Injection molding is a highly specialized manufacturing process allowing for the creation of intricate parts and components – ranging from toys to automotive pieces.

With an exactitude in controlling many various parameters, this old-fashioned technique creates consistent quality regardless of complexity that exceeds all expectations.

Carefully tailored settings are the key to success when it comes to injection molding – nothing is left up to chance. Fine-tuned parameters ensure that each project runs as efficiently and effectively as possible.

These parameters include:

a. The temperature of the plastic

b. The injection speed

c. The pressure applied to the plastic

d. The cooling time.

e. Other factors

Determine the type of plastic that will be used

To explore the ideal plastic injection molding process, it is essential to assess the material’s parameters.

Various plastics have unique melting points that must be considered for setting up temperatures and understanding how they’ll impact other attributes such as viscosity and flow rate during formation.

Optimizing these characteristics can create an efficient system with refined results!

The injection speed

After identifying the necessary material, setting an appropriate injection speed is critical for successful part formation.

The rate of injection determines how quickly and evenly the molten plastic fills into an injection mold; too slow can lead to incomplete parts while too fast could result in overfill damage or compromise the integrity of a molded piece.

All parameters must be taken into consideration when determining proper injection speeds – making sure each final injection molding products meet expectations both aesthetically and functionally!

The pressure applied to the plastic

Finding the precise injection pressure for a plastic part is an important factor in achieving its desired output.

By setting this parameter correctly, we can ensure that the material will fill every corner of the injection mold without flaws or deformities.

Too high and it could lead to cracking – too low may compromise strength and durability after production has been completed. Fine-tuning these details sets us on course for successful outcomes from the projects!

The cooling time

Precision cooling is a critical factor in successful injection molding. Too short and the finished product may be weak or poorly formed, while too long can lead to uneven shrinkage and warping of the part.

With that being said, it’s essential for manufacturers to take into account all necessary variables when setting pressure levels – including determining an ideal cool-down period so as to ensure optimal quality and strength from each injection molded component!

Other factors

In order to optimize the injection molding process, it is essential that engineers understand and implement several factors.

Not only must they consider plastic materials characteristics, but also pay close attention to the equipment capabilities as well as assess the size and shape of injection molds requirements during production runs with varying volumes.

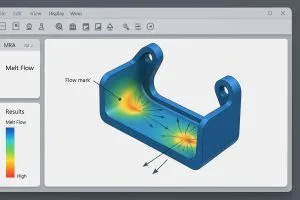

With the parameters for injection molding set and carefully monitored, specialized equipment along with cutting-edge software is used to ensure everything runs smoothly.

Sensors in the injection molding machine can be utilized to precisely track temperature, speed, and pressure -all while monitoring any irregularities or deviations from optimal conditions. This automated process allows us to maintain production quality at its highest level of precision!

Conclusion

The injection molding process requires precision to create high-quality parts and components.

By taking into account the key parameters of temperature, speed, pressure and cooling time – a methodical approach will ensure successful results with minimal defects or issues.