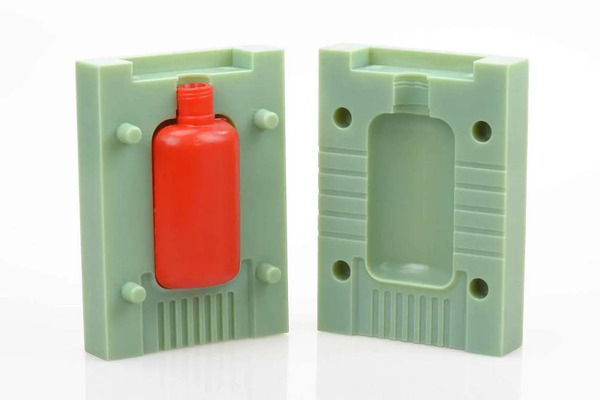

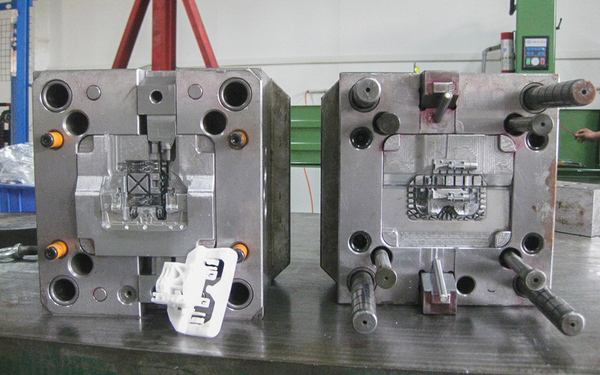

3D printing is transforming the injection molding industry by enabling faster, more cost-effective mold production. This process allows for the rapid prototyping of complex molds, reducing lead times and costs in manufacturing.

3D printing for injection molds offers faster prototyping, reduced costs, and the ability to produce complex geometries. It is commonly used in industries such as automotive, consumer electronics, and medical devices. Benefits include faster turnaround times, the ability to test designs quickly, and lower initial investment compared to traditional methods.

While 3D printing offers numerous benefits, it’s important to understand the limitations and considerations of using this technology for mold-making. Explore how 3D-printed molds compare with traditional molds in terms of durability and production scalability.

3D printing can create functional injection molds.True

3D printing can produce molds that are suitable for low-volume runs and rapid prototyping, allowing faster iteration and testing of product designs.

3D printing is the best method for making all injection molds.False

While 3D printing is excellent for prototyping and low-volume production, traditional molds made of metal are generally more durable and cost-effective for high-volume production runs.

How to Design Parts for 3D Printing Injection Molds?

To design parts for 3D printing injection molds, focus on features like draft angles, wall thickness, and part geometry to ensure smooth mold filling and easy removal. Use 3D printing’s flexibility to create complex geometries and reduce traditional tooling costs. Important considerations include material selection and print orientation to avoid weak spots.

What is 3D Printing?

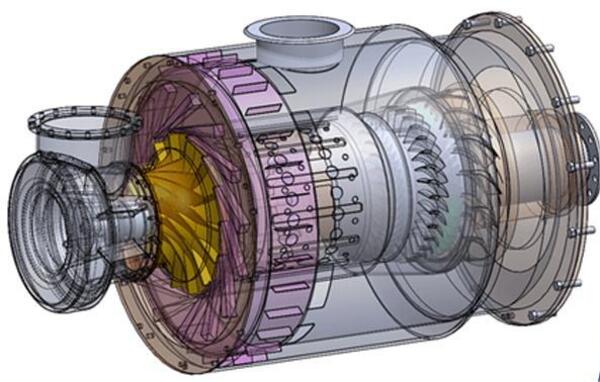

3D printing, also known as additive manufacturing technology, is a method of constructing three-dimensional objects based on three-dimensional CAD model files, using materials such as powder, filament, or sheet through layered manufacturing and layer-by-layer superposition technology.

What is Used to Create Parts for 3D Printing?

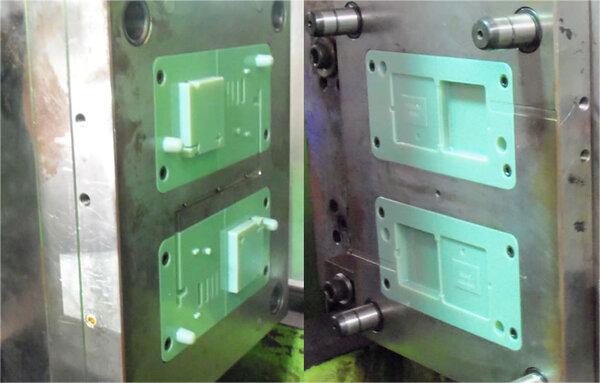

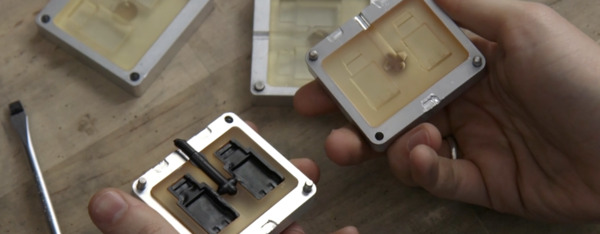

Mount the mold into the metal frame and prepare it for injection molding. To create a mold, you must first have a 3D model of the part you wish to produce. Parts are designed using Computer-Aided Design (CAD) software while adhering to the principles of injection molding.

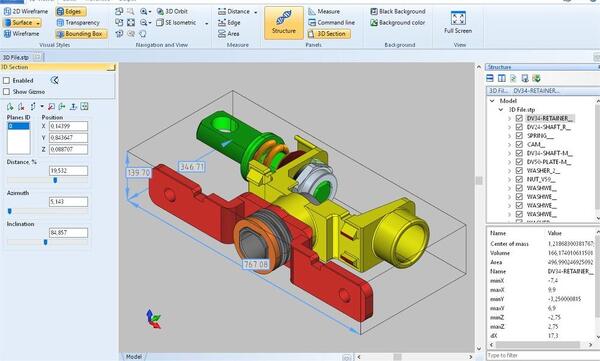

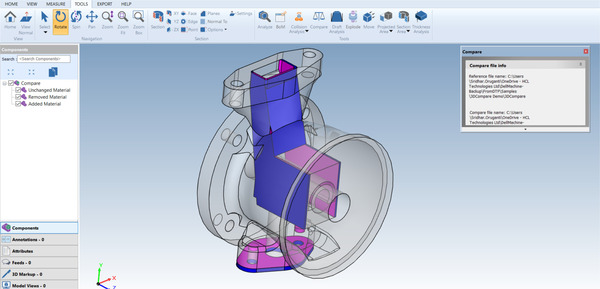

CAD software is a computer technology application used for creating and editing design graphics. It finds applications across various fields including machinery, architecture, home furnishing, and textiles. The key functions of CAD software encompass plane drawing, enabling users to generate fundamental graphic elements like lines, circles, ellipses, polygons, and splines.

These programs also offer drawing aids such as orthogonality, object snapping, and polar tracking. CAD software caters not only to 2D drafting and intricate rendering but also to design documentation and fundamental 3D design.

CAD is an automated computer-aided design software proficient in producing both two-dimensional drawings and basic three-dimensional designs. Users can generate drawings without needing programming knowledge, rendering it widely utilized globally in sectors spanning civil construction, decoration, and industry. Its applications include drawing, engineering drawings, the electronics industry, clothing processing, and more.

Key CAD functions comprise plane drawing, auxiliary drawing tools, graphic editing, dimensioning, layer management, and three-dimensional drawing capabilities. Moreover, CAD software provides robust graphic editing features for tasks such as moving, copying, rotating, arraying, stretching, extending, trimming, and scaling objects. Specific CAD applications focus on precise drawing for plane referencing, creating intricate graphics, using model libraries, and playing a significant role in urban planning, garden design, electronics, fashion design, and various other industries.

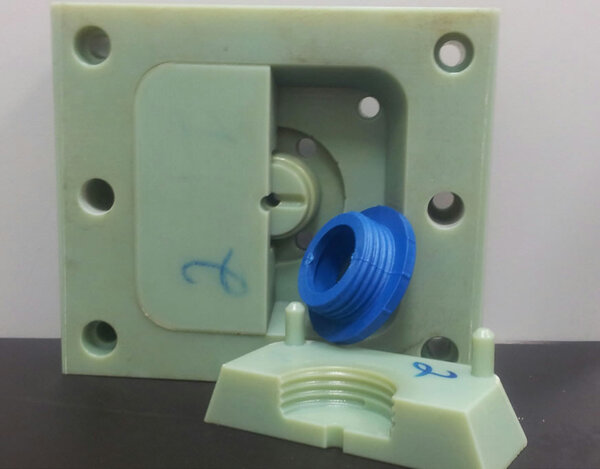

What Kind of Mold to Design?

Using the watch strap as an example, the mold design utilizes 50-micron high-temperature resin V2, known for its excellent quality and exceptional resolution. To ensure optimal release, apply 40 to 50 sprays of standard mold release spray per layer.

Printing at a precise layer height of 50 microns enhances the spraying effect, yielding an ultra-smooth surface finish that facilitates easy removal of parts from the mold. The 3D printed mold necessitates no supplementary cooling, and there are no signs of any adverse reactions between the injection material and the printing resin.

What Kind of Printing Materials to Choose?

The best printing material depends on the specific needs of your project. For 3D printing, PLA is ideal for easy use, while ABS offers greater strength. For traditional printing, paper quality and ink type are essential for durability and print quality. Consider factors like temperature resistance, flexibility, and eco-friendliness when making your selection.

With the continuous advancement of 3D printing technology, the performance of 3D printing materials is constantly improving, enhancing the functions of the produced 3D printing products. The use of 3D printing to manufacture end-use tools (End Parts) is increasingly common.

What are the requirements for 3D printing materials? The development of 3D printing technology largely depends on the progress of materials. Today, there are various types of 3D printing materials, each tailored for specific 3D printing technologies.

For instance, filaments are utilized in FDM printing technology1. Currently, the most prevalent filaments are 1.75mm in diameter, with a few also available in 3mm diameter.Common ones include PLA, ABS, TPU, etc. Liquid consumables are used in light-curing technology, usually photosensitive resins.

Powdered consumables are often printed using SLS technology. The most common ones are nylon, such as PA12, PA11, PA-GF, etc. Most of the consumables for metal 3D printing are in powder form, and SLM and EBM technologies are the most common. In recent years, metal 3D printing using FDM technology has also appeared.

However, because this type of metal 3D filament is not 100% metal filament, but a filament made of a plastic base with metal particles evenly arranged, professional post-processing such as degreasing and sintering is required after model printing is completed to remove the plastic components before a metal print can be obtained. This process is often referred to as indirect metal 3D printing.

3D Printing Materials Suitable for Manufacturing Injection Molds must Possess the Following Characteristics

High detail expression: Injection molds necessitate high dimensional accuracy and smooth surfaces. Molds with high precision will yield parts of equally high precision.

High temperature resistance: A high heat deflection temperature (HDT) is crucial, not only to ensure that the mold does not fail during the injection process but also to allow for more precise control of the process.

High stiffness: The mold must maintain good dimensional accuracy over multiple runs and withstand high pressures without deformation during material injection.

What are the Main 3D Printing Processes?

3D printing involves layering materials, such as plastics or metals, to create objects directly from digital models. The key stages are designing the model, preparing the printer, and building the object layer by layer. Common methods include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). This technology offers benefits like rapid prototyping, cost savings in small batches, and the ability to create complex geometries.

Unlike traditional printers, which are flat, 3D printers are three-dimensional and consist of control components, mechanical components, print heads, consumables, and media. What is its principle? After designing a three-dimensional image on the computer, it is printed layer by layer using plastic or other materials. The continuous repetition of the plane becomes the three-dimensional image. The following is the main process of 3D printing.

Modeling

Generating a digital model is the first step in the 3D printing process. The most common method of generating digital models is through computer-aided design software (CAD). There are numerous free and professional CAD programs that are compatible with 3D printing. The most critical step is creating the CAD or CG model, which is also the core part of the modeling software.

Model Partition

After using a computer for 3D modeling, the design needs to be segmented and layered before being imported into a printer for step-by-step printing. Common file formats for this process include STL and PLY. If you require full-color printing, the preferred choice is usually PLY due to its high resolution capabilities.

Data Import

Once the model design is completed, simply input it into the 3D printer using a USB flash drive or data cable. Next, configure the printing settings. Once the settings are finalized, commence the 3D printer and initiate the printing process. Through a series of intricate stages, a collection of meticulously crafted models will be produced, suitable for immediate utilization in manufacturing processes, including advanced material applications.

What is Preparation for Injection Molding and Testing Models?

Preparation for injection molding involves creating accurate CAD models, selecting the right material, and ensuring the mold is properly designed and tested. Key aspects include simulating the injection molding process, conducting trial runs, and adjusting parameters such as temperature, pressure, and speed. These steps help to identify potential issues early, reducing defects and enhancing the efficiency of production.

What is Injection Molding?

Injection molding is a prevalent manufacturing process in the plastics industry. Essentially, molten plastic is injected into a mold cavity, allowed to cool and harden, and then the mold is opened to remove the plastic piece.

What is a Test Model?

The test model, also known as a 3D model, is specifically designed to evaluate various printing properties of 3D printers or materials. Common 3D printer test models include 3DBenchy, a multi-functional assembly board, XYZ cube, constant temperature tower, PolyPearl, accuracy test, leveling test, tilt angle, six-sided bridge, and combination kit.

Among these, the most iconic is 3DBenchy – renowned as a specialized model for 3D printing testing and the most widely used test model. It encompasses all the essential elements for evaluating 3D printing capabilities. For instance, its hull features a smooth curved surface that allows testing of printing suspended curved surfaces without support.

The model is perfectly symmetrical on both sides, facilitating the assessment of X-Y axis accuracy and identifying any deformations. Additionally, the intricate text on the ship serves to gauge the printer\’s print resolution, while round chimneys and windows are ideal for testing the accuracy of printed circles.

What are the Main Post-Molding Treatments?

Post-molding treatments include processes such as trimming, surface finishing, painting, and assembly. These steps help improve the part’s surface quality, remove excess material, and ensure it fits specific design requirements. Common treatments are used in industries like automotive, electronics, and medical device manufacturing.

After removing the support, the workpiece needs to be separated from the base plate, usually using wire cutting, sawing, etc. Wire cutting separation takes a long time and is mostly used to separate workpieces with many supports and thin-walled support joints because this separation method is relatively gentle and will not cause deformation of the workpiece. When the workpiece is small, has few supports, or the support connection is a solid structure, in order to save separation time, a chisel can also be used to directly remove the workpiece.

After the 3D printing is completed, the printed workpiece is submerged in the powder. When picking up the part, the waste generated by the sintering is first removed to prevent the waste from contaminating the powder; then the workbench is raised, and preliminary powder cleaning is performed in the processing warehouse. Use a brush to sweep the unsintered powder attached to the surface of the workpiece into the powder recovery tank for recycling and finally take out the workpiece and substrate together.

Powder Cleaning

This powder cleaning method is primarily targeted towards the cooling channels of the mold. You can utilize a brush to directly clean the powder, or employ auxiliary equipment like a vacuum cleaner or hair dryer to eliminate the powder trapped within the cooling channel. The configuration of the cooling channel significantly impacts the complexity of powder cleaning, including factors like diameter, channel curvature radius, etc.

Sandblasting

Sandblasting involves the use of compressed air to propel a high-speed jet beam that sprays abrasive materials (such as copper ore, quartz sand, emery, iron sand, Hainan sand, etc.) onto the surface of the workpiece requiring processing. This process aims to enhance the appearance or shape of the workpiece, inducing specific performance modifications.

Other technical advantages of the Selective Laser Melting (SLM) process include the ability to mold workpieces with complex, irregular structures. The injection mold features internal cooling channels and various external structural elements like bosses and concave holes.

Currently, challenges arise from the relatively large surface roughness of workpieces produced by the SLM process and the complexity of controlling accuracy.

As a result, direct application of SLM-molded molds in plastic molding, particularly for parts with high surface finish and precision specifications, remains not fully developed. Therefore, additional traditional machining methods are necessary for subsequent processing to achieve the required mold accuracy, surface quality, and other specifications.

What are the Main Principles of 3D Printing Technology?

3D printing creates objects layer by layer from digital files, enabling rapid prototyping and on-demand production. Key principles include material extrusion, selective laser sintering, and photopolymerization. It is commonly used in aerospace, healthcare, automotive, and consumer goods. Key benefits include reduced material waste, faster design iterations, and lower production costs. In practice, the principles of 3D printing technology mainly include the following aspects:

Light-Curing Molding

Regarding the working principle of light-curing molding, it mainly utilizes a laser or other heat-sensitive materials illuminated by a light source. This technology is currently one of the most intensively researched and fastest-growing technologies. It is primarily used in the production of parts with relatively complex structures and high precision.

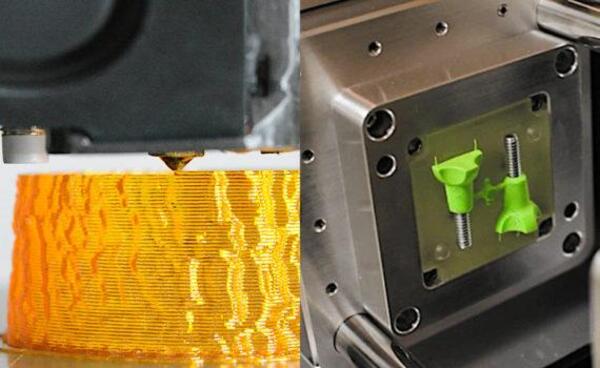

Fused Deposition Rapid Prototyping

In the realm of fused deposition rapid prototyping, it is commonly referred to as fused filament fabrication (FFF). The process entails heating and melting a thermoplastic filament, which is then extruded through a nozzle before being solidified into the desired shape. This iterative layering of material is crucial for ensuring the structural integrity and quality of the final product. FFF stands as the predominant technology employed within the domain of 3D printing due to its efficiency and widespread adoption.

Three-Dimensional Powder Bonding

In three-dimensional powder bonding, the main principle is for operators to effectively utilize specific nozzles to spray adhesive onto the designated area. This process enables the bonding of the powder with other materials, thereby creating a more refined cross-sectional shape. Repeatability is crucial for successful implementation, allowing for enhanced productivity. This technique is commonly utilized in the realm of 3D printing technology.

Conclusion

Product designers, entrepreneurs, and educators utilize mold making to replicate parts across various industries. Injection molding stands out as a versatile process commonly employed to manufacture these parts in large quantities.

High-volume injection molding2proves to be cost-effective, efficient, repeatable, and results in top-notch parts. Nonetheless, for smaller batches, the expenses and time associated with crafting molds from typical mold metals pose challenges to the procedure, frequently hindering access to injection molding of this magnitude for numerous enterprises.

In summary, utilizing 3D printing for creating injection molds involves designing parts, creating molds, selecting printing materials, 3D printing the molds, preparing for injection molding, testing models, and post-processing the injection molded parts3.

With the continued advancement of science and technology in our country, the expertise in 3D printing4 technology has significantly progressed. This technology is predominantly employed in various sectors such as laboratories, businesses, and households.

The capability to process curved surfaces using 3D technology offers advantages that surpass those of conventional molding and processing techniques. The integration of 3D technology in the current mold industry has notably enhanced our country\’s manufacturing standards.

-

Learn about FDM Technology : FDM is an additive manufacturing process also known as 3D printing. ↩

-

Learn about HIGH VOLUME INJECTION MOLDING: AN OVERVIEW : High volume injection molding is a specialized plastic manufacturing process . ↩

-

Learn about Post processing of Injection molded parts : Post-processing of injection molded parts is very important since Injection molding forms plain plastic parts. ↩

-

Learn about 3D Printing: What It Is, How It Works, Examples : Three-dimensional (3D) printing is an additive manufacturing process that creates a physical object from a digital design. ↩