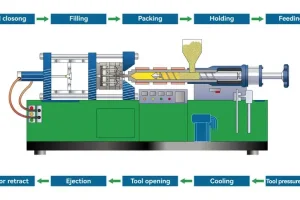

Injection molding has become a vital manufacturing process, deployed by an array of industries to produce plastic parts and components.

It is renowned for its impressive efficiency and uses in the automotive, aerospace, medical, and consumer goods sectors – proving the potential financial advantages it holds.

To experience this success rate first-hand however requires injection molders to effectively satisfy various conditions.

1. The ability to produce parts efficiently and cost-effectively

The production speed of injection molding provides the potential to cut unit fixed costs significantly, providing a direct and substantial boost in profitability.

Highly automated machinery can quickly produce parts at volumes ranging from hundreds up to thousands per hour; dependent on size and complexity on the part itself.

This fast turnaround enhances regulatory approval processes across all industries making them more efficient than ever before!

2. The use of automation and robotics

Automation and robotics can play an important role in the injection molding process, helping to optimize efficiency while decreasing labor costs.

By equipping injection molding machines with automated systems that load and unload cavities as well as monitor plastic processing, manual labor is greatly reduced – delivering financial savings for manufacturers everywhere.

3. The demand for plastic parts and components

Injection molding offers businesses a reliable solution for producing high-quality products.

Its established reputation makes it an attractive proposition providing consistent revenue streams and long lasting customer relationships.

4. The ability to produce high-quality parts

By investing in top-of-the line tooling and equipment, injection molders can create parts that meet the customer’s exact requirements.

This higher degree of precision gives businesses a competitive edge – generating repeat orders and helping to boost overall profits.

5. The ability to offer a wide range of services

Injection molding businesses have the potential to reach greater profitability by offering a suite of services that extend beyond the core process.

By providing assistance with design and prototyping, as well as secondary operations such as assembly or packaging, companies can differentiate from competitors in order to acquire more customers.

6. The ability to adapt and innovate

Injection molding businesses can stay ahead of the competition and enhance their profitability by adapting to customer-specific needs, staying up-to-date with current market trends, and introducing innovative solutions.

Keeping abreast of these areas is key for entrepreneurs looking to make a mark in this ever evolving industry.

Conclusion

Profiting from injection molding is a reality for those who are knowledgeable and experienced in the field, allowing them to take advantage of market opportunities.

By delivering quality products and services, organizations can benefit financially through this industry sector.