessary for optimal results!

The condition of the mold

Over time, the precision and accuracy of parts molded in injection molds can erode due to wear and tear.

It’s essential for businesses using these tools to stay vigilant about monitoring their machines’ performance.

The injection molding process

To achieve the desired dimensions of injection molded parts, speed and pressure play a critical role during production.

Controlling these parameters is essential for ensuring that each part produced meets stringent quality standards; some methods to maintain optimal tolerances include regulating mold temperature, adjusting cycle times, or varying material composition.

1) Proper design of the molded parts

Through meticulous engineering, the part can be crafted to minimize distortions due to shrinkage and other variables for optimal final dimensions.

2) Use of a high-quality mold

Producing parts with high-precision features is made much easier when tools are properly maintained. Consistent maintenance leads to tight tolerances and quality components.

3) Control of the molding process

Achieving precise parts requires careful control of the injection molding process.

By ensuring optimal temperature, pressure and speed settings, you can effectively reduce any inconsistencies between desired part dimensions and their produced counterparts.

4) Use of precision measurement tools

Ensuring precision with every part is critical – to maintain the highest standards, advanced measurement tools such as calipers and coordinate measuring machines are employed in order to guarantee that each injection molded component meets its strict dimensional requirements.

Conclusion

From part design to injection molding process control and precise measurement tools, injection molders have several options for achieving exact tolerances in their molded parts.

This can result in improved fit and functionality that meets even the most specific requirements.